In the centre of the factory stand 31 reactors: giant metal globes that can hold up to 10,000 litres of liquid each. Every week, gleaming stainless steel drums arrive by truck at this plant on the outskirts of Oss, in the Netherlands. Their contents are poured into the reactors through a funnel, dissolved, and then heated to boiling point. Standing by one of the vast containers, the factory manager, Robert Dam, compares it to a “cooking pot”. Peering inside, we can see the light liquid bubbling away.

At Dam’s factory, a white powder distilled from soya beans and shipped from China is turned into a precious commodity: strong synthetic oestrogen. The plant at Oss, owned by the Dutch subsidiary of South Africa’s largest drugmaker Aspen Pharmacare, produces the most potent variant of oestrogen, known as oestradiol, destined for the UK market. It will be added to gels, sprays and patches used by more than 1 million women in Britain to manage the symptoms of menopause.

Stretching from the fields of Heilongjiang in north-east China to the shelves of British pharmacies, the chain of agricultural, industrial and chemical labour involved in producing medicines for hormone replacement therapy (HRT) is as complex and global as for the manufacture of iPhones or cars. And like all supply chains, it is vulnerable to disruption.

In May of this year, reports of a shortage of HRT medicines, in particular oestradiol gel, began to surface. As economies reopened after the pandemic, shipping routes became jammed, compounded by shortages of materials, lorry drivers and many other workers. At the same time, demand in Britain surged, following a 2021 documentary produced by the TV presenter Davina McCall, which debunked concerns about the safety of using hormones to treat menopause.

The “Davina effect” caused NHS prescriptions to peak at nearly 700,000 in May, up from 380,000 a year earlier, representing a monthly spend of £9.4m, according to OpenPrescribing. With many pharmacies out of stock, women dependent on a daily dose to relieve some of the more severe symptoms of menopause – which can range from debilitating anxiety to insomnia – found themselves driving hundreds of miles to find products, paying large sums online, and even swapping personal supplies with strangers in car parks.

In April 2022, Madelaine McTernan, the former director general of the Covid-19 vaccine taskforce, was appointed HRT tsar to help manage the shortages. She was tasked with applying lessons learned from the successful procurement of vaccines to improving the supply chain. Aspen API’s factory in the Netherlands is a key part of that chain. The Observer was given exclusive access to the facility to observe a process about which very little has been published outside the pages of scientific journals.

The site produces 900 batches of hormones and other key ingredients for drugs every year, including oestradiol, another oestrogen variant called oestriol, and progesterone, which is often used in combination with oestrogen in the treatment of menopause.

Dirkjan van Zoelen, Aspen API’s manager of development and technical support, explains the process for making oestradiol. It begins with the mashing of soya beans to produce cooking oil in China. The beans are transported from the farm to a crushing plant.

A byproduct of this process is an oil rich in compounds such as stigmasterol, which occur naturally in plants and make good raw materials for the production of steroid hormones. The stigmaserol is then transformed, via a chemical process or via natural fermentation, into oestrone. The oestrone, a weak form of oestrogen, is reduced to a white powder and shipped to the Aspen factory.

Here, inside the reactors, its chemical structure is modified by adding sodium borohydride, a white powder, and methanol, which acts as a solvent to enable the reaction.

Once it has done its job, the solvent is removed from the crude oestradiol along with any other foreign materials like dust, using a filter dryer. In a final step, water is added to crystallise the oestradiol into a pure powder. “Oestradiol doesn’t like water,” explains Van Zoelen. “It forms a cluster of molecules. Any impurities that don’t fit into the orientation of molecules stay in the solution.”

Most of the process is automated. But the final stage is done by hand. Oestradiol, now a fine white powder with a defined particle size distribution, is weighed and dispensed inside sterile “glove boxes” – glass boxes that staff reach into by placing their hands through two holes and into arm-length gloves. Once packaged, oestradiol is transported to factories in other countries such as Germany where it is added to patches, gels or tablets, before being packaged and shipped to Britain.

Until 2013, when Aspen acquired the Oss plant from US group Merck, the facility produced oestrone on-site. But the manufacturing of oestrone and other ingredients was shifted to Asia to keep prices of generic medicines low. Van Zoelen says: “It’s a constant search to find ways to decrease cost: for some products it’s fighting for every penny.”

To ensure against shortages, Aspen has two suppliers in different regions of China. Factory closures imposed during the Covid pandemic, or under China’s Blue Skies initiative to curb pollution, can abruptly disrupt the flow of raw materials for drugs to Europe. “This is one of several factors that have caused the HRT shortages being experienced in the UK,” says Van Zoelen.

In a scene from the otherwise forgettable movie spin-off Sex and the City 2, Samantha Jones pleads with airport customs in Abu Dhabi not to confiscate her HRT drugs. “I need to speak to an ambassador, or an embassy, or someone in menopause,” she insists. The customs officer is unmoved. Deprived of her medicines, she spends her holiday ordering platefuls of yams from the hotel kitchens. They don’t seem to help much.

“It’s not that if we eat a lot of yams we’re going to have the amount of hormones in our body – it does have to be converted appropriately through a laboratory process,” says Dr Theodora Kalentzi, a menopause specialist at Medical Prime clinic in London.

During menopause, levels of oestrogen, progesterone and testosterone begin to fluctuate, and fall, producing physical and mental side-effects. Soya and wild yams contain a relatively high amount of the plant hormones stigmasterol and diosgenin respectively, and these are both similar