In 2010, a New England food processor found itself with a problem. For its wastewater, it was operating a biological treatment system equipped with looped chord trickling filter technology. That system was both antiquated and labor-intensive to operate and maintain.

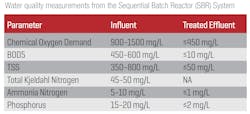

There were multiple areas of the system that were overwhelmed with chemical oxygen demand (COD), biological oxygen demand (BOD) and total suspended solids (TSS). The operator was having difficulty operating the system successfully due to the complexity of the process and the inability to maintain consistent system performance.

The Objectives

The processor’s management was looking for a solution that could handle the existing organic loading conditions without the complexity for operating. They also needed to increase the process capacity to handle 100,000 gallons per day (GPD) of wastewater with minimal staffing and maintain consistent performance to meet the discharge standards set forth by the local POTW authorities.

The Solution

A sequential batch reactor (SBR) system engineered and design by CDM Smith was installed in 2012 using MTS Jet Aeration and Decanter technology. The SBR system was sized and designed to process 100,000 GPD of organic wastewater.

The system operates four SBR batches per day at 25,000 gallons/batch over six days per week. The SBR system has been successfully treating organic wastewater with just one fully manned operational shift per day. The SBR system is automated via a SCADA system and telemetry to allow the operator to access the SBR process with a smart phone. This allows the operators to successfully operate the system without encountering process issues.

Over the past year the system has been further optimized by the facilities engineer to treat upward of 140,000 GPD by expanding the range of the MTS decanter and adjusting the sequential batch reactor process to process 30,000–35,000 gallons per batch. The MTS Jet Aeration System Manifold has proven to be highly efficient in oxygen transfer and the system has had no “in-tank” maintenance over the past 8 years of operation. The Jet Aeration System undergoes a pneumatic air-lift flush-out procedure to periodically clean the fiberglass manifold using the MTS back-flush jet cleaning system. The submersible pump was recently rebuilt due to a bearing failure and returned to a fully operational condition within a day. A spare pump has recently been purchased as a shelf spare as recommended by MTS for all Jet Aeration Systems.

The decanter discharges very clear effluent with very low TSS and turbidity — even during a foaming event that was created during a biology re-acclimation process after the system recovered from a peracetic acid toxic shock that occurs periodically from excessive clean-in-place procedures and facility washdown and disinfection. The recovery period is rapid based on the SBR System design and built-in process resiliency. The food processor facility engineer said the MTS System has been highly reliable and that he would not hesitate to recommend the MTS Jet Aeration System and SBR technology to others. He also stated that he will use MTS Jet Aeration Technology for future SBR expansions if, and when, the facility undergoes an expansion. WT

About the author: Dan Turner is the founder and president of Blue Whale Technologies, providing consulting engineering on special projects for Mass Transfer Systems, North American Filtration and a variety of industrial clients. Mass Transfer systems is a leading technology provider of jet mixing, jet aeration, SBR decanters and aspirators for the municipal and industrial wastewater treatment marketplace. North American Filtration provides a variety of filtration and water treatment products for water and wastewater treatment including jet aeration/mixing systems, pressure leaf filtration, centrifuge technology, water sensors, clarifier baffles along with commercial pool filtration systems.