Researchers develop breakthrough cooling system that does not use any electricity

Researchers at the Massachusetts Institute of Technology have developed a cooling system that does not use any electricity.

‘Passive cooling’, as the technique is called, could preserve food crops and supplement conventional air conditioners in buildings while only needing a small amount of water to operate.

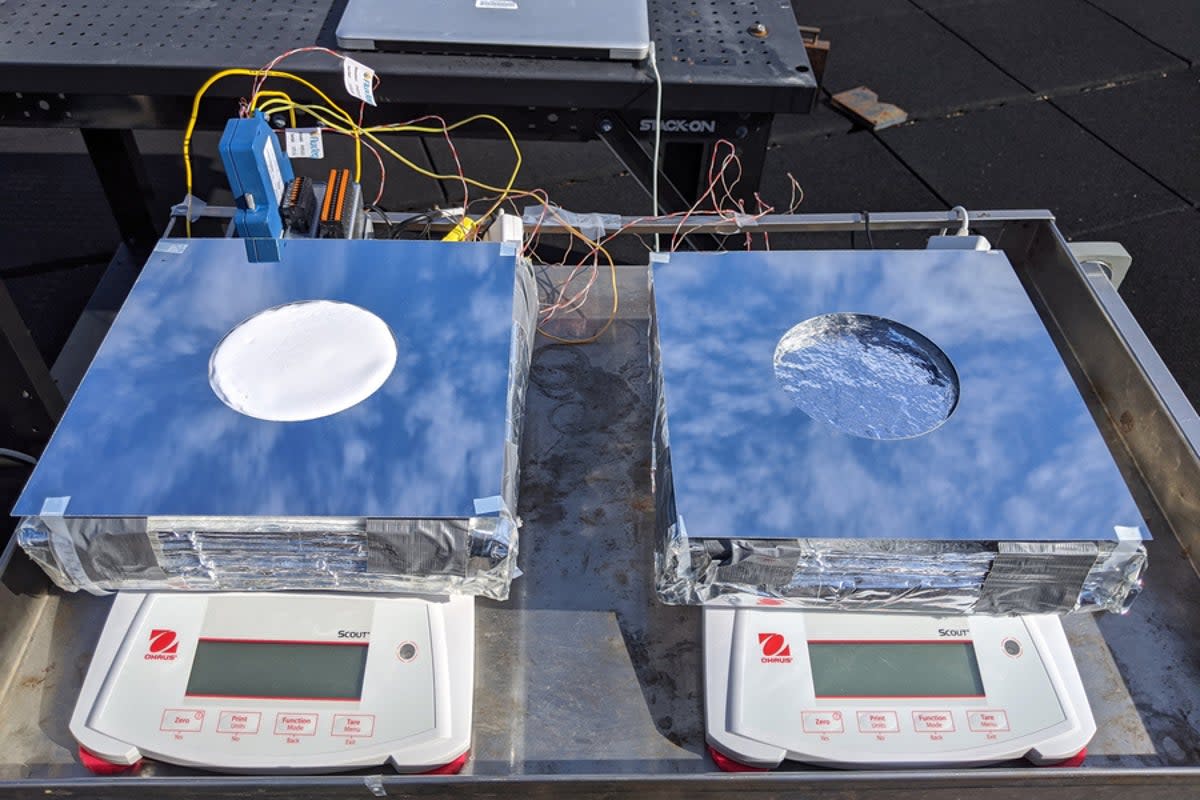

The system – which combines radiative cooling, evaporative cooling, and thermal insulation in a small housing that looks similar to a solar panel – can achieve 9.3 degrees Celsius of cooling. It is made up of three layers of material: one of a sponge-like polyethylene known as aerogel, one layer of hydrogel, and finally a reflective layer.

The aerogel is highly insulating, while also allowing water vapour to pass through, cooling the system; below that is the hydrogel – another sponge-like material, but one whose pore spaces filled with water rather than air – which provides the water source for evaporative cooling. The mirror-like layer then reflects any incoming sunlight that has reached it, sending it back up through the device rather than letting it heat up the materials and thus reducing their thermal load.

The system was tested in a small enclosure just 10 centimetres across, which the researchers say proves its effectiveness in suboptimal conditions.

“This technology combines some of the good features of previous technologies such as evaporative cooling and radiative cooling,” MIT postdoctoral researcher Zhengmao Lu said.

This combination “show[s] that you can achieve significant food life extension, even in areas where you have high humidity”, which limits the capabilities of conventional evaporative or radiative cooling systems. It is claimed that the cooling could be used to store food up to 40 per cent longer in humid conditions, and three times as long in drier conditions.

However, holding back this technology is that the aerogel is expensive to produce, due to the fact it needs special equipment to remove solvents without damaging it. It is possible that freeze-drying or using alternative materials may be able to provide a similar function at a lower cost.

“The aerogel is the only material that’s a product from the lab that requires further development in terms of mass production,” Mr Lu said, but it is unclear how long such research would take.

"By combining evaporative cooling, radiative cooling, and insulation, it has a better cooling performance and can be effective in a wider range of climates than evaporative cooling or radiative cooling alone,” said Xiulin Ruan, a professor of mechanical engineering at Purdue University.

“The work could attract significant practical applications, such as in food preservation, if the system can be made at reasonable cost."