Tesla's business model depends on continuous improvements in the cost and energy density of batteries. When Tesla was founded in 2003, it was barely possible to build a battery-powered sports car with a six-figure price tag. Over the next 15 years, cheaper and more powerful batteries enabled Tesla to build roomier cars with longer ranges at lower prices.

Tesla expects that progress to continue—and maybe even accelerate—in the next few years. And it isn't waiting for other companies to come up with better battery designs. In recent years, Tesla has had a large team of engineers re-thinking every aspect of Tesla's batteries, from the chemistry inside the cells to the way the batteries are incorporated into vehicles.

At a much-touted Tuesday event, Tesla pulled back the curtain on a suite of improvements the company hopes to roll out in the next three years. In total, Tesla says that all of these innovations put together will enable a 56-percent reduction in the per-kWh cost of its batteries.

As a result, Elon Musk said, Tesla will be able to realize a longstanding dream: a truly affordable electric car.

"We're confident that long-term we can design and manufacture a compelling $25,000 electric vehicle," Musk said. He added that this would happen "probably about three years from now." Tesla didn't provide a name or other details about this planned low-cost Tesla.

This being Elon Musk, it's worth taking the timeline with a grain of salt. And as a forthcoming deep dive by Ars Technica's Scott Johnson explains, some of Tesla's supposed breakthroughs—especially with respect to cell chemistry—are worth viewing with skepticism.

While a 56-percent reduction in battery costs over three years might seem like a big improvement—and it would be—it would represent a pace of progress only modestly faster than what the broader battery industry has enjoyed in recent years. For example, research firm BloombergNEF estimates that the market price of a 1 kWh battery pack fell from $1,160 in 2010 to $153 in 2019. That represents a nearly eight-fold decline in nine years—or a halving of battery costs every three years.

Still, Tesla is perhaps uniquely well-positioned to capitalize on the falling cost of batteries. It has a strong brand and unmatched infrastructure—including its SuperCharger network—to make electric vehicles mainstream. So if Tesla can deliver on the innovations it unveiled on Tuesday, it will have a bright future.

Tesla’s secret weapon: Vertical integration

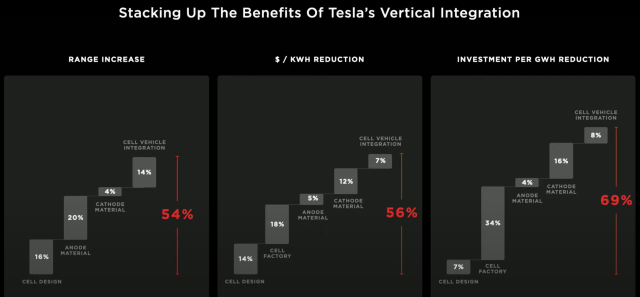

Tesla designs and builds more of its own parts than most car companies. As a result, Tesla can look for cost savings and performance improvements at every stage of its supply chain. It can optimize the smallest details of individual components as well as tinker with the overall design of a vehicle. And it can optimize components for the specific needs of its own products.

That attention to detail was evident in Tuesday's battery presentation. Tesla's projected 56-percent reduction in battery costs can't be attributed to any single technological breakthrough. Rather, it's the cumulative result of improvements in battery chemistry, cell design, cell manufacturing process, and the way batteries are incorporated into vehicles.

In the past, the bulk of Tesla's batteries were built around battery cells manufactured by Panasonic at the Gigafactory, the Nevada battery factory jointly developed by the two companies.

Tesla says that it plans to continue working with Panasonic and other cell suppliers, but it will need so many batteries in the coming years that the company will also start producing its own cells. Tesla estimates that it will produce 100GWh of its own cells in 2022 and a massive 3,000GWh by 2030. For comparison Tesla's website states that Tesla's main battery factory, the Gigafactory in Nevada, reached an annualized production rate of 20 GWh in mid-2018.

Tesla has ambitious plans for its new battery cells. They will use different battery chemistries, including one that eliminates the use of expensive cobalt in favor of nickel.

But Tesla also expects to reap double-digit cost savings from more prosaic improvements to its manufacturing process. Drew Baglino, Tesla's vice president for energy engineering, pointed to the bottling industry, where soft drink makers maximize throughput by keeping bottles constantly in motion, as a model.

"Together with our internal design team that makes this equipment and designs this equipment, we coupled thinking about how to make the best cell with thinking about how to make the best equipment so that we could accomplish the fastest parts-per-minute rates on all of these tools," said Baglino.

Baglino argued that vertical integration with the teams designing the machines is key to achieving higher throughput because "we don't have all these edge conditions between one piece of equipment and another. We can design the entire machine to be one machine and remove all these unnecessary steps." The result: a seven-fold improvement in cell manufacturing throughput.

Tabless cells and lithium mining

For example, in a cylindrical battery, the cathode and anode are wound tightly around one another. In a conventional battery, a "tab" sticks out of each side of this roll—one connecting the coiled cathode sheet to one end of the cell, the other connecting the anode to the opposite end. Tesla says it has pioneered a new "tabless" internal structure that is not only less prone to overheating, but is also easier to manufacture. Eliminating the tabs means there's less need to start and stop the manufacturing process to make sure the tabs are properly positioned in each coil.

Tesla says it is even planning to get into the mining business. Currently, lithium mining overwhelmingly occurs outside the United States. But Musk says that's not because there's a shortage of lithium in the US. Indeed, he argued, lithium is abundant around the world; there is enough lithium in the ground in Nevada alone to replace the entire US vehicle fleet with battery-electric cars. So Tesla is planning to start its own lithium mining operation in Nevada with a new, Tesla-developed mining process.

"We actually bought rights to a lithium clay deposit in Nevada—over 10,000 acres," Musk said. "The nature of the mining is very environmentally sensitive in that we take a chunk of dirt out of the ground, remove the lithium, and then put the chunk of dirt back where it was."

reader comments

479