Members can download this article in PDF format.

What you'll learn:

- Comparing inductive and capacitive wireless power transfer.

- What is the EDEN wireless-power-transfer technology?

- Future plans for EDEN based on simulations and prototypes.

The wireless transfer of power for charging portable devices has become popular with device manufacturers and consumers. This is due, in part, to the convenience it offers and the fact it removes the need for billions of low-power chargers, many of which end their days in landfills.

Standards bodies such as the Wireless Power Consortium (WPC) boast hundreds of members and are making strides in developing standards that ensure interoperability within this sector. The popularity of this technology is illustrated in a recent report by research firm MarketsandMarkets, which estimates the market for wireless charging to currently be worth around US$5 billion, with a CAGR of almost 25%, reaching a value of around US$13.4 billion by 2026.

Challenges for Wireless Power Transfer

Standards such as Qi (pronounced “chee”) from the WPC are based on inductive technology using a magnetic field to transfer power between the transmitter (charger) and the receiver (device). This can be considered as a power solution, with the primary and secondary of the weakly coupled transformer split between the charger/receiver. Power transfer takes place when the two are placed in close proximity.

As wireless charging is all about user convenience, the “utopian” solution is to be able to place any device anywhere on a surface and have it charge—a feature known as “position freedom.” In fact, it would be even better if the surface were able to do more than charge and, in a perfect world, simultaneously power and charge devices and small appliances. Inductive charging doesn’t lend itself easily to such positional freedom, but an alternative—capacitive charging—offers significant potential in this area.

Though it’s the most widely deployed, engineers can consider a number of alternatives to inductive wireless power transfer (WPT). These include magnetic-resonant, RF, light, and ultrasound power transfer.

Magnetic-resonant transfer is based on energy being exchanged by creating a magnetic coupling between the transmitter and the receiver. This technology improves positional freedom but offers poor EMI performance, typically poor efficiency, and can be both complicated and expensive to scale to higher powers.

RF-based applications are often used in ‘far-field’ IoT applications, where they can transfer energy across greater distances. However, they generally can only support low power levels, and much like magnetic resonant systems, present challenges in terms of EMI and efficiency.

More exotic techniques that use light (lasers) or ultrasound work well for applications that require very low power levels, but they have poor efficiency and relatively cost more. These factors, as well as increased developmental risk, limit their viable deployment at higher powers.

And then there’s capacitive WPT.

Capacitive Wireless Power Transfer

While inductive charging transfers power by forming a transformer between the transmitter and the receiving device's embedded coils, capacitive power uses two metallic plates in the devices that are brought together to form a capacitor.

Compared to inductive WPT, capacitive WPT creates relatively directional electric fields, which reduces emissions and, therefore, the need for electromagnetic shielding. Also, because capacitive WPT systems are not ferrite-based, they can be operated at higher frequencies, allowing them to be smaller, thinner, and less expensive.

To overcome that problem, wide-bandgap (WBG) materials such as gallium nitride (GaN) and/or silicon carbide (SiC) are being used to develop a new generation of semiconductor switches. These devices exhibit reduced static and dynamic (switching) losses, thereby enabling higher-frequency operation with excellent efficiency that delivers successful capacitive WPT designs.

Capacitive Charging Proof of Concept: EDEN

Developed by the engineers at Eggtronic’s design center in Modena, Italy, EDEN is a proof of concept based on a new, patented capacitive WPT technology. EDEN is able to transfer power with total positional freedom, while addressing many of the challenges found with inductive or RF charging approaches.

Key to the EDEN concept is a thin transmission layer constructed from multiple low-cost capacitive transmission pads that can work independently of each other. The transmission layer (Fig. 1) consists of a flexible printed circuit board (PCB) that has multiple pads drawn upon the surface and a low-complexity IC integrated into each pad—a technology known as “chip-on-flex.”

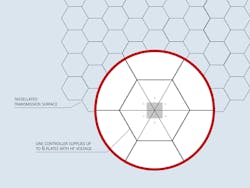

Measuring approximately 1 cm2, each cell is divided into six segments that allows a single controller IC to control the supply of high-frequency (HF) voltage. All of the control logic to command the cell activation and synchronization comes from the secondary side (receiver).

One benefit of this is that the silicon CMOS ICs on the transmitter cost less than US$0.20 per unit, as they’re just simple transmitters. Furthermore, the cost can drop dramatically when the technology goes into mass production.

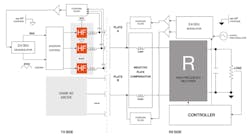

The system, based on a segmented charging mat (Fig. 2), operates at a very high fixed frequency (ISM 13.56 MHz). Most of the intelligence is embedded into the IC on the receiver side (Fig. 3).

