Offshore staff

TRONDHEIM, Norway – OKEA has found a solution for handling hydrogen sulfide (H2S) present in production from the Draugen field in the Norwegian Sea.

It involves a combination of reduced chemical discharges of chemicals, reduced cleaning of hydrocyclones, a lower oil content in the produced water and a lessened need for modifications.

OKEA estimates the associated annual savings in the range NOK 8-12 million ($0.85-1.2 million).

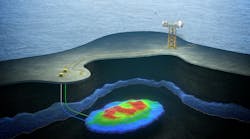

The company and its partners are applying a chemical which removes the H2S and have at the same time installed a line down to the subsea wells which ensures that the H2S scavenger reaches its target.

Under the field’s original developer Norske Shell, seawater injection started in 1994 in order to maintain pressure in the reservoir.

The reservoir contains bacteria that reduce sulfate to H2S, and when the seawater reaches the production wells, it is accompanied by the H2S, with potential for corrosion damage.

This can cause iron sulfide to develop, often wrapped in an oil film, which in turn results in more oil in the produced water, OKEA said.

Over time, Draugen has experienced increasing amounts of oil in the produced water, which has to be treated with an H2S scavenger in order to reduce the content of sulfide in the water prior to lowering the pressure. But the platform is relatively old, with a limited number of injection lines.

According to the project’s manager Ragnhild Nautnes: “We invested a significant amount of work into identifying other injection lines, and we finally succeeded. Using an ROV, we opened this in March and tested whether we were able to inject the H2S scavenger into this line.

“Injecting chemicals from the platform to the well takes 20 hours, and then 3 hours for the wellstream to reach the platform again. H2S was measured at the time of the expected flow back, and we saw a significant reduction in the H2S content…”

The volume of H2S in the well stream was more than halved, from 170 to 60 ppm, which in turn allowed the use of H2S removal chemicals on the platform to be halved.

At the same time, the level of oil-in-produced water improved significantly. Typically, hydrocyclones, which separate oil droplets from water, must undergo chemical cleaning each month, but on Draugen, this has not been necessary since March.

OKEA added that the use of water purification chemicals known as flocculants is also unnecessary. This is likely due to iron sulfide no longer forming.

Results so far suggest new, and potentially expensive, modifications to the platform may not be needed. Without the new measures, the volume of H2S produced would have increased on the facility.

At the same time, using an H2S scavenger subsea halved the volume of that would otherwise be needed topsides, and this should result in increased capacity for removing H2S on the platform.

Nautnes said there had been a close collaboration with Schlumberger for this project, the latter having presented various proposals when OKEA assumed operatorship from Shell.

The two companies now plan to create a product combining an H2S scavenger and a scale inhibitor. Laboratory test results have been good so far, with testing set to continue through the summer.

The product could be injected into the reservoir during the fall, resulting in further cost savings, if successful.

07/14/2020