Nothing is quite like World of Asphalt. We were there for all three days, and still, there was too much that any one person could see in that amount of time. Here's a place to check and see that you didn't miss any of the big reveals, products, or events.

Just a short recap, while there were plenty of new or updated pavers, mills, and compactors, there was a huge emphasis on technology. There were more technology companies present than ever before. Additionally, the legacy brands came with both barrels loaded in terms of technology. Wirtgen, Caterpillar, Dynapac, BOMAG, Astec, Weiler, and many others introduced proprietary telematics and/or monitoring software; or integrations with third party vendors offering deeper data and analytics. Many of those items we've detailed below or elsewhere in our video library.

Everyone seemingly knows the same thing: We have to get the data.

The good news is that the newest generation of iron can match the demands that data represents. They're more precise, more efficient, easier to control, and come with more support than ever before. There's likely never been a better time to upgrade your fleet. If you've been waiting for the right time to get the most bang for your buck, this just might be it.

Additionally, follow the Asphalt Contractor and Pavement Maintenance social media channels for videos and photos from the World of Asphalt trade show floor.

12:00 pm CST - 3/27/24

The End Of The Line

All good things must come to an end, and this was one of the very best. It's time to leave Nashville behind, but it won't be soon forgotten. We hope you've enjoyed our LIVE coverage of the event, and hope to improve and refine this concept for shows to come in the future. We strive to bring the best and most informative coverage for our industry. Thanks for following along! See you on the road!

11:15pm CST - 3/27/24

TYMCO Stands On It's Consistency

The fact that a model any type of machinery could be in production for twenty years is wild. That's what TYMCO came to highlight at the 2024 World of Asphalt. The 500X is a solid and dependable machine, and it's uses range from streets, parking lots, to being a part of roadway construction trains. There isn't much that it can't pick up!

The TYMCO 500X.Chantal Zimmermann

The TYMCO 500X.Chantal Zimmermann

The Model 500X TYMCO sweeper key features:

- A multi-dump high sweeper that can empty debris directly into dump trucks to keep the sweeper operating continuously

- It has strong safety features to safely lift and handle heavy loads with its dump bed

- Powered by a 115 horsepower John Deere engine for powerful sweeping capability

- It has been in production for over 20 years, demonstrating its proven and reliable performance

- It has a stainless steel body for durability

10:30 am CST - 3/27/24

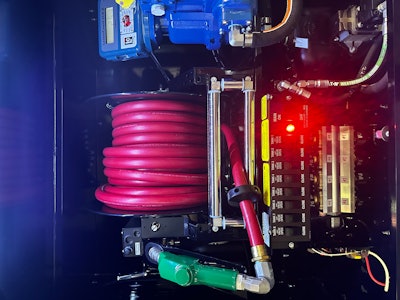

Caterpillar Upgrades Safety and Exhaust Systems for the PM300 Series Cold Planer

Jameson Smeija, senior sales consultant for Caterpillar gave a short presentation about the newest additional features and highlights for the PM312 cold planer to a crowded group of media, while linking it all back the telematic platform Caterpillar offers called VisionLink.

9:47 am CST - 3/27/24

MEEKER Now Manufacturing Silos For Asphalt Plants

Well known for providing machinery, parts, and components for asphalt plants, MEEKER is getting ready to ship its first silos in the coming months. While they didn't have one at the booth during World of Asphalt, Asphalt Contractor magazine will be visiting one of these silos in a future issue. So, if you aren't subscribed yet, they are free to contractors nationwide, subscribe here.

Brandon Noel

Brandon Noel

9:13 am CST - 3/27/24

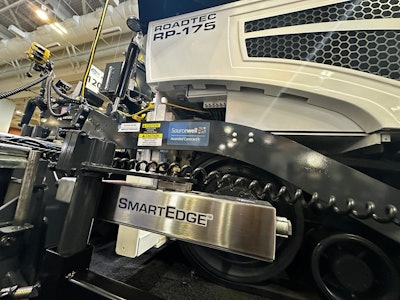

The SmartEdge Revolution

Matching the seam will never be the same, but it might be a while before you get your hands on it. Astec's patent pending SmartEdge joint detection system is truly a leap forward in paving technology. Speaking with Tom Travers at the Astec booth this morning, he explained that they spent a lengthy development period making sure they got it right.

