Charles R. Goulding and Joseph Castine consider research into 3D printing to impact e-waste.

In this technologically dominated day and age, one of the largest sources of waste is e-waste including circuit boards, disk drives, batteries, and fluorescent lamps. These electronic waste objects contain some critical raw materials, such as gold, silver and cobalt, which could be reused in further iterations of these products.

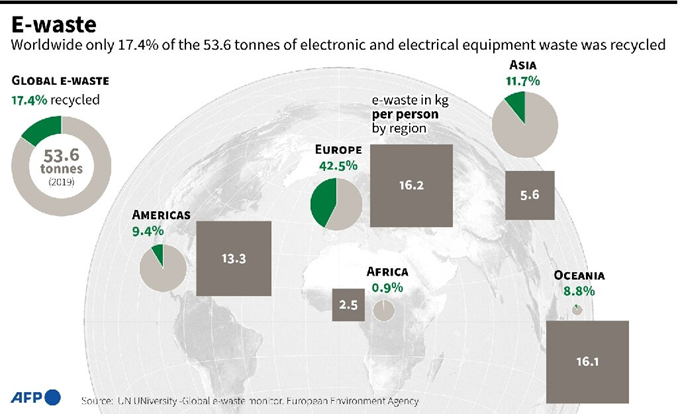

According to the UN, approximately 50 million metric tons of electronic waste were discarded in 2019, with a majority of this waste ending up in landfills. Converting these numbers into a percentage means that approximately 83% of electronics being discarded end up in landfills, representing more than $55 billion in wasted materials.

Federico Magalini, an author of the CEWASTE report, has said that even when some of these electronic products are recycled some of the raw materials are still not recovered. This presents a unique opportunity for the development of fully recyclable electronic components, an industry that scientists at Duke have begun to explore.

Engineers at Duke University have been exploring the opportunities for recyclable printed electronics. They have successfully developed the first fully recyclable printed electronics by producing transistors using their 3D printing technology.

These transistors made of three carbon-based inks were developed in hopes of inspiring a new trend in electronics that could help fight the global epidemic of e-waste. The team of engineers was able to develop these carbon-based inks utilizing crystalline nanocellulose from wood fibers as a dielectric, carbon nanotubes in place of semiconductors, and graphene as a conductor. Subsequently, the researchers were able to demonstrate that these inks could be printed using paper substrate by using an aerosol jet printer. Through testing of these transistors’ capabilities, they achieved on-currents of 87 μA/mm and a subthreshold swing of 132 mV/dec which can be applied in various alternate applications.

The recyclability of these devices was demonstrated by submerging them in a series of ultrasonic baths and then utilizing centrifuging technology. The resulting mixture showed recovery of over 95% efficiency, confirming that these recycled materials can be reused further for transistor printing.

Aaron Franklin, the Addy Professor of Electrical and Computer Engineering at Duke, said, “Nanocellulose is biodegradable and has been used in applications like packaging for years, And while people have long known about its potential applications as an insulator in electronics, nobody has figured out how to use it in a printable ink before. That’s one of the keys to making these fully recyclable devices functional.”

Nanocellulose has not only proved useful in packaging but also additive manufacturing. According to an article in Scientific Reports titled Shape fidelity and structure of 3D printed high consistency nanocellulose, the cellulose derivative has shown some promise with 3D printing techniques.

Although there are still some deformations with the material, continued research into these applications could prove beneficial as the substance is very abundant, and easily recycled. This new use of carbon-based nanocellulose in 3D printing of transistors may prove to be crucial in the move towards recyclable electronics. Using this newly developed aerosol jet printing with carbon-based ink has proven results with no compromises made to the structure of these transistors improving upon previous techniques with the material. With major tech firms including Dell, Microsoft, and Google joining initiatives to develop a circular electronic economy by 2030 these new transistor technologies may prove to be crucial in the propulsion of e-waste reduction.

The Research & Development Tax Credit

Whether it’s used for creating and testing prototypes or for final production, 3D printing is a great indicator that R&D Credit eligible activities are taking place. Companies implementing this technology at any point should consider taking advantage of R&D Tax Credits.

Enacted in 1981, the now permanent Federal Research and Development Tax Credit allows a credit that typically ranges from 4%-7% of eligible spending for new and improved products and processes. Qualified research must meet the following four criteria:

- Must be technological in nature

- Must be a component of the taxpayer’s business

- Must represent R&D in the experimental sense and generally includes all such costs related to the development or improvement of a product or process

- Must eliminate uncertainty through a process of experimentation that considers one or more alternatives

Eligible costs include US employee wages, cost of supplies consumed in the R&D process, cost of pre-production testing, US contract research expenses, and certain costs associated with developing a patent.

On December 18, 2015, President Obama signed the PATH Act, making the R&D Tax Credit permanent. Beginning in 2016, the R&D credit can be used to offset Alternative Minimum tax for companies with revenue below $50MM and, startup businesses can obtain up to $250,000 per year in payroll tax cash rebates.

Conclusion

With the development of these carbon-based inks and the process by which they can be used to 3D print transistors, it is likely that soon we may see these inks being used on a larger scale. With wider adoption of these technologies, it is foreseeable that the global epidemic of e-waste may begin to shrink as the global effort to produce more recyclable electronic components surges forward.