Only a few countries have key technologies in semiconductor microchips. Why are these technologies so difficult to access? Are there any opportunities for latecomers like Vietnam?

In the semiconductor industry, no single country can undertake all the work, from A to Z. This is a value and supply chain. Each country chooses to focus on a certain stage of the production chain based on its advantages.

Vietnam is known as a country with cheap labor cost and plentiful human resources. Many high tech firms have set up factories to assemble and package products in Vietnam.

If Vietnam can prepare its labor force well, it will be able to undertake chip designing as well. Vietnamese youth are brainy and win high prizes at international competitions.

The challenging thing in semiconductor industry development is that manufacturing depends heavily on modern technologies and machines. The investment rate for a factory that can manufacture 7nm microchips is about $15 billion. It will be costly to manufacture 2-3nm chips.

The other challenge is seeking markets. Supposing that Vietnam has enough money to build a plant to make 2-3 nm chips, who will order from Vietnam to manufacture the chips? 2-3 nm chips have to undergo a quality examination and they must meet very strict requirements to be able to sell.

In the 1980s, Vietnam tried to develop semiconductor with Z181 factory. And only after 50 years has Vietnam come back and is trying once more. Do you think 50 years is too long?

Vietnam had a semiconductor manufacturing factory tens of years ago, which put out very simple components and exported them.

And now we have come back. However, going slow or fast will still depend on continued investment in science and technology, and in R&D (research and development) to create new technologies.

Now, Vietnam has a good labor force suitable in age and background, but knowledge and skills still cannot satisfy all the requirements of the semiconductor industry. I think the state needs to design a strategy to support universities and research institutes to make heavier investments in training and research. There should be a reasonable mechanism to attract talents to the industry.

Which stages do you think Vietnamese businesses can undertake in the global semiconductor supply chain – designing, packaging or manufacturing?

The industry comprises many different stages, including designing, manufacturing, packaging and experimenting. If counting expansion, it would also include development of apps based on the manufactured microchips.

Of these segments, designing will bring highest profits, accounting for 52-55 percent of the production cost. No 2 belongs to manufacturing, about 24-25 percent, while the remaining goes to packaging and testing.

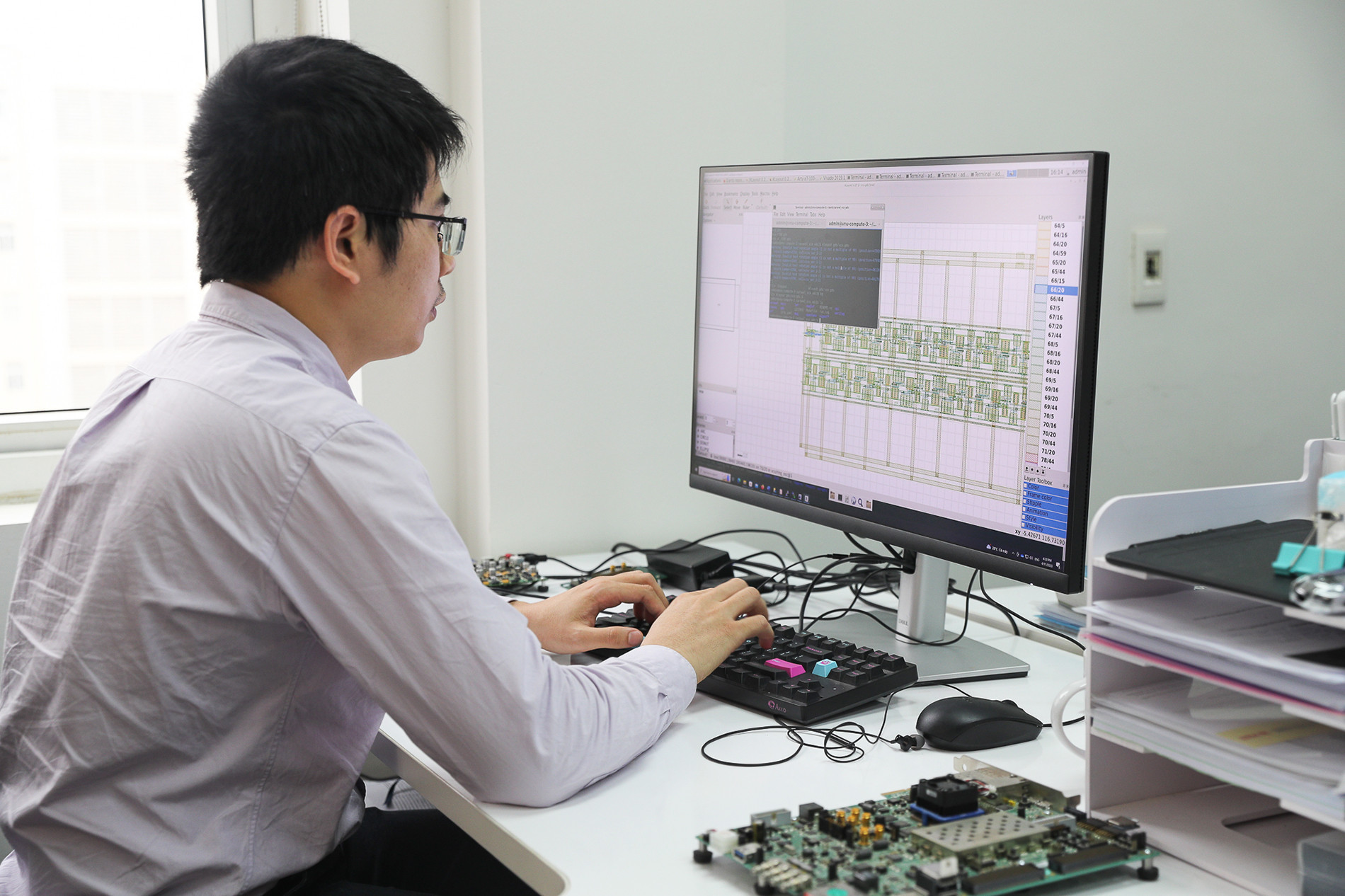

Currently, foreign invested enterprises (FIEs) in Vietnam focus on packaging and testing. In the long term, Vietnam needs to get involved more deeply in designing, which brings the highest value in the production chain.

Vietnam needs to prepare a workforce for designing by setting up startups, design centers and design firms. In the immediate time, Vietnam’s tech firms can design to orders by foreign clients, and later, can design the products of their own.

Regarding manufacturing technology, Vietnam should focus on mid-end technologies, 14-65 nm. These are products suitable to apps to be deployed in Vietnam. We are incapable of running after overly new and advanced technologies.

What does the state need to do to develop the semiconductor industry?

The Ministries of Information and Communications (MIC) and Science and Technology (MST) need to run specific programs to support microchip research and development. We need to define orientation and application of microchips to gather resources for AI chips, IoT chips, telecommunications chips, and chips for 5G and 6G.

As for the Ministry of Planning and Investment (MPI), the agency needs to make investment to develop laboratories set up at universities. The labs must come from cooperation between businesses and universities.

Once labs are located at universities, we can connect businesses’ operations with universities, and universities can approach enterprises’ questions. When students graduate from schools, they will be able to undertake work immediately.

What are your recommendations for young people and Vietnamese startups in the semiconductor industry?

For startups, the most important thing is seeking clients. Semiconductor is a field, not an occupation. Semiconductor industry comprises a lot of occupations which handle different apps and questions. Startups need to have specific advantages of their own to attract clients, develop markets, and grow.

PV