Capturing carbon emissions before they enter the atmosphere is a white whale for the fossil fuel industry.

In theory, if a power plant or a factory could easily eliminate carbon emissions by filtering them out of flue gas, the plant would be able to pursue business as usual with some simple retrofits—no threat of future regulations mandating lower emissions, no push to switch to completely new technologies.

The problem is that carbon capture is energy-intensive and expensive, it doesn't capture all the carbon dioxide being released, and it's not always clear what to do with the gas after it's captured. (The current best option is to find underground caverns in which the carbon can be stored, or sell the CO2 to older oil fields for enhanced oil recovery.)

While politicians and industry leaders like the idea of carbon capture, it has failed to get off the ground because of these problems. Currently, North America only has two commercial coal-fired power plants using carbon capture: one in Saskatchewan at the Boundary Dam 3 unit and the other at the Petra Nova facility in Houston, Texas. A plant in Mississippi had plans to use lignite coal to make synthetic gas and capture carbon emissions from that process, but the Kemper plant's owner announced in 2017 that it was more cost-effective just to use natural gas and abandon the synthetic gas and carbon capture technology.

Could new technology save carbon capture?

Recently, researchers from Oak Ridge National Laboratory published a paper in the journal Chem, detailing a new sorbent (a solution of molecules to which CO2 binds) that could reduce the energy needed to filter carbon dioxide from flue gas.

The Oak Ridge team says that this carbon-capture method uses 24 percent less energy than a benchmark carbon-capture industrial sorbent called monoethanolamine (MEA).

Reducing the amount of energy that carbon capture requires is critical to inching the technology closer to commercial use. Though there are several ways to capture CO2, flue gas is often bubbled through a sorbent that then has to be heated to release the CO2 for collection. That additional heating takes energy, usually energy that's provided by the polluting power plant itself.

