WACKER Expands Silicone Elastomer Production in China

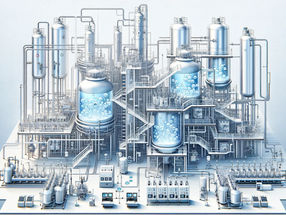

WACKER inaugurated a new production line for silicone elastomers at its Zhangjiagang site in China. With an annual capacity of several thousand metric tons, the facility will help support WACKER’s future growth path in China and improve the availability of high consistency silicone rubber (HCR) in the Asia-Pacific region. The plant’s cutting-edge equipment includes world-class kneaders which are essential for manufacturing high quality HCR grades. The expansion measure – a lower double digit million investment – underscores WACKER’s commitment and technological leadership in the silicone rubber industry.

“Today’s event not only is another milestone in WACKER’s efforts to expand its operational footprint in China, but also shows our determination to further serve and develop local and regional markets,” said Paul Lindblad, President of WACKER Greater China, at the inauguration ceremony. The expansion of WACKER’s silicone elastomer plant is yet another example of the company’s ongoing investments into its Chinese facilities. “The new manufacturing line will contribute significantly to our silicone rubber production capacity. This will enable us to improve our service to customers and business partners, who are willing to grasp the opportunities in today’s ever-changing and increasingly sophisticated marketplace”, Lindblad said.

Christian Gimber, Vice President of Engineering Silicones, emphasized the growing need for silicone specialties and high quality silicone rubber. “High consistency rubbers are widely used, and we expect them to continue on their growth path,” he said. Over the last decades, the demand for solid silicone elastomers has grown quickly, especially in China. “Today, the country is the single largest market for silicone elastomers in the world.”

WACKER’s new production line is located in a new building complex covering 2,000 square meters. The facility’s kneaders are currently the largest of their kind in the industry. The plant’s mixing and screening equipment and the state-of-the-art waste treatment process are also setting industry standards in terms of productivity and sustainability. The new production line will enable shorter lead times, speed up market response, and improve overall customer experience.

Most read news

Other news from the department manufacturing

Get the chemical industry in your inbox

From now on, don't miss a thing: Our newsletter for the chemical industry, analytics, lab technology and process engineering brings you up to date every Tuesday and Thursday. The latest industry news, product highlights and innovations - compact and easy to understand in your inbox. Researched by us so you don't have to.