Astec's SmartEdge laser based join detection system.Brandon Noel

Astec's SmartEdge laser based join detection system.Brandon Noel

Part of the reason for the time it took to get here from concept had to do with the failure of previous sensor systems. The environment of asphalt paving can shift rapidly, dealing with intense heat, humidity, vibrations, smoke, and other particulates. The SmartEdge has been tested thoroughly in every paving environment you can think of, and it gets the job done.

"We're trying to buy back the mental capacity of our our workers. So they're, they're not so taxed at the end of the day," said Travers.

Currently, the new autonomous join matching tech is only available on the new F Type platform from Astec, and won't be available until late in the third quarter this year. Orders for the model are already a year out, so, you'll need to get in line quickly. Travers did indicate that the technology would likely be included in future models as they are updated or redesigned, but it isn't backwards compatible.

The reason why is that it is fully integrated into the paver's hydraulics. The two systems have to fully work together, be designed to work together. It's capable of matching seems down to the micron level. This allows for the worker to focus on material.

The SmartEdge sensor attached to the new F Type RP-175 highway class paver. The only model with the tech.Brandon Noel

The SmartEdge sensor attached to the new F Type RP-175 highway class paver. The only model with the tech.Brandon Noel

Some notable features of the SmartEdge:

- Uses sensors to detect and monitor the edge being matched (e.g. joint, curb, barrier) from 0-14 inches away

- Provides parameters to the paver tractor to automatically adjust the screed extension in and out to perfectly match the edge

- Holds the edge match at an extremely high tolerance, finer than can be imagined by a human

- Works in all situations including corners, radii, smoke, and heat which disrupted previous systems

- Fully vetted and developed by the company's advanced research and development group

- Speaks to the paver's hydraulic system to automatically adjust the screed extension for a perfect joint match

DAY 2

5:00 pm CST - 3/26/24

TWO DOWN AND ONE TO GO!

As this is my first time to World of Asphalt, I have to admit that this thing is a huge machine. I've been to CONEXPO, but WOA has no lulls, no slow-downs, it just keeps churning all day long. As the second day comes to a close, our awesome team from Forconstructionpros and IronMarkets have done an incredible job. JUST ONE MORE DAY!

See you tomorrow, WOA!

A visitor to the trade show floor.Jodi Sage

A visitor to the trade show floor.Jodi Sage

4:44 pm CST - 3/26/24

Caterpillar Press Conference: Part 1, Compaction

Cary Bryant from Caterpillar give a short talk about all the new features on the company's highway class tandem rollers.

3:57 pm CST - 3/26/24

Topcon Shows Off Major Tech Upgrades

Technology has really taken off in the asphalt industry, as the workers, owners, and executives at every level of the job are awakening to the power of capturing, owning, and analyzing their data. There's a power to it, and there is no shortage of companies wanting to capitalize on this sea-change. Every size of contractor, producer, paver, or earthworks company wants to gain that edge. In that environment, Topcon brought two new pieces of technology aimed to help precisely in this way.

Topcon's new and upgraded MC-X3 machine control box.Brandon Noel

Topcon's new and upgraded MC-X3 machine control box.Brandon Noel

The MC-X3 machine control gateway is way of capturing machine data, but also programming the work they do in 3D space. It works on any and all major manufacturers, and it can be implemented on anything from pavers, dozers, milling machines, or compactors. The companion software from Topcon is loaded with special profiles for each type of machine and aids in their coordinated use.

Features of the Topcon MC-Max receiver:

- Compact and condensed size compared to previous receivers- Includes all necessary ports

- Directly connects to construction equipment CAN buses for seamless interface with OEM machines

- Acts as the "brain" for machine control functions

Topcon also has an entirely new offering in the form of a road sensor called the "Smooth Ride." The surface radar scanar is able to travel at highway speeds, without the need to close roads, in full traffic, and capture highly detailed road information. This can then be turned around to inform the road project design, where corrections to asphalt mat can be made beneath the surface.

