The discovery of graphene—a one-atom-thick sheet of covalently bonded carbon atoms—inspired the research community to generate a variety of 2D materials. Graphene, MoS2, the silicon equivalent of graphene, and more all have distinct properties based on the chemical bonding among their component atoms. And it's possible to leverage these properties to create commonplace devices on an unprecedentedly small scale, like a three-atom-thick LED.

Obviously, the more materials we have to work with, the better we can fine-tune one of these devices to our needs. But producing 2D materials is a challenge, as there are a limited number of substances that lend themselves to the chemically bonded layers we know how to work with. Now, an Australian-US team (writing in Science) has devised a way to make a broad class of atomically thin metal oxides, including 2D versions of materials already in use by the electronics industry. Their secret? A room temperature liquid metal.

Selective

This is one of those cases where a series of simple observations led to a major development. In many cases, pure metals will react with oxygen in the air to form a thin oxide layer on their surface. This, it turns out, is true for one of the metals that is liquid near room temperature: gallium, which melts at 30 degrees Celsius. Leave some liquid gallium exposed to the air, and it'll form a thin film of gallium oxide on its surface.

The key observation came when the researchers looked into a gallium alloy, galinstan, composed of gallium, indium, and tin. Even though the two other metals could comprise as much as 40 percent of the alloy, the surface oxide ended up being pure gallium oxide. The liquid metal turns out to be key here. In a solid chunk of metal, oxygen will only be able to react with whatever metals are on the surface, whether they're the most energetically favorable or not. But a liquid allows all its components to cycle up to the surface, producing a chemically uniform film. That film then prevents oxygen from reacting with anything underneath it.

From there, it's a matter of simple thermodynamics. Of the three potential oxides, gallium oxide is the most energetically favorable to form. So, the researchers reasoned, if there's another metal in the alloy with an oxide that's favored over gallium oxide, it should end up being the one that's oxidized on the surface.

To test this, the researchers tried three very different metals. One of them (gadolinium) is a rare-earth metal; a second (hafnium) is a transition metal; and the third was aluminum, which is at the edge of the non-metals on the periodic table. Hafnium is especially interesting, as semiconductor manufacturers have been using hafnium oxide as an insulator in their transistors. Each of these is soluble as an alloy in gallium, and formation of their oxides is more energetically favorable than gallium oxide.

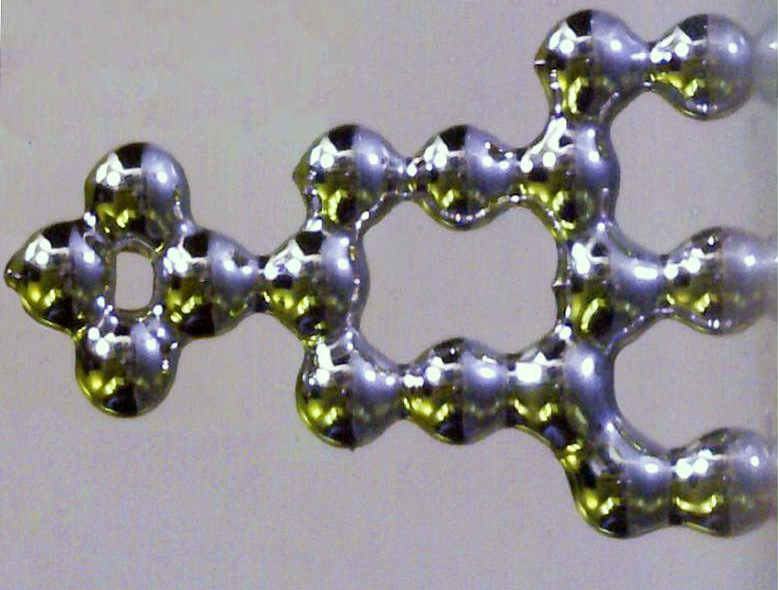

To obtain the oxide layer, the authors used what they term a "van der Waals exfoliation technique." That's jargon for "we pressed a microscope slide against the liquid metal and hope the oxide stuck to it." Stick it did. Microscopy showed that, for each of the three metals, sheets of a thin film up to a micrometer across remained on the surface of the slide. The researchers confirmed that these were pure oxides of a single metal, the one they targeted, even though that was only about one percent of the liquid alloy. Atomic force microscopy showed the sheets were a nanometer thick or less, consistent with them being atomically thin.

Bubble, bubble

Next, the researchers tried bubbling air through the liquid metal and into a layer of water placed on top. Conceptually, the air bubbles should form metal oxide layers on their way through the metal and deposit them into a suspension in the water. From there, they could be transferred to other surfaces as needed.

The reality, however, didn't work especially well. The aluminum and gadolinium alloys ended up reacting with the water, so they couldn't be used. Hafnium oxide sheets were produced with this approach but ended up disorganized and with bits of metal stuck to them. While there are some obvious improvements that could be made—like switching from water to another solvent—this approach clearly needs a bit more work.

Still, the method worked well enough for the researchers to obtain some hafnium oxide sheets, which they then placed on top of a metal electrode. Hafnium oxide is used as an insulator, and it worked well in this regard, even though the sheet was atomically thin. The result was a defect-free insulating layer that was only about half a nanometer thick, something that semiconductor manufacturers might find rather interesting.

This work was clearly a proof-of-concept, similar in nature to when researchers discovered that they could obtain graphene by peeling off layers using adhesive tape. That procedure was never going to scale to mass production. Here, the method that could scale (bubbling air through the metal) didn't actually work. But the key thing is that both of these developments highlighted the potential of the materials.

In this case, the potential is in the incredible flexibility. It should be straightforward to create a huge variety of 2D metal oxides, each with distinctive properties—electronic, magnetic, and catalytic differences are all options that the researchers mention. It's also possible that this might work with gases other than oxygen, if the reaction conditions can be tweaked.

Science, 2017. DOI: 10.1126/science.aao4249 (About DOIs).

reader comments

33