The heart of NASA's Space Launch System arrived at Kennedy Space Center last April as the agency's first human-rated deep space rocket in 50 years.

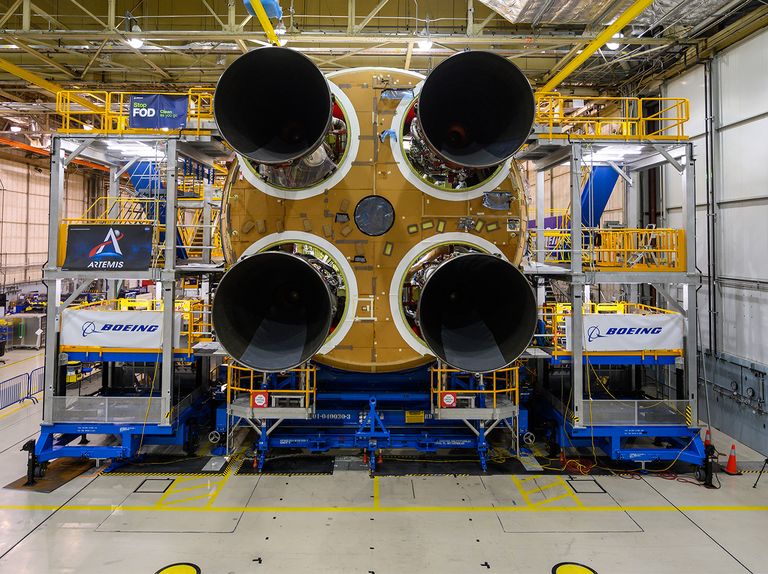

The 212-foot core stage rocket, along with a pair of solid rocket boosters, and the Orion crew module largely make up the Space Launch System (SLS), which NASA is counting on for its Artemis program’s 2026 return to the moon—a feat the agency last accomplished with Apollo 17 in 1972.

Despite the decades between manned lunar launches, the SLS relies on a workhorse from the shuttle program. Mounted at the bottom of the core stage are four RS-25 engines—formerly called the Space Shuttle Main Engine (SSME)—supplied by Aerojet Rocketdyne. Originally designed in the 1970s, the engines are seasoned, upgraded veterans, with 25 previous space shuttle flights among them. Among the four engines mounted to the SLS are numbers 2045 and 2060, both used on July 8, 2011, to launch the shuttle’s final mission, STS-135. Doug Bradley was at Kennedy Space Center during that launch, working as a chief engineer for Rocketdyne. “I’ve been to many flights, but it was different for 135,” Bradley says. “It was electric. It was a very emotional flight.”

The retirement of the space shuttle left Rocketdyne with a backlog of 16 engines, which the company mothballed. It was sad, says Bradley, to see them decommissioned when they could have flown dozens more missions.

Now with the title of Deputy Program Manager at Aerojet Rocketdyne, Bradley is overseeing the rebirth of the SSME engine. (A 2013 merger with Aerojet led to the company’s current name.) And it’s quite a comeback: SLS is the custom-built, off-planet ride for NASA’s Artemis campaign to return humans to the lunar surface and later to land people on Mars. That puts the SSME, originally created with slide rules and paper, at the foundation of 21st-century human exploration.

“It’s very gratifying to see those engines resurrected,” Bradley says. “And what’s better than going to the moon and Mars?”

Rocketdyne began production of the SSME on March 31, 1972, but it’d be another five years before Bradley would come on board. An engineering graduate fresh from California Polytechnic State University in San Luis Obispo, Bradley got a tip from a neighbor and applied at Rocketdyne to work on the shuttle program.

