Results of a new industry survey were released by Essentium, and they show a very strong trend towards AM.

The survey, conducted for Essentium, asked manufacturers about their use of additive manufacturing technology in their operations. Essentium has performed similar surveys in the past, leading to the possibility of observing changes from year-to-year in the results.

This year the results show strong increased interest in additive approaches.

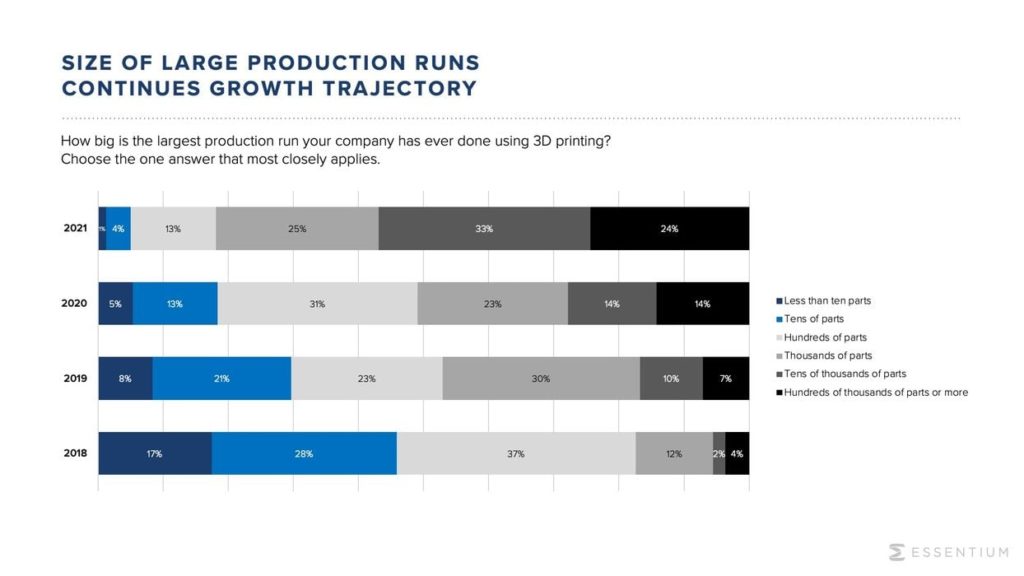

One of the most interesting statistics from the report is that since last year, the percentage of manufacturers using AM for “production runs of hundreds of thousands of parts” has increased from 14% to an astonishing 24%.

Think about that: one quarter of manufacturers are doing massive production runs on their fleets of 3D printers. That is a statement that could never have been made previously.

The survey also found that the percentage of companies making less than 10 parts using AM has decreased to a mere one percent, while that percentage was a healthy 17% only four years ago. It would appear that basically every manufacturer surveyed is doing additive manufacturing to some degree.

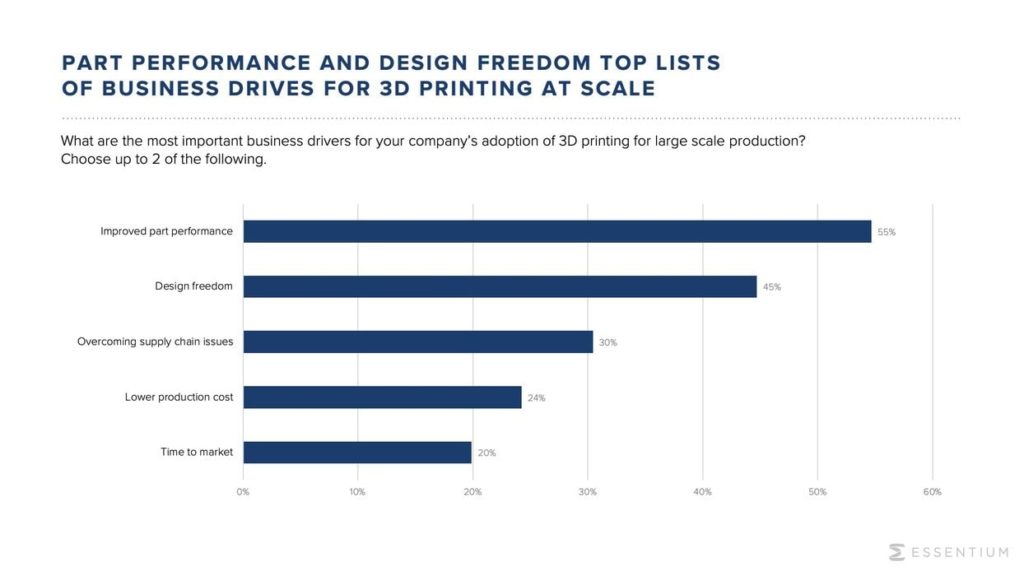

With such a large increase there must be reasons behind the shift. The answer to that question was also found in the survey, with four key points being raised by respondents. Let’s take a look at what they mean.

Improve Part Performance

I take this to mean “light weighting”, where a part is redesigned to incorporate lattice structures to reduce weight, and thus improve part performance. This is of particular interest to any industry involving moving powered vehicles, where weight consumes energy. The relentless surge toward energy efficiency is certainly driving this factor.

Increase Design Freedom

I’m very pleased to see this as the second factor, because it can mean only one thing: part designers have rapidly adopted DfAM techniques. 3D printing allows virtually no constraints in design, but for many years part designers simply did what they always do: design for the constraints of traditional manufacturing equipment. This finding suggests that an increasing number of designers have gone beyond traditional designs and now expect to be able to have complete design freedom. This is a major development.

Overcome Supply Chain Issues

Of course, this would be one of the drivers. Many manufacturers suddenly found their fragile supply chains completely broken with little hope for resumption. In desperation many turned to producing parts themselves, and one of the best ways to do so is with 3D printers. However, once exposed to the technology, these manufacturers have clearly become wise to additive manufacturing and are increasing their use of the technology.

Lower Production Costs

This is a very surprising finding. It suggests that manufacturers are finding the cost of producing parts using AM is lower than other approaches. In the past this has not been the case, and from a machine to machine comparison, typical mass manufacturing techniques are always less expensive than 3D printing.

However, it may be that the total cost of a part is being considered here. For example, with supply chains broken, the shipping costs for a part have dramatically increased. This added unit cost might tip the scale towards AM and financially enable more local production using 3D printers.

Other Findings

The survey also indicated that virtually all respondents believe the technology will save manufacturers “billions” in production costs as the tech improves. That’s a very favorable outlook, and shows intention to continue growing use of the technology.

Essentium CEO Blake Teipel said:

“Additive technology has matured to the point where manufacturers around the world can digitally print parts as they need them at speed, scale, and economics that challenge traditional methods. As AM is set to transform global manufacturing and enable more distributed and resilient value chains, we are working with our customers and partners to ensure they can reap the rewards of this new manufacturing era.”

I couldn’t agree more.

Via Essentium