Features of the Smooth Ride Road Scanner:

- Provides RTK capabilities for full 3D machine control and grading

- Software profiles for common machine types like pavers, mills, dozers to simplify use

- Modular design allows use across different machine brands

- Captures project data that can be analyzed and used for "digital twin" simulations

- Designed for easy use by operators across experience levels

Topcon's new Smooth Ride Road ScannerBrandon Noel

Topcon's new Smooth Ride Road ScannerBrandon Noel

2:40 pm CST - 3/26/24

HAMM Is on a Roll

Tim Kowalksi shared details about the newly launched roller from the Wirtgen Group HAMM series that is loaded with all the latest technology the company has to offer.

(Left) Tim Kowalski, (center) Matt GravesBrandon Noel

(Left) Tim Kowalski, (center) Matt GravesBrandon Noel

Key features of the HAMM HD+ 120i VIO-2-HF roller:

- Dual bio drums with vibration and isolation capabilities on both the front and rear drums

- High-frequency roller drums for faster travel speeds while maintaining compaction impacts

- Ability to run dual oscillation or have one drum vibrate and the other isolate

- Auto switching feature where the front drum vibrates and the rear drum oscillates when moving forward for continuous compaction

- Updated bio-resonance technology in the drums to work better with modern asphalt mixes

- Versatility to potentially reduce the number of rollers needed on job sites due to different compaction settings

1:10 pm CST - 3/26/24

A Layer Deeper With the Crafco EZ Patcher

The new skid steer mastic applicator made its debut at PAVE/X, but the details were pretty scant, at the time. Now, the company is prepared to really show it off. Speaking with Tom Pfuelb, who worked on the lead team who developed the product, going back four or five years, says the big interest currently for this product is really the DOTs and public works sector who want to expand the mastic operations while meeting stringent safety standard.

Chantal Zimmermann

Chantal Zimmermann

Key features of the EZ Patcher product:

- Automates mastic application process for road repair

- Allows operator to apply mastic independently with a skid steer for improved speed and safety

- Removes manual labor from mastic application to reduce fatigue and improve production

- Enables one person operation for mastic patching jobs

- Provides better control and consistency in mastic application

- Nearly doubles production rates from mastic melting equipment

- Reduces labor costs for mastic jobs by approximately one third

11:40 am CST - 3/26/24

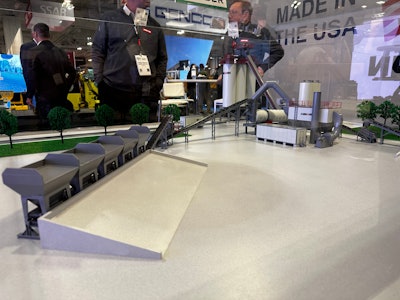

Ammann launches new ACC Alpine asphalt plant

Ammann is making moves in the industry, and wants to position itself to make headway in the market. To do that they're launching their European influenced asphalt plant capable of between 300 - 600 TPH. The FIRST plant of this design will be built in Cincinnati, OH, right in my backyard! Here's a picture of a physical scale model they had at the booth.

A scale model of the ACC Alpine.Brandon Noel

A scale model of the ACC Alpine.Brandon Noel

The Alpine series enables HMA producers to maximize high total production of recycled asphalt pavement (RAP) content without sacrificing mix quality, utilizing Ammann's industry-leading controls and technologies. The Alpine series control system is intuitive and allows tracking and analyzing plant operating data in real time to provide opportunities to gain further efficiencies over competitive equipment.

The plants produce high-quality mix designs, including high recycled product (RAP) mix designs with typical rates of 50% standard and 60% via dual collar feed. The extended mix section of the drum allows for better heat transfer to the material and longer mixing time. The 60% RAP capabilities give the Alpine market leading RAP content at a high consistent quality. The Alpine series plants core components are also capable of seamless integration into an existing asphalt facilities for retrofit and upgrade needs.

10:30 am CST - 3/26/24

Wirtgen Brings Large Milling Tech To Smaller Lineup

Info on the Wirtgen W 150 Fi from the milling guru Tom Chastain.

9:27 am CST - 3/26/24

Cold Colored Asphalt

The Colorbiotics soybean-based bio-additives and other asphalt solutions have been around for years, and they've continued to gain acceptance and adoption in the industry. Their combination of performance and environmentally friendly products is what drives them to keep iterating. I sat down with the president and its head of products for a longer conversation about the company's place in the contractor's toolbox, but the coolest thing I saw at their booth was the colored asphalt.

