At Ars, we get a lot of pitches from start-ups that want to talk about their products. At least for this science reporter, the feeling is rarely mutual. But once in a while, something piques my curiosity. Something like… carbon capture for an office HVAC system.

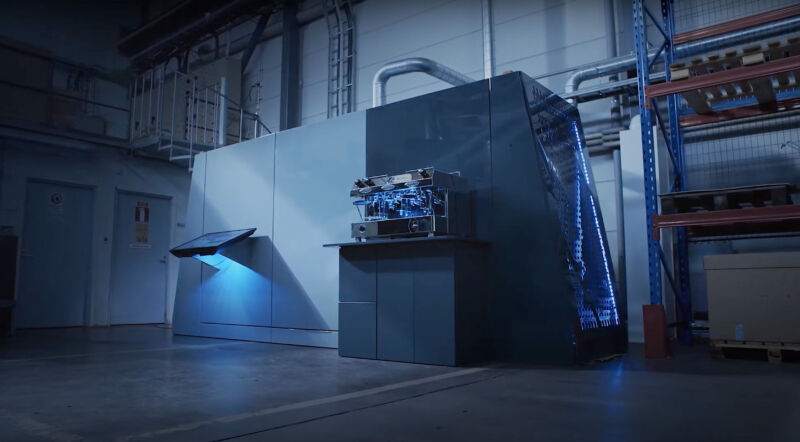

Over a video call, Finnish start-up Soletair Power recently showed off a unit operating in its office. It had been built for the 2020 World Expo in Dubai, but, well, you know what has happened to expos. Instead of powering an expo booth, there was a gas-powered espresso maker bolted onto the unit—since this machine turns CO2 into methane fuel.

The value proposition for the first part of the device is pretty straightforward. Carbon dioxide accumulates in buildings full of people, and higher CO2 concentrations may impact your ability to think clearly. The usual way to manage that is to introduce more outside air (which may need to be heated/cooled). Another could be to selectively filter out CO2. This device could do the latter for you.

That CO2 could simply be vented outside or used to produce an unwieldy amount of seltzer. Instead, what makes Soletair’s idea more interesting is that the rest of its device turns the CO2 into fuel. The configuration the company demonstrated makes methane but could be swapped for a liquid fuel process. Depending on the source of the energy running the machines, these fuels could be carbon-neutral since the carbon comes from the air. Whether it’s economically viable is another question.

Carbon makeover machine

The CO2 capture technique they’re using is a scaled-down version of those designed for combustion power plants. Air goes through a chamber full of small granules that contain amines—compounds that bind with CO2 molecules. Periodically, the granules are cycled through a heating step. The temperature only needs to rise to shy of 120°C, Soletair’s Petri Laakso and Cyril Bajamundi told Ars, so steam from the local heat system and/or an electric heating element is sufficient. This makes the amine granules release the CO2 they’re holding, which accumulates in a storage tank. The granules are then ready to absorb more CO2.

The other two-thirds of the machine, which measures about 2 meters tall, 5 meters long, and 1 meter wide, deal with turning that CO2 into a usable fuel. First, there’s an electrolyzer that splits water to make hydrogen gas. Then hydrogen is combined with CO2 in a methanation reactor to produce pure methane gas.

The Soletair had a Bunsen burner roaring for this demonstration, and the company mentioned having run a cook stove in the office previously. (And of course there’s that espresso maker…) The viability of this whole concept pivots on the fuel providing value somewhere.

As a CO2 filter, this unit is built to handle a standard HVAC flow of about 3 cubic meters of air per second. That can serve an office building with a few hundred occupants, Soletair says. In the company's own, smaller office, the filter was taking in air with about 500 parts per million CO2 and cutting that concentration in half.

Generating fuel is not a common office building function, though. If you have an on-site use for it (heating? vehicles?), the prospect might interest you. But Soletair also said that its local gas utility is amenable to having it sent into the public supply network—like net metering of solar electricity but for gas. It doesn’t sound like that scheme risks running a profit, but it could offset some cost.

The “air to fuels” idea is being pursued by companies like Carbon Engineering that are designing industrial-scale carbon-capture facilities. It’s interesting to see that attempted in a much smaller package, albeit with the focus shifted away from fuels production and toward indoor air quality. As with all forms of carbon capture, placing a cost on carbon emissions could improve the economics of expenditures that reduce emissions. But in this case, Soletair is primarily selling something other than the societal climate benefit—though making your own fuel is a fun add-on.

reader comments

131