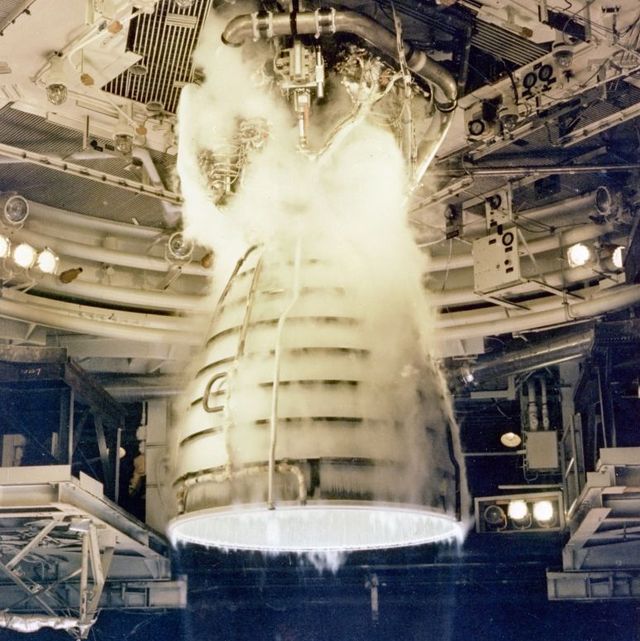

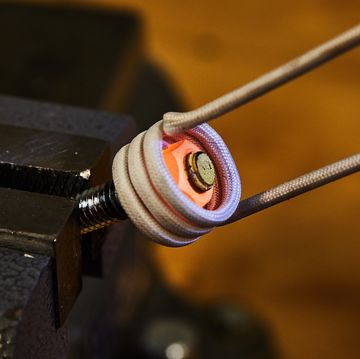

“I was old-school. Every design you were getting down on a physical drawing board with pens or pencils,” Bradley says. “They started hot-fire testing engines in 1975, but in ’77 we were still burning up a fair amount of engines. I was in turbo machinery and we were taking the brunt of some of the damage, so it was very exciting.” Four turbopumps are at the fiery heart of the engine’s design. These spinning, whirling fans create the extreme pressure that carefully shoots liquid hydrogen (LH2) and liquid oxygen (LOX) to the main combustion chamber. These machines operate in brutal conditions, with heat as high as 6,000°F inside the chamber—hot enough to melt an iron bar into a puddle. But it’s the temperature swings that introduce especially dangerous stress to the engine’s delicately machined innards.

“Just on the turbopumps alone, you’ve got a couple of thousand degrees gradient from one end of it to the other,” Bradley says. “The combustion chamber is even worse. They’re at thousands of degrees with (physical) tolerances of fractions of inches.”

Making central air conditioning for the main combustion chamber required some novel thinking. In the early 1970s, Rocketdyne researchers created a new copper-zirconium alloy called NARloy-Z expressly for use on the engine. The new material could withstand pressure and temperatures that threatened to deform the tiny channels that deliver superchilled liquid hydrogen through the main combustion chamber’s lining to keep it from burning up.

The SSME was also subject to years of testing conducted in an era before computer simulations. NASA dictated that the engines endure at least 65,000 seconds of flame and smoke on stands before making the first flight, even though the engine works for just 510 seconds during a mission. The trials included challenging the SSME to perform at power levels greater than what the mission required. Decades later, when NASA was evaluating SLS engines, that extra thrust would prove invaluable.

The space shuttle launched on April 12, 1981, becoming the world’s first reusable crewed spacecraft, and SSME the first reusable space rocket engine. When the orbiter landed, its SSMEs were removed, inspected, and refurbished before being readied for another mission.

“I call these my children because I’ve lived with all these engines from the day they were born, when they were tested, when they were flown,” says Bill Muddle, Aerojet Rocketdyne’s RS-25 field integration engineer, who also worked on the shuttle program. “I got to touch and be part of all of those motors through their history for 125 flights.”

It turns out that the reusable engines, built to the same standards, developed what engineers call “personalities” based on their performance and maintenance demands. It’s a phenomenon seen in airplane hangars and shipyards—places where hardware is reused and the maintainers get to know it during a service life.

And Muddle sees the existing stable of RS-25s in a similar, more personal way.

“I’ve got 16 unique children,” he remarks. “I love them all to death, but they all have their idiosyncrasies.”

As the shuttle missions changed, the engine was asked to run at higher levels, up to 104.5 percent of its rated power, mostly to handle greater weight for the International Space Station construction.

“They asked it to run at those high pressures and temperatures, and it came back every single time,” Muddle ways. “When you started that engine to put astronauts into space, it did.”

When the shuttle retired in 2011, so did the SSME, it seemed.

