January 27, 2020 feature

A template for silk growth: Peptides bring control on many levels

Applications of silk fibers have ballooned in recent years. Traditionally attractive in textiles for its compact strength and luxurious soft sheen, silk has potential applications including filtration membranes and coatings to preserve foods, substrates for implantable electronics, and high-sensitivity biosensors. These technologies exploit not just the mechanical properties, but also the material's biocompatibility, biodegradability and intrinsic photonic properties, as well as the ability to dress the surface with optically active substances like quantum dots. No surprise, then, that scientists around the world have been hard at it to produce customized materials that exploit silk's multiple functional properties. Yet there remains a snag with silk-based biomaterials—getting the right material in scalable quantities. Now, researchers at MIT have demonstrated a way of templating the growth of silk that combines molecular control with scalable production.

"We basically define a new rule to 'grow' silk materials in ordered, hierarchical structures," explains Benedetto Marelli a professor at Massachusetts Institute of Technology in the U.S., who, alongside Ph.D. student Hui Sun, developed the approach.

The "hierarchical" organization of the molecules and structures at several length scales is key to many of the properties found in materials like silk or bone. The way the molecules assemble, the way the whole protein folds, as well as the structures subsequently formed, all affect the material's properties.

So far, the approach taken to produce silk materials has still closely resembled traditional methods. Some involve producing a suspension of the silk proteins, which is spun, cast, printed or subjected to solid-gel-solid phase transitions to form fibers, films or blocks. Alternatively, the silk fibers are stripped into nanofibrils, for instance, by using harsh solvents or ultrasonic dispersion. This kind of fabrication is fairly commonplace and low-cost, but offers little control over the microstructures.

"Research has mostly been limited to applying environmental triggers such as acidification, organic solvents and shear force during the assembly process with the aim of influencing the microstructures that form during the fabrication of fibers and films," says Sun. However, she adds that this still allows very little control over how the proteins fold and the molecular assembly that both critically determine the end material's properties. Researchers have demonstrated control at this level only with certain cloned "recombinant" proteins or protein-DNA hybrids. However, using this kind of building block is fiddly and not suitable for large-scale manufacturing.

Seeding a new approach

With a view to finding new ways to manufacture silk fibroin, the structural protein within silk fibers responsible for their mechanical properties and integrity, Marelli was looking back over previous work on biomineralization and silk fibroin when it occurred to him to combine the two approaches. "Our hypothesis was that by providing a peptide already in an ordered structure, we might be able to direct the folding and assembly of silk around this peptide," he tells Phys.org. "Using 'seeds' to control synthetic polymer formation is well established, which helped me in refining the idea."

To find useful peptide seeds, Marelli and Sun identified a number of requirements, which directed their attention toward GAGSGAGAGSGA, a dodecapeptide that stems from the highly repetitive hydrophobic domains found in a large subunit of the silk fibroin. GAGSGAGAGSGA forms nanowhisker-like structures of highly ordered β sheet molecular conformations. As well as exhibiting a well-defined morphology, the peptides are short enough that using industrial chemical processes gives acceptable yields without resorting to synthetic biology methods.

Marelli and Sun found that in water-based conditions, at room temperature and atmospheric pressure, GAGSGAGAGSGA nanowhiskers templated the unordered silk fibroin to fold into β strands and grow into β-sheeted nanofibrils. In addition, by adjusting the concentration of the peptide seeds and silk fibroin, and the molecular weight of the silk fibroin and pH, they could glean clues as to the mechanism behind the templated growth and further fine-tune the process.

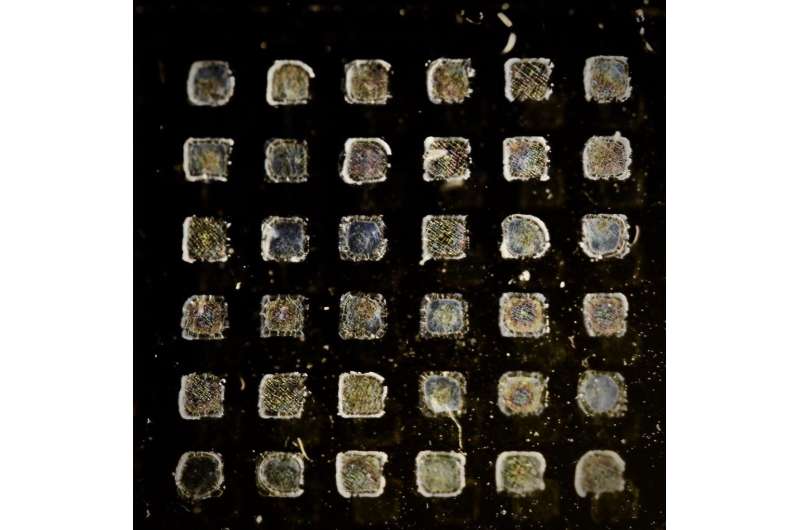

Next, the researchers demonstrated templated growth with an alternative peptide found in the silk protein of the European honeybee, which forms less regularly defined nanoassemblies of a combination of β-sheet and α-helix conformations. They observed the impact on intermolecular arrangement, and hence, the mechanical and optical properties of the resulting materials by seeding with the different peptides. They were also able to demonstrate the applicability of nanofabrication techniques to deposit layers of templated silk materials and to print suspensions of the seeded fibroins into custom structures.

A template for future work

Among the potential applications Marelli lists: printable pathogen sensors with properties that can be used to detect when food spoils with enhanced sensitivity as a result of the increased surface to volume ratios, compartmentalized devices that encapsulate enzymes for enhanced catalytic responses, filtration membranes for selective mass transport, complex surface functionalization with contrast surface chemistry, site-specifically crystallized silk films with programmed degradation capability, and information storage and encryption.

Marelli and Sun are now using architectures found in biological tissues such as butterfly wings, bones and tendons as a source of inspiration for future studies. "In the case of tendon, this is a tissue made of hierarchically structured type I collagen molecules that are organized across several scales from molecular to centimeter," Marelli explains, highlighting how this can impart a particularly wide range of functions in a single material format, including enhanced mechanical properties.

Replicating the hierarchical structures found in butterfly wings may also lead to useful materials for antifouling and enhanced heat dissipation. "It is difficult to reproduce these architectures with current nanofabrication techniques based on bottom-up (i.e., assembly) approaches," he adds. "Our future interests will then be in using templated crystallization to enable the fabrication of mesostructured materials with such properties."

Full details are reported in Nature Communications

More information: Hui Sun et al. Polypeptide templating for designer hierarchical materials, Nature Communications (2020). DOI: 10.1038/s41467-019-14257-0

Journal information: Nature Communications

© 2020 Science X Network