A European consortium is now using a 1-kW "dot matrix" ultrafast laser system to create antifouling hydrophobic surfaces on metal or plastic. The surfaces could soon replace the toxic varnishes used in ship coatings to stop algae or barnacles sticking to hulls, which would reduce maintenance costs, fuel bills, and CO2 emissions. Such "biofouling" by algae and other organisms is currently a big problem for marine craft.

The European consortium consists of the Fraunhofer laser technology research institute ILT and the Chair for Technology of Optical Systems of RWTH Aachen University from Germany, Amplitude Systèmes, LASEA France, AA OptoElectronic from France, and LASEA from Belgium as industrial research and development partners.

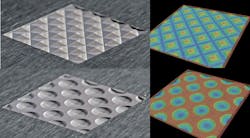

The laser system creates flow-optimized metal or plastic surfaces that can reduce drag by imitating the skin of sharks. Shark's flesh is covered in millions of microscopic denticles (protruding scales, reducing drag to make the shark a highly efficient swimmer. The consortium's laser etches microscopic spike structures to create a rough surface that reduces drag and inhibits the growth of bacteria, algae, and barnacles.

MultiFlex is supported by the European Commission in the framework of the EU Horizon 2020 ICT programme with a grant of € 4.7 million under the Photonics Public Private Partnership.

"Besides maritime components, application fields can be found in aircraft and turbomachinery," says Johannes Finger, coordinator of the MultiFlex project. "Here, surface structures might inhibit cavitation and thus improve lifetimes of propellers of propulsion systems or water turbines."

The laser system splits its single beam into a grid of 64 beamlets, where every beamlet can be turned on, off, positioned, and individually tuned.

"Our system will ablate more than 150 mm3 in one minute, therefore making it hundreds of times faster than existing technologies," says Finger.

Projected applications include:

Tool and mold manufacturing -- MultiFlex could make many USP mold and tool making applications, such as fabricating venting holes or microcavities and making textures on free-form surfaces, more cost-efficient. Tool and mold application is the first field where the technology will be validated.

Automotive -- By delivering high throughput for USP surface processing technology, MultiFlex can tackle microstructuring applications for interior lighting, instrument clusters, and aesthetic and haptic structures.

Electronics -- Increasing the spread of ultrafast processing in electronics will improve the performance and reliability of high-performance electronic components. Ultrafast-laser-based fabrication of via holes and technical ceramics for high-performance electronics will be significantly improved.

Printing and embossing -- The MultiFlex system has the potential to significantly increase electronics printing, precise embossing of microstructures, and the fabrication efficiency for high precision tools.

Source: Photonics21