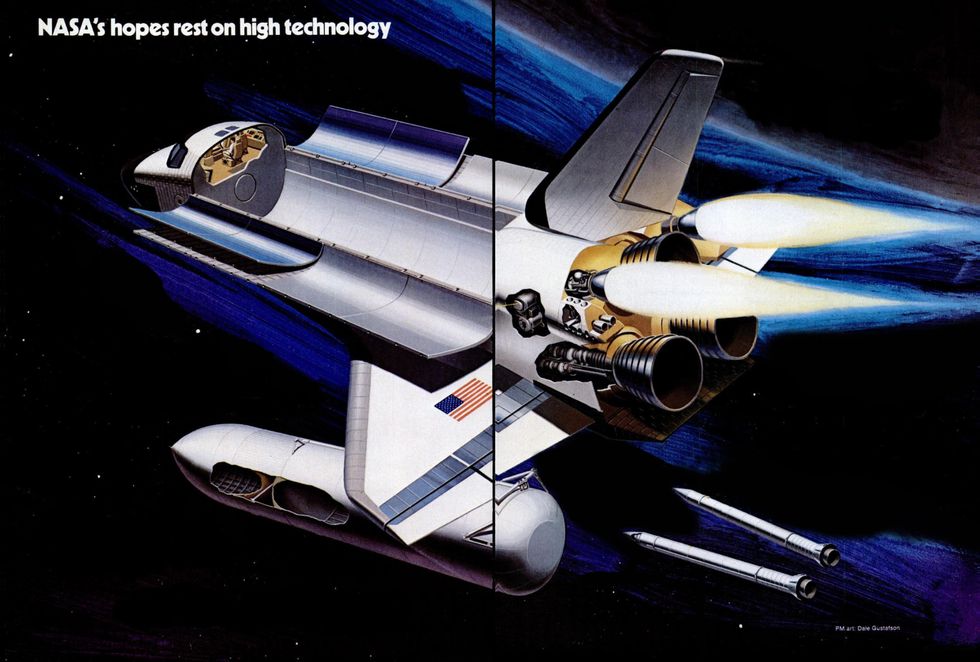

A Deeper Dive Into a Historic Spacecraft

Popular Mechanics met the new Space Shuttle in the months leading up to its inaugural launch in the April 1981 issue. Here's everything we knew about the metal beast—and its 3 RS-25 engines—back then.

In 2015, NASA prepared to announce its choice of engines that would be used in its new Space Launch System. With a 30-year track record and more than 1 million seconds of total ground test and flight firing time, the venerable engine’s history became a selling point, especially in a traditionally risk-averse NASA program. SLS will be the largest operational launch system ever built, and efficient engines get more benefits as rockets scale up, which was good news for the SSME’s bid.

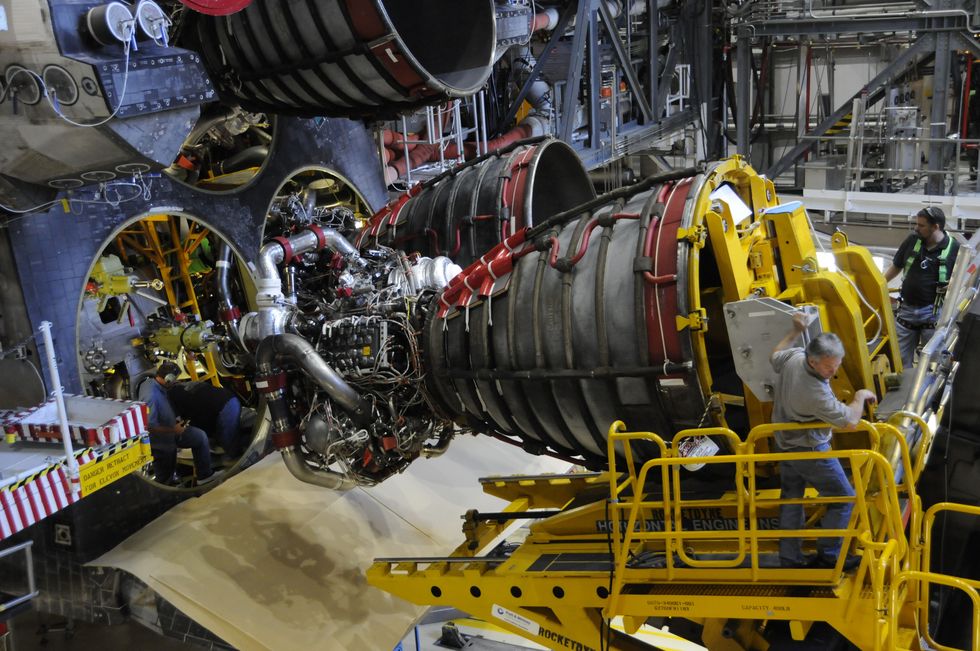

“We measure efficiency in specific impulse (ISP), like gas mileage for a rocket. Our ISP gets 452 seconds, which is very, very hot. For other rockets, that will be in the 300s,” Bradley says. “The more efficient you are, the less propellant you have to lift. Efficiency means, in reality, cargo.” That’s crucial, he added, for the Artemis program, which aims to establish a sustainable human presence on the moon and make crewed missions to Mars. In November 2015, NASA awarded Aerojet Rocketdyne $1.16 billion to adapt the 16 mothballed SSMEs to the new launch system and restart the production line for six new engines, now renamed the RS-25. “You hear that decision, you celebrate for 10 minutes, and then you get to work,” says Bradley. “It’s a different vehicle, so we got a lot to do. The rocket’s taller, so the pressure coming into the engines is higher when it’s started.”

