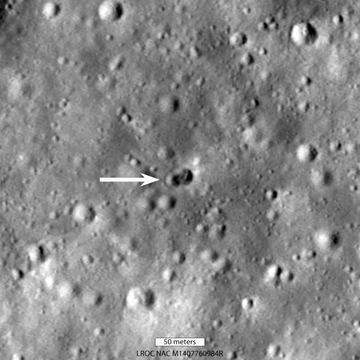

For taxi testing on Oct. 31, 2014 at NASA's Armstrong Flight Research Center at Edwards Air Force Base, in California, the Adaptive Compliant Trailing Edge (ACTE) flap was extended to 20 degrees deflection. Flight results will validate whether the seamless design with its advanced lightweight materials can reduce wing structural weight, improve fuel economy and efficiency, and reduce environmental impacts. (Photo Credit: NASA/Ken Ulbrich)

The future of flight may be seen in NASA's new shape changing wings, made in collaboration with FlexSys. They're leaner, greener, and may cut down on noise pollution, too.

Instead of the familiar aluminum flaps, these plane wings use a proprietary, unibody design called FlexFoil that can be retrofitted to existing aircraft. You can see the technology here on a modified Gulfstream III.

Traditional flaps on airplanes pivot up and down to control lift and drag, but their range of motion is limited. In addition, gaps open as they pivot that make for a noisier flight experience. With a seamless, transforming flap, this new wing can adapt to new conditions more fluidly, and fill in the gaps to reduce noise and wasted fuel.

This design makes the wings lighter, more adaptable, and more efficient than existing wings, which is a goal of the Environmentally Responsible Aviation program. FlexFoil has already passed wind tunnel tests, and test flights are getting under way to see whether the wings are sky-ready. Once the test flights are finished, greener skies are in reach for the aviation industry—with a little boost from NASA.

Via NASA