Nov 17 2017

A soft, flexible and stretchable microfiber sensor for real-time healthcare monitoring and diagnosis has been developed by a research team from National University of Singapore (NUS). The novel sensor is greatly sensitive and ultra-thin with a diameter of a strand of hair. It can be mass produced as it is cost-effective and simple.

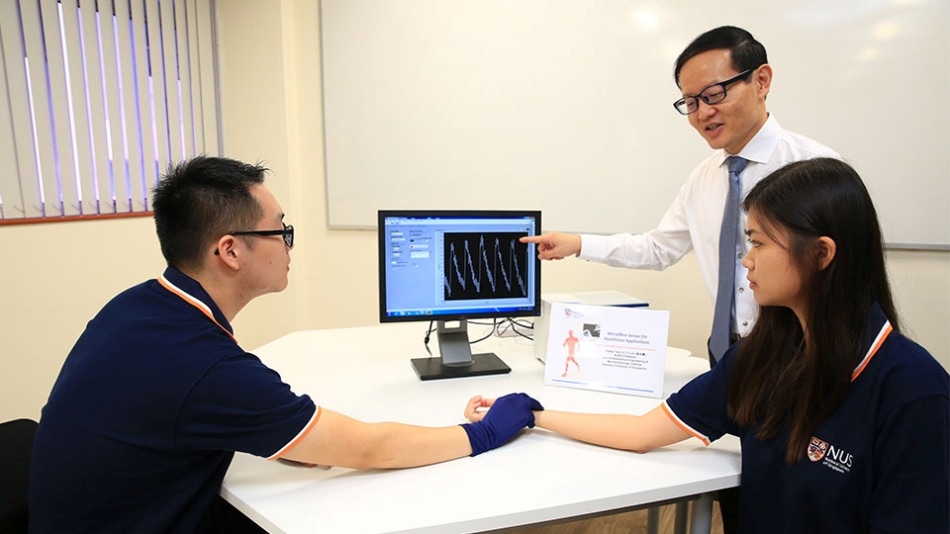

NUS Engineering researchers developed a novel microfibre sensor for real-time healthcare monitoring and diagnosis. The sensor can be woven into a glove to monitor heart rate and blood pressure. Credit: National University of Singapore

NUS Engineering researchers developed a novel microfibre sensor for real-time healthcare monitoring and diagnosis. The sensor can be woven into a glove to monitor heart rate and blood pressure. Credit: National University of Singapore

Wearable and flexible technology has gained major interest in recent years, resulting in tremendous progress in wearable and soft sensors. In tandem with this trend, microfluidic devices employing conductive liquid metals have been increasingly used as wearable pressure and strain sensors. However, existing devices have different limitations – for example, they may be uncomfortable to wear or may not fit well on the skin.

Our novel microfiber sensor can hardly be felt on the skin and conforms extremely well to skin curvatures. Despite being soft and tiny, the sensor is highly sensitive and it also has excellent electrical conductivity and mechanical deformability. We have applied the sensor for real-time monitoring of pulse waveform and bandage pressure. The results are very promising,

Professor Lim Chwee Teck, Department of Biomedical Engineering at NUS Faculty of Engineering, leader of the research team.

Real-time monitoring of pulse waveform

The smart microfibre sensor produced by the NUS Engineering team is made up of a liquid metallic alloy, which works as the sensing element, encapsulated inside a soft silicone microtube. The sensor is capable of measuring an individual’s pulse waveform in real-time, and the information can be employed for determining one’s blood pressure, heart rate and stiffness in blood vessels.

“Currently, doctors will monitor vital signs like heart rate and blood pressure when patients visit clinics. This requires multiple equipment such as heart rate and blood pressure monitors, which are often bulky and may not provide instantaneous feedback. As our sensor functions like a conductive thread, it can be easily woven into a glove which can be worn by doctors to track vital signs of patients in real-time. This approach offers convenience and saves time for healthcare workers, while patients can enjoy greater comfort,” added Prof Lim.

The microfiber sensor could also be helpful for patients suffering from atherosclerosis, which is the stiffening and thickening of the arteries caused by the buildup of fatty streaks. Over time, these streaks get accumulated into plaques which may totally block off blood flow or break apart, causing organ failure or may generate a stroke or heart attack.

Current methods of detecting plaque in blood vessels – such as computerized tomography scans and magnetic resonance imaging – would need bulky and expensive equipment. Such tests will have to be performed in hospitals by trained medical professionals.

As plaque will change the stiffness of the blood vessel and thus the pulse waveform, the novel sensor produced by the NUS Engineering team could be effortlessly used for detecting plaque before it accumulates to a size that is big enough to rupture or block the blood vessel.

Earlier this year, the NUS team published the development of the microfiber sensor and its usage for pulse monitoring in scientific journals Proceedings of the National Academy of Sciences (PNAS) and Advanced Materials Technologies, respectively.

Bandage pressure monitoring

In another clinical application, the smart microfiber sensor is applied the management of venous ulcers, which are developed by poor blood circulation. They take place when the veins in the legs fail to push blood back to the heart as well as they should. As blood pools in the veins, there is immense pressure in the veins, leading to progressive skin damage over time.

Compression therapy is considered to be a common treatment for venous ulcer. Based on the severity of the ulcers, bandages with different amount of pressure have to be applied on the legs of patients for months, which could also go up to even a year. If the bandage is very tight, it could lead to tissue damage, but if the bandage is very loose, the healing could be unsuccessful. Presently, healthcare workers tend to guess the pressure in the bandage at the point of application, based on experience and training.

As the pressure supplied by the bandage could change over time because of movements by the patient, continuous and accurate measurement of the bandage pressure in real-time is thus essential for guaranteeing that healing takes place in an effective manner.

Being highly flexible and ultra-thin, the NUS Engineering team’s microfiber sensor can be effortlessly woven into bandages in order to monitor the pressure that is being delivered and then maintained. This could potentially enhance the efficiency of the treatment and also reduce the time needed for healing. In future, patients will also be able to track the bandage pressure using an app, and the information could be shared with doctors capable of remotely monitoring the progress of the treatment.

The team is presently collaborating with the Singapore General Hospital to test the application of the microfiber sensor for bandage pressure monitoring.

Commercialization and further research

Our microfiber sensor is highly versatile, and could potentially be used for a wide range of applications, including healthcare monitoring, smart medical prosthetic devices and artificial skins. Uniquely designed to be durable and washable, our novel invention is highly attractive for promising applications in the emerging field of wearable electronics.

Professor Lim Chwee Teck, Department of Biomedical Engineering at NUS Faculty of Engineering, leader of the research team.

The team has now filed a patent for its smart microfiber sensor. Researchers are presently refining the sensor design and decreasing the size of its accessory in order to improve the user-friendliness of the device. The NUS team recently won the Most Innovative Award at the Engineering Medical Innovation Global Competition held in Taipei in September 2017.

While the NUS researchers are still to explore new applications of the microfiber sensor, they are also keen to work with commercial partners in order to bring their novel sensor to market.