The receiver, which has just two larger receiving plates tuned with the load, generates a 2.4-GHz signal thanks to an embedded modulator. This signal is used to enable the transmitter pads via capacitive coupling as the receiver is brought close to the charging surface.

Thus, the receiver can both initiate and regulate the power-transmission process by determining how many of the pads and segments are turned on. Based on the amount of power needed for the receiver to operate, the number of segments activated is able to change the natural frequency of the system, regulating the power transmitted to the load while ensuring fixed-frequency operation.

This system always operates in zero-voltage-switching (ZVS) mode, ensuring a flat efficiency curve. The first EDEN prototype is delivering efficiency in the 85% to 90% range, and improvements can be easily achieved in the next-generation prototypes.

Key Benefits

A significant advantage of the approach used to develop EDEN is the ability to charge or power multiple devices of diverse sizes simultaneously. With inductive charging, the size of the charging pad defines its most suitable devices. EDEN, on the other hand, can initiate pads based on the 2.4-GHz communication from the receiver. This means that the charging area can be sized to fit a wearable device or a television, or anything in between.

Capacitive WPT also offers many electromagnetic compatibility advantages, especially when using a fixed-frequency approach. Unlike the inductive approach, capacitive technology confines the electric field between the plates. And since the physical dimensions are completely unrelated to working wavelengths, dipole radiation is negligible. A quadripole plate design in the receiver eliminates any residual far-field radiation.

Furthermore, unlike inductive technique, there’s no foreign object detection (FOD). In inductive systems, FOD is a requirement—a metallic object (such as a coin) placed on the charging surface will receive power and heat up, possibly significantly.

With EDEN, a 2.4-GHz signal is required to initiate power transfer. Thus, metallic objects placed on the charging surface will shield the signal, preventing single cells from being activated when there’s a risk for heating metal, eliminating any possible issues.

Simulations and Prototypes

Much of the strength of the EDEN system lies in its simplicity as well as the ability to offer true position-free charging on a variety of surfaces, thanks to the extremely thin (<0.1 mm) transmitting and receiving pads. Unlike inductive charging, which doesn’t work with metallic chassis (this is one reason why most smartphones have glass backs), capacitive WPT is compatible with metallic and non-metallic devices.

During development of EDEN, Eggtronic performed extensive simulations. For example, powering a 15-in. laptop at a distance of 2 mm with a 290- × 200-mm receiver pad size provides 160 pF of capacitive coupling that delivers 100 W of power at an efficiency of 88%. Extrapolating the 100 W in 0.058 m2 indicates that EDEN has the potential to deliver around 1700 W/m2.

To further demonstrate the possibilities of the patented capacitive WPT, the company’s engineers built a prototype wireless television (Fig. 4). The technology was able to deliver position-free power to the flat-screen TV at an efficiency of 85%.

Looking to the Future

With a working prototype in place, the EDEN concept has been proved. The next steps involve integrating the transmitter and receiver design into dedicated ICs suited to mass production. Eggtronic’s long-term plan is to work with partners to embed EDEN in an ecosystem of devices ranging from TVs, laptops, and monitors to smartphones, tablets, and more.

The possibilities of this technology don’t end with wireless power transfer, though. Because the capacitive transfer is effectively a high-pass filter, the system can carry high-speed data, modulated onto the power signal.

As a result, it offers the potential to replace many types of cable, including HDMI and USB, allowing for secure data transfer between devices placed on the same charging mat. The prototype has demonstrated a capability of up to 150 Mb/s, although the next generation is expected to attain more than 10-Gb/s data rates.

The highly scalable nature of EDEN’s secondary brings further possibilities for the future. One that’s currently being contemplated is the ability to wirelessly charge vehicles. When the vehicle is stationary, the receiving plate would automatically lower and charging would begin.

Applications would include charging buses at stops along their route. With this ability to receive regular “top ups,” the traction battery capacity could be much lower, reducing cost, size, and weight and, therefore, extending distance per charge.

Summary

While much of the current wireless charging focus is on inductive technology, Eggtronic’s EDEN prototype demonstrates the many possible advantages to a capacitive approach for wireless power transfer. These include total positional freedom and the ability to charge or power multiple small and large devices simultaneously. The technology is extremely thin, scalable, and cost-effective, and can be used anywhere—including devices in metal cases.

The approach inherently offers low EMI, aided by the fixed-frequency operation, while the incorporation of ZVS operation into the secondary high-frequency rectifier ensures a flat efficiency curve.

Working prototypes have demonstrated the capabilities and viability of this technology. It holds much potential promise for the future, including data transfer via the charging mat and scalability that, in theory, would allow the charging of electric vehicles.