The space shuttles used three SSMEs, but the behemoth SLS demands four engines, which further changes the operating environment. There isn’t much room to spare under the megarocket, especially given that people need room to work on them. “There’s only 8 inches between the wall of that vehicle and the edge of the engine,” Muddle says. “And I’ve got to put a technician in there that has to torque something.”

The nearby flames from the motors of 17-story solid rocket boosters, one affixed to each side of the core stage, also now pose a threat. “In the shuttle program, our engines were 20 or 30 feet higher than the boosters,” Bradley says. “On this rocket, we’re adjacent to them, and those are big, powerful beasts.” Extra thermal shielding now protects the four core engines from the two boosters.

During initial Artemis SLS launches, RS-25 engines will have to run at the maximum the SSMEs were designed for, 109 percent of the space shuttle’s main engine power.

Starting with fifth Artemis mission, the engines will be called on to reach 111 percent of the shuttle-era output. “Without any redesign per se, we can go ahead and throttle up a little bit higher. And we think we can go higher than that,” Bradley says.

The enduring use of this engine speaks to the strength of its original design, says Muddle. “You ask something to throttle up to 111 percent, 114 percent, and then also be able to throttle down to 65 percent, that’s a huge range to ask a rocket engine to do.”

NASA doubled down on the RS-25 in May 2020, when it awarded Aerojet Rocketdyne $1.79 billion to produce 18 more engines, on top of the six already on order. The combined price of this new RS-25 contract and the earlier one—resulting in a tab of possibly more than $100 million for each single-use SLS engine—has raised critical eyebrows.

After all, each SSME cost an estimated $40 million. And in 2018, United Launch Alliance paid Blue Origin an estimated $14 to $16 million per pair of its new BE-4 engines to use for ULA’s Vulcan Centaur rocket. The BE-4 produces similar thrust to the RS-25, but Blue Origin has not released its ISP.

Aerojet says a per-engine calculation is unfair, since the contract’s fee includes new hardware for additional testing, as well as investments in manufacturing that will generate overall savings. That’s still a lot of money for engines that will only be used once before being discarded into the ocean.

Dealing with an expendable launch system is new for the SSME veterans at Aerojet Rocketdyne, where the primary design and manufacturing ethos had changed from reuse to cost reduction. Company facilities in California and Florida are creating legacy engine components using 21st-century manufacturing techniques, like laser printing, to reduce the time needed to make and quality-check engines. “The main things we’re working on right now are retaining reliability and making it less expensive,” Bradley says.

The new RS-25s will only be fired during one test and one launch, so the engines won’t have the chance to develop those personalities that come from contact with maintainers.

The engine’s return on a one-and-done rocket makes for an emotional, bittersweet return. “I was sad to see my children go, but they’re going off to college now,” Muddle says.

On January 20, 2021, an RS-25 developmental engine fired for a full duration, the entire 500 seconds it takes to vault Orion into orbit. Bradley went to Stennis Spaceflight Center in Mississippi to work the test—familiar ground for the now high-ranking executive engineer.

The visit triggered memories of the first rocket engine test Bradley observed as a fresh Aerojet hire at the same location. He watched from the roof of a building just a quarter mile away from where the engine roared to life, assaulting his ears and spreading shock waves through his chest. “My thought at that time as a young engineer was: ‘How does that thing stay together?’” Bradley says. Watching the RS-25 flare to life in January 2021, thundering well past the original limits of its design, reignited those memories. “I’ve got to admit that during the last single engine test, I had the same thought,” he says. “I’ve been in this business for a long time, but the amount of power that we’re harnessing—I just never take it for granted.”

The SLS is scheduled to make its maiden voyage sometime this year, carrying an Orion capsule with an instrumented mannequin in the seat where astronauts will one day sit, and Bradley plans to see his old friend fly again.

“I’ll probably have a job to do,” Bradley says. “But I’m hoping I can sneak outside three minutes before the launch and watch it with my eyeballs.”

Joe Pappalardo is a contributing writer at Popular Mechanics and author of the new book, Spaceport Earth: The Reinvention of Spaceflight.