EasyPave plus Invigorate, with an added pigmentation.Brandon Noel

EasyPave plus Invigorate, with an added pigmentation.Brandon Noel

The product is a variation of the company's East Pave plus its Invigorate rejuvenator. It's made from 100% RAP, and the color-pigmentation is not a surface-level treatment but is throughout the entire mix. This means, as it wears over time, it will still retain the same coloration evenly. The company says the product is not recommended for public roadways or commercial applications like parking lots. It's best designed for private pathways, walking, farming lots, or golf carts.

8:44 am CST - 3/26/24

Early Bird Visit With Eagle Crusher

This machine is a perfect addition for asphalt producers utilizing a portable plant system. It offers some of the high-end crushing and screening capabilities for Recycled Asphalt Pavement, but with the flexibility of being fully mobile.

Eagle Crusher's MAXRap25 PortableBrandon Noel

Eagle Crusher's MAXRap25 PortableBrandon Noel

Hydraulically actuated diverter chutework allows multi-feature deck selection, blending and by pass. Calibration chute for sampling verifies that the mix-design spec requirement is correct. Screen service platforms are positioned on both sides of the screens for ease of maintenance. Available side-discharge conveyor from crusher may be used for stockpiling or returned to another conveyor for re-circulating back to the plant screen for resizing. Ability to utilize system for screening only, all material is conveyed to stockpile. Under screen product conveyor to cross conveyor feeds to the drum mix feed conveyor for final processing and mixing. Features the industry's first LIFETIME ROTOR WARRANTY on its solid-steel, three-bar, sculptured rotor-the industry's heaviest-to keep you up and crushing.

DAY 1:

6:30 pm CST - 3/25/24

All Aboard With Dynapac On The Steam Boat "General Jackson"

There were many first night industry events for those attending World of Asphalt 2024, but, as I am only one person -- I could only attend one event. It just so happened that this event was on a steam boat floating down the river. Once you were on, there was no getting off, and, in retrospect, it's a pretty genius way to keep party hoppers to stay put.

Aboard the steam boat General Jackson for the Dynapac party.Brandon Noel

Aboard the steam boat General Jackson for the Dynapac party.Brandon Noel

However, even if you could have hopped parties, you probably wouldn't have wanted to, as the food, drinks, and the live music were all incredible. It was a great end to the first day of WOA, and, as I am writing this at 1:32 am CST, knowing I have to get up and do this all again tomorrow (already today), I have to get some shut-eye! Thanks for following along today, and we hope you check back in during all the events tomorrow.

5:00 pm CST - 3/25/24

Day One Came Out Swinging!

Brandon Noel

Brandon Noel

The end of Day One at Music City Center in Nashville, Tenn. So much more to come tomorrow! Be sure to keep checking back here during the after hours as we attend the Dynapac customer appreciation party. Going out on a boat!

3:45 pm CST - 3/25/24

New product alert: Etnyre International's Scrub Seal Broom Box

Etnyre International showcasing its new product at World of AsphaltBrandon Noel

Etnyre International showcasing its new product at World of AsphaltBrandon Noel

Scrub Seal Boom BoxBrandon Noel

Scrub Seal Boom BoxBrandon Noel

Key Components:

- Hydraulically adjustable on the fly from widths of 8 ft to 14 ft via wireless remote control

- Self-contained unit that mounts to any distributor with minimal modifications

- Quick-release broom heads for easy replacement

- High lift attachment for self-loading on trailer

- Box contains emulsion so no runoff against curbs or road edges

- Hinged to auto flex on crowned roads

- Less mess at the end of shots

- Box won't drift on sloped roads because it is firmly attached to the distributor

- Box can be left attached to the distributor when transporting short distances for reloading

- Broom quickly detaches from the distributor

- Utilizes poly head brooms for extended life

- Positive Height adjustment- skis - allows for broom down pressure adjustment - helps save broom cores

- Self-contained electric over hydraulic control system

- No axles for transportation

- Cordless Controller

- 3 variable broom types available for different surface conditions

- Box stands for storage / extends life of brooms between production days / and for transportation / prevents brooms from matting when not in use

2:30 pm CST - 3/25/224

Patching and Pavement Maintenance from LeeBoy

LeeBoy officially revealed their 4 ton asphalt hot box trailer at PAVE/X, and they continue their march into the asphalt patching space by showing off their very own plate compactor. The two items are sold separately, but the hot box comes standard with a winch system that enables you to lift the plate compactor onto the trailer for easy transportation and storage. One new aspect of the hot box that I learned about today was its unique "oven" heating system. Bill Wilkens, of LeeBoy, explained it to me as a radiant heating system built into 5 of the 6 surfaces in order to keep the asphalt from scorching or burning on the bottom side. It provides a more evenly distributed heat throughout the stored aggregate.

