By Saroj Tripathi, Vice President, Bristlecone Inc.

Saroj is a supply chain thought leader with more than two decades of experience in partnering with global organizations in their journey to digital transformation and technology enablement. Tripathi has served in a variety of roles in his 18 years at Bristlecone. He currently oversees North American Field Operations and Supply Chain Apps, responsible for everything from customer acquisition through customer satisfaction.

The year of 2020 has become synonymous with ambiguity, uncertainty, and volatility. The disruption caused by the pandemic is being compared to the third world war and is said to have removed a decade of growth and development.

Adopting and implementing efficiencies is more important than ever, organizations across the globe are reviewing their supply chains operations and how they manage them. Now more than ever there is a need for sustained and broad-based innovation in supply chain management to create the supply chains that are intelligent, auto learning, agile and resilient. Echoing the market reality, Bristlecone’s President and CEO, Nirav Patel says:

“To be in tandem with the pace of change caused by this black swan event, organizations need to discard dated, traditional modes of supply chain management and move aggressively towards building a digitally resilient supply chain ecosystem”.

AI is the first among key technologies that can enable a digital supply chain. Even though AI has a deep penetration in pretty much all aspects of our lives, within the enterprise and especially in supply chains the main streaming of AI solutions is still nascent. “It is useful to look at AI through the lens of 3 key capabilities rather than technology” (MIT Center for Transportation & Logistics).

- Cognitive Automation – intelligent automation of repetitive tasks

- Cognitive Insights – detecting pattern, prediction & prescriptive insights

- Cognitive Engagement – engaging various stakeholders

Of these Cognitive Insights can create the biggest impact in supply chains today. AI driven insights can help organizations answer key questions across the supply chain right from suppliers all the way to consumers:

Based on conversations and engagements with 200+ customers across 18+ industry verticals, we are clearly seeing a few key problems and themes emerge.

1. Supply chain risk management

If there is one thing that the COVID-19 outbreak has taught us is that while we cannot predict unforeseen events, we need to leverage AI to understand the impact of such events on our supply chains and how we can use prescriptive insights to mitigate the risk. Even before the pandemic, supply chain risk management was on top of mind of leaders with disruptions resulting from severe weather, tariffs, regulatory changes, industry changes and technology shifts.

AI can enable proactive risk management by:

- Continuously monitor global and local events by processing unstructured and semi-structured data streams

- Contextualize the risk to the organization’s supply chain and quantify the risk parameters

- Provide prescriptive insights on risk mitigation and management strategies by looking at impact of past events and changes to key supply chain operations variables

Traditional Supply Chain risk management strategies were focused on creating static risk registers and creating mitigation strategies that were put on dusty shelves. With AI, supply chain risk can be managed and mitigated with near real time data processing and prediction capabilities in addition to bringing judgement with learning systems. For example, severe weather events have a direct impact on customer deliveries, logistics costs and worker safety. Many organizations have SOPs in place to manage such situations but applying those in real life is difficult. Using AI, a consumer durables manufacturer is analyzing weather and order data in real time, so when the snow roles in – they are able to avoid any last minute logistics rescheduling costs, enhance customer experience with proactive alerts and enhance driver and cargo safety.

Learn more about AI in Supply Chain Risk Management

2. Demand volatility

Traditional supply chain demand planning systems rely extensively on extrapolating historical data. These conventional methods consider expected deviations like seasonality and promotions. However, neither the current market situation can be predicted by simple statistical forecasting and nor can the future be forecasted based on the current data. Demand patterns have changed drastically:

- Consumers aren’t buying certain things. Ex. High end electronics, cars

- Consumers are buying certain things in much smaller quantities, ex. Make up, formal clothing

- Consumers are buying more and consuming faster ex. Cleaning supplies

- Consumers are buying from new channels ex. Ecommerce vs. brick & mortar retail

AI can help improve forecast accuracy in the time of uncertainty in two critical ways:

- Empowering the statistical forecasting with machine learning algorithms that are self-learning and progressively improve forecast

- Model external demand drivers that are pertinent to the industry, product line and markets which provide correction based on prevailing ground realities

Traditional methods of forecasting failure even faster in the case of new product introductions where there is no historical data available. For automotive aftermarket, new product demand is impacted by the profile of vehicles in operation (age, make, model, failure rate), seasonality, local operation conditions, exclusivity of parts with added complexity of multiple channels and a very competitive landscape. Using AI techniques not only helped the product managers determine the factors but also understand the weightage of the factors leading to significant improvement in forecast accuracy, better inventory optimization and higher return on working capital.

Learn more about AI in managing demand volatility.

3. Supply chain visibility & traceability

“Where is my order?” is possibly the only question that you a Supply Chain professional can ask in her office and at her home. Even in 2020, lack of supply chain visibility continues to be a major bottleneck in the optimization of supply chain operations. The problem complexity is compounded for players in regulated fields like pharmaceuticals and food & beverages where not only do they have to ensure a great customer experience but ensure safety and compliance to state and federal guidelines. The ability to answer to key questions:

- Where are my assets

- How are my assets

Comes from combining the information data stream with the physical movement data stream.