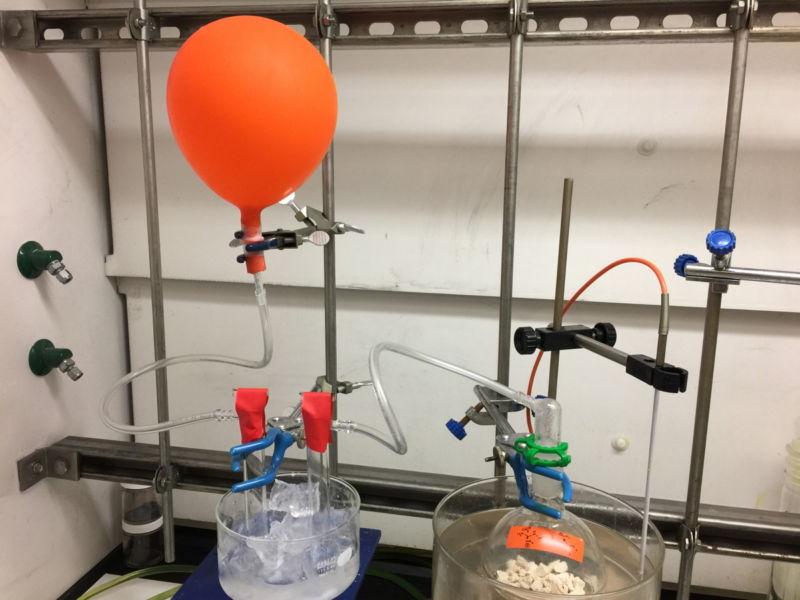

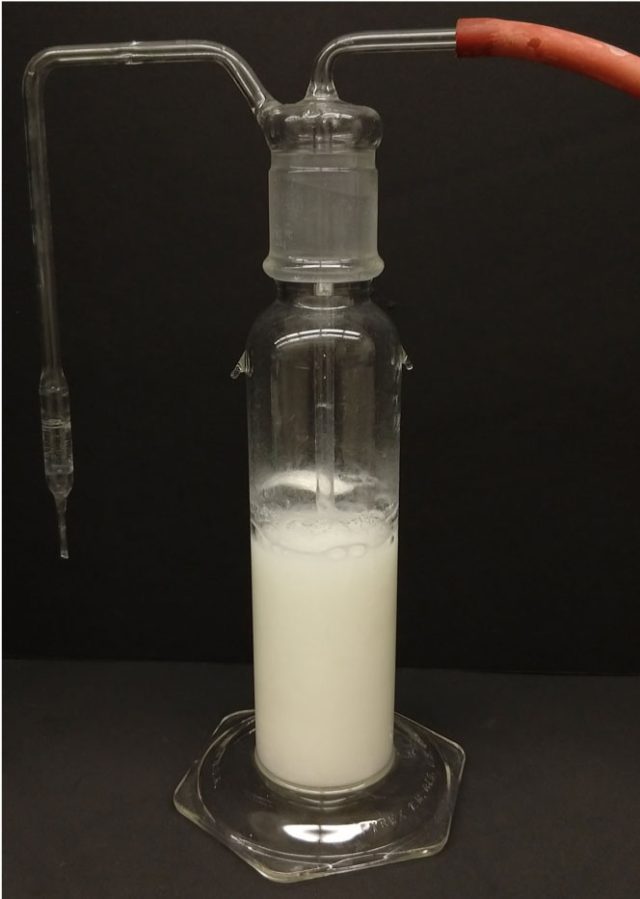

The Oak Ridge process involves an aqueous solution that reacts with CO2 to form a solid salt. Once separated, "mild heating" of the salt releases the CO2 and regenerates the sorbent, allowing it to be recycled, according to the paper.

The discovery was a bit of an accident, according to a press release on the findings. The researchers were studying a class of organic compounds called bis-iminoguanidines (BIGs), which have properties that seemed to lend themselves to capturing CO2 molecules. The BIGs, the researchers say, are "a thermodynamically more favorable alternative to CO2 separation," and only require heating to 120°C to release the captured carbon, as opposed to higher heats required by current sorbents.

The researchers ran ten consecutive carbon-capture cycles using flue gas and found that the sorbent repeatedly captured CO2 "with only three percent observed decrease in the CO2 absorption capacity." In addition, the sorbent "showed no signs of decomposition even after one week of continuous heating at 120°C in air."

It's hard to tell whether this sorbent will make much of a difference in carbon capture. Ars spoke to Emre Gençer, a research scientist at MIT's Energy Initiative, who noted that the benchmark amine that this sorbent improves upon is not the same as the commercial sorbents that companies have used at Petra Nova and Boundary Dam. Those commercial sorbets are proprietary (PDF) and more efficient than MEA already.

The paper also doesn't do a cost analysis, so it's hard to tell if this sorbent improves on that other main sticking point for carbon capture: cost.

Still, Gençer said that the paper is interesting and the concept has room to be improved and refined, though he wondered if introducing a new sorbent now may be too little, too late. "The scale we're looking at is in the billion tons: not only coal power plants but all carbon needs to be captured to mitigate climate change. We are looking around four billion tons of CO2 capture per year, to make an environmental impact," Gençer told Ars. That doesn't just include power plants, that includes carbon from industrial processes as well.

"It is very important for people to work on capture processes," Gençer said, while adding, "We basically need policies to accelerate this process."

The researcher noted, "The scale we're looking for capture is very large and we're already late in developing these new processes. The urgency is to really start implementing."

Tax credits to the rescue?

Gençer's concerns aren't idle. Despite the massive strides made by renewable energy and energy efficiency, economic growth and weak or non-existent carbon policies have contributed to two years of increases in the amount of carbon dioxide released into the atmosphere.

But a report released this month from the Clean Air Task Force (CATF) is significantly more optimistic about the future of carbon capture. Just last year, Congress passed a budget that increased and extended a tax credit for power generators per ton of carbon captured. CATF built a financial model of industry responses to this tax credit, called "45Q," and found that it "leads to significant deployment of [Carbon Capture and Storage], capturing and storing approximately 49 million metric tonnes of CO2 annually in 2030." (For context, current US emissions are in the neighborhood of 7 billion metric tonnes.)

The model also showed that this relative explosion in carbon capture doesn't hinder the deployment of renewables at all (that is, power companies won't chose to forego renewable deployment in favor of carbon capture deployment). "Electricity generation and corresponding emission reductions from renewables remain unaffected by the availability of 45Q," the report states.

Still, the report admits that this won't be enough. If carbon capture is going to play its role in reducing CO2 emissions enough to keep the globe from heating more than 2°C, "45Q incentives would need to be accompanied by additional policy actions and incentives to increase the pace at which pipelines and injection sites are permitted, financed, and built."

Unfortunately, despite this positive outlook, not many carbon-capture projects are actually being built in the US. According to Third Way's carbon capture map, which was updated in July 2018, only three plants are in a nebulous "planning" stage, and only two carbon capture plants are actually being built (one by NetPower and the other by LanzaTech).

Clearly, a lot more has to be done if US leaders want to make carbon capture a worthwhile investment. Until then, incremental developments in the science of carbon capture will have to suffice.

Chem, 2019. https://doi.org/10.1016/j.chempr.2018.12.025 (About DOIs).

reader comments

67