Plate compactor features:

- Honda GX engine for power and reliability

- Reversible design for easy maneuvering in both directions

- High vibration rate of approximately 5000 vibrations per minute

- 3 year warranty from the manufacturer

Brandon Noel

Brandon Noel

HB4T Hot box features:

- Evenly distributed heat like an oven from all sides except the lid

- Insulated lid to retain heat

- Longer tank design to accommodate add-ons like infrared heaters

- Diesel burner system routes exhaust to heat all surfaces except lid

Brandon Noel

Brandon Noel

1:40 pm CST - 3/25/24

Trimble's Roadworks: Fix It With The Milling

Trimble recently released its roadworks 3D platform for cold planers and milling machines. I stopped by their booth to talk with Kevin Garcia about how the data can be used to improve road design, and deliver on projects in more accurate and consistent ways. He believes that mat smoothness and road ride-ability begins with what's underneath. Read the below excerpt of our conversation here, and to see the full conversation CLICK HERE.

Trimble

Trimble

FCP: Help me understand the qualitative or quantitative improvement this has over previous generations?

Kevin Garcia (Trimble): What roadworks does though, is it migrates to the to the newer platform, which is Android based. What's really cool about it as we're sitting here in this Trimble-slash-B2W booth is, you can be running B2W software and machine control software at the same time.

So if, for example, I'm standing on the mill, and one of my jobs is to track the number of trucks that are hauling the millings away, I can keep an idea of how many tons we've milled out. I'm using my machine control screen for now to manage that, that up-down-lleft-right of the mill, which I'm changing the profile or I'm optimizing the profile of the road for smoothness, material management, quality, QC type stuff. At the same time I could also just

FCP: How do they turn that 3D milling data into something actionable?

Garcia: I can start comparing my as-planned versus as-performed data. If it's not meeting standards, what happened? What changed? We know how many hours we were in the field, we know how much dirt we moved, and we know how much we paved. Why didn't it go according to plan? All the data is going to be there to teach you, you can start to hone in on what was that root cause, so that we don't do it again next time or that you bid accordingly so that it doesn't overrun.

It's also going to become a differentiator for certain levels of contractors. You can give the client a set of detailed information, so that if you ever decide to do a renovation later, it can tell you where the utilities are, it can tell you exactly how thick your asphalt is, it can tell you what the mix type was, in case you need to use that information later.

FCP: I think that the more that data is educational and actionable, I think that it's almost, it's as valuable as the tool on the day itself.

Garcia: I fully agree, I think you're gonna get to a world where the up-down-left-right of the machine is the commodity and the data of what we use will become invaluable.

To see the full conversation CLICK HERE.

11:10 am CST - 3/25/24

Dynapac Press Conference: Mental Health and SEISMIC Tech

The Dynapac press event covered two very important topics in the industry. One is asphalt compaction, and the other is in regards to proper mental health care for the workers of our industry. The president of Dynapac, Jamie Roush, has been an ardent and vocal supporter of the National Suicide Prevention awareness campaign. This morning he invited the head of Ajax Paving Industries, Vince Hafeli, to share his own personal story, as well as, the way his company is taking the matter seriously.

Vince Hafeli, president of Ajax (left), Jamie Roush, president of Dynapac (right).Brandon Noel

Vince Hafeli, president of Ajax (left), Jamie Roush, president of Dynapac (right).Brandon Noel

The two stood in front of the custom wrapped paving train from Ajax, sharing their goals for how the industry can improve conditions for those struggling with suicidal ideation, as well as, other difficulties with mental health. For more information you can visit www.vincehafeli.com and join the campaign too.