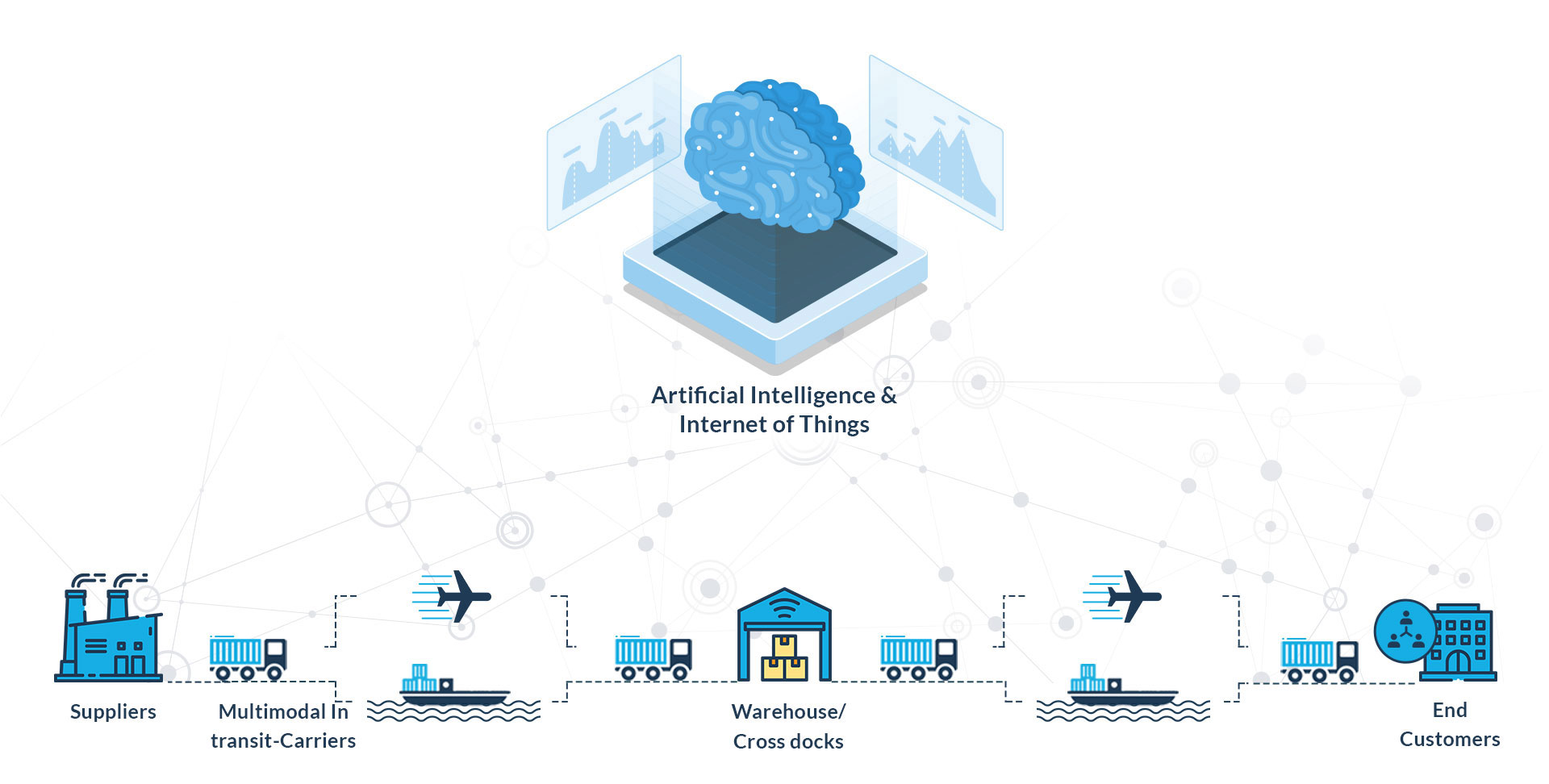

Shipments can be traced using a spectrum of tracking technologies, starting from bar codes going all the way up to active IoT sensors. AI can help process this data at scale – for a global supply chain – the tracking data can come from 3PL partners & carriers, owned truck fleets, ocean freight, field sensors and key supply chain transactions with tens of thousands of shipments in transit at a given moment. In addition, using machine learning proactive alerts can be generated on movement of goods impacting customer experience as well as quality of the goods impacting safety & compliance. In this case, AI becomes a key value add or enabler to another key supply chain digitization technology — IoT.

Learn more about using AI & IOT to enhance you supply chain visibility & traceability.

Supply Chain digitization continues to be a priority for leaders across the globe irrespective of the industry you compete in. AI can significantly boost the strategic advantage of your end to end supply chain from supplier to consumer.

Bristlecone Inc., part of the Mahindra Group, is a trusted partner in supply chain transformation, specializes in helping organizations create higher performing environments and deliver positive customer experiences. With an extensive network of customers across multiple industries and key technology partners, Bristlecone Inc creates value at the intersection of deep supply chain knowledge and bleeding edge technology expertise with a focus on fast innovation cycle and reduced time to value.