Graphene may not be the wonder material which solves all the world’s problems but it has some compelling applications. It even has some claims to be a wonder material.

“As an electrical conductor at room temperature it is at least a factor of 10 better than silicon,” said Professor Simon Bending of Bath University, “its thermal conductivity is 100 times more than copper; its optical properties are pretty wacky too – a single atomic graphene layer absorbs a remarkable 2.3% of incident light over a broad range of wavelengths; and it is the strongest material ever tested – 40 times stronger than steel and even stronger than diamond – it can be stretched 25% and still stays intact.”

What’s more, according to Saverio Russo of Exeter University, GrapheXeter can be transparent – becoming more transparent the longer the wavelength of the light. It is also flexible, said Russo, and could be used to help with the scaling of resistive memory – providing memories that are dense, fast, flexible, transparent, bio-compatible, and robust with no end-of-life problems.

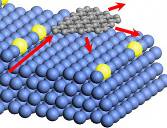

“Graphene is the only two-dimensional conducting membrane in nature,” said David Horsell from Exeter University, “it is optically transparent, strong, flexible, stretchable and impermeable.” No gas, not even helium, seeps through graphene.

Horsell is looking at sensors as being a rich area for graphene applications. Putting molecules of material on a graphene surface and measuring the effect demonstrates the extreme sensitivity of a graphene surface to other materials. “It can detect mechanically as well as thermally,” said Horsell, “we can use that to make a sensor.”

It can also be used in rapid DNA sequencing.

Steve Andrews of the University of Bath is working on photonics applications of graphene. “It’s very absorbing, its mobility is high, and its scattering time is low,” said Andrews, allowing the possibility of making metamaterials where you can tailor the optical properties.

Shaowa Zhang of the University of Exeter, is looking at graphene composites. Polymer-graphene, metal-graphene and ceramic-graphene. “its thermal conductivity, its light weight, its strength and its 2-D shape make graphene an ideal reinforcement to make stronger and tougher composites,” said Zhang.

Zhang proposed graphene-oxide e.g ZnO, SnO2, Co3O4, MnO2, or graphene-polymer, or graphene-CNT for supercapacitors, and Li-Ion batteries; graphene-TiO2 for solar cells and photocatalysts; and graphene-oxide for fuel cells.

Zhang reckoned graphene composites could be used for body/vehicle armour and in lightweight composites for aerospace and automotive applications – possibly replacing carbon fibres.

Alain Nogaret of the University of Bath has used graphene-polymer composites to make plastic oscillators which oscillate spontaneously when biased. “The composite codes mechanical strain into oscillation frequency – like mechanoreceptor neurons in the skin,” said Nogaret.

Nogaret thought applications for the work could be found in making sensitive skin for robots, for medical implants and catheters, and for skin drag reduction for aircraft.

Don Pantos of the University of Bath described the “unexpected structures” being formed by graphene’s properties of molecular self-assembly. “We’re trying to modify the surface of graphene,” he said, “we think we can understand donor-acceptor interaction.”

The Centre for Graphene Science has now got 44 researchers plus the same number again in post-docs and PhD students.

Now, says Prof Bending, is the moment for “strong engagement with the end-users of research.”

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News