On the other side of the Dynapac booth, Eric Booth, the products manager for compaction, gave a short presentation about the new SEISMIC for asphalt feature that now comes standard on the models 2200 - 6200. The technology has been available for dirt and earthworks compaction for a few years, and has, in some cases, reduced the number of passes for adequate compaction as high as 20%, and while the data for asphalt compaction is not yet available in that regard, it does have a myriad of other benefits.

The technology has been available for dirt and earthworks compaction for a few years, and has, in some cases, reduced the number of passes for adequate compaction as high as 20%, and while the data for asphalt compaction is not yet available in that regard, it does have a myriad of other benefits.Brandon Noel

The technology has been available for dirt and earthworks compaction for a few years, and has, in some cases, reduced the number of passes for adequate compaction as high as 20%, and while the data for asphalt compaction is not yet available in that regard, it does have a myriad of other benefits.Brandon Noel

SEISMIC uses special sensors to harmonize the vibration in the rollers to match the frequency as it strikes the asphalt to maximize the momentum without wasting energy. As Booth put it, "Think of it like pushing your child on a swing. You don't give them a push halfway back, you wait till the peak of their back swing, just as they begin the way back down. The SEISMIC technology essentially does the same with vibration, maximizing the power, reducing emissions, improving ride quality, and making things more efficient."

At the Dynapac booth, Eric Booth, the products manager for compaction, gave a short presentation about the new SEISMIC for asphalt feature that now comes standard on the models 2200 - 6200.Brandon Noel

At the Dynapac booth, Eric Booth, the products manager for compaction, gave a short presentation about the new SEISMIC for asphalt feature that now comes standard on the models 2200 - 6200.Brandon Noel

For more details on the SEISMIC technology click here.

10:05 am CST - 3/25/24

Thunder Creek unveils New No-Hazmat Refueling Truck

Thunder Creek at World of AsphaltBrandon Noel

Thunder Creek at World of AsphaltBrandon Noel

The truck doesn’t require a CDL or a hazmat certification to operate. It gets around that because it takes the fuel limit of 119 gal in a single fuel container, and they built a truck with eight separate 115 gal tanks. The tanks can be individually selected, or they can be linked in any number of configurations. It is built on the popular IZUZ truck chassis that allows for high visibility and superior turning radius.

Brandon Noel

Brandon Noel

8:52 am CST - 3/25/24

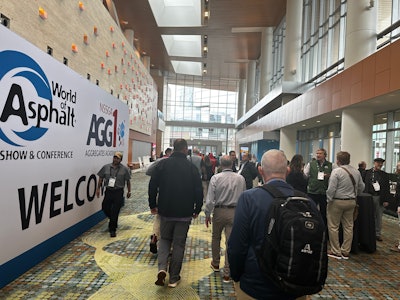

WORLD OF ASPHALT 2024 OPENS!

The heads of NAPA, AEM, AGG1, and several others all gathered to conduct a short ceremony signifying the official beginning to World of Asphalt 2024. The hall was already crowded with hundreds of attendees going to educational sessions and lining up to get their badges.

With the heads of NAPA present, the director of World of Asphalt and the president of AGG1 gave a short speech opening the showroom floor and cutting the ribbon to signify the official start of WOA 2024.Brandon Noel

With the heads of NAPA present, the director of World of Asphalt and the president of AGG1 gave a short speech opening the showroom floor and cutting the ribbon to signify the official start of WOA 2024.Brandon Noel

8:30 am CST - 3/25/24

Things Are Heating Up!

To be honest, I wasn't sure how to get to the Music City Center from my hotel. Thankfully, two gentlemen wearing Wirtgen shirts were walking out the lobby and I just followed them. The show floor won't open up officially until 9 a.m. CST, but there are many classes and educational sessions already in full swing. Not to mention, all the exhibitor staff showing up for duty in their booths. If you're rolling out of bed in your hotel room a little hung-over, it's time to hurry over and get in line for your badge!

Brandon Noel

Brandon Noel

8:17 am CST - 3/25/24

The Early Bird

Just standing here at my booth this morning I met two awesome contractors, especially David McDaniel from CDM Holdings in New Boston, TX. He was carrying a cigar (and I love cigars), and, as is typical of cigar lovers everywhere, when i confessed I had neglected to bring any of my own, he happily handed me one! That's real brotherhood right there.