March 8, 2013

|

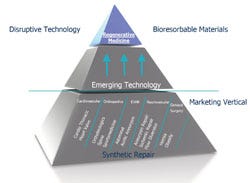

Synthetic material breakthroughs will play an important role in regenerative medicine's future. |

When it comes to the medical applications of synthetic materials like plastics, we may have just scratched the surface in terms of what is possible, believes Peter Gabriele, director, emerging technology at Secant Medical (Perkasie, PA. Future biomaterials have the potential of not only being tolerated by the body but closely integrating with it. "The designer of the material has the opportunity to integrate what is known about cell biology and material interaction with components," Gabriele says. This serves to either antagonize or improve the wound healing process. "The more we know about the mechanism of healing, the better we can get at designing polymers that can accommodate the wound healing process."

Basic constructs in synthetic textile repair could be transformed into biodegradable tissue scaffolds, Gabriele remarks. "The impact of coupling new biomaterials with precision textile engineering allows the tissue engineer the ability to control multiple functional tissue mechanical properties of the biodegradable with rational scaffold design."

By rational scaffold design, Gabriele refers to the concept of maintaining a homeostatic environment through deliberate engineering and modification of materials to meet the requirements of cell biology. "If you know that certain entropic agents, growth agents, or agents of cell biology are capable of eliciting a certain response by the tissue or cell, you're making a smart scaffold," he says. "You're designing the scaffold to accommodate the healing process. Putting a synthetic material in the body and hoping that the body accommodates the cell material is generally not a fruitful approach. "We can't disrupt what has been a part of the cell's development."

It follows that in the future, wound-healing science will inform the fields of regenerative medicine and tissue engineering. When a device is implanted into the body, the body must go through a healing process, which is a process similar to what occurs when the skin is injured, during which the body undergoes homeostatic inflammation, proliferation, and remodeling. "When a scaffold is implanted, the body undergoes these processes as well," Gabriele notes.

The Holy Grail for treating cardiovascular disease, according to Gabriele, would be to reconstruct a synthetic bioresorbable small-bore vessel less than 6 mm in diameter. "The challenge is to provide performance in a mechanically dynamic environment while simultaneously regenerating vascular tissue within a degradable scaffold," he adds.

Gabriele emphasizes the importance of being mechanistically oriented in the design of products. "By integrating materials that allow as close to normal functioning as possible, the healing process may restore original functionality that is as close as possible to the native tissue." This takes us back to the concept of rational design, he adds. "There are not only the events that occur as a result of polymer degradation in the strict sense of the chemistry of the polymer, but there is also chemistry of the wound and chemistry of the healing site that have to be understood." It's only when these two understandings converge that it is possible to make more sense out of what is needed. The only way to do this is to understand the mechanism of the chemical breakdown, healing, and interaction of engineering materials with the human body. These materials then have to be processed, making sure that stray, antagonistic contaminants are not introduced that can disrupt the healing process.

"The future rests on the concept of biodesign," Gabriele predicts. "When something is biodesigned, it addresses a criteria of everything from materials interaction with the body, compliance laws, and engineering limitations with respect to human physiology."

The engineering of bioresorbable implant devices is still a young field. "We're still learning a lot about tissue engineering, tissue regeneration, materials science, and materials interaction with the body," Gabriele notes. "With progress that's been made, we'll be able to start designing materials for the future. Key to this is the idea of metabolic breakdown products: creating bioresorbable materials where the body can handle the breakdown products safely as opposed to their being contaminants."

About the Author(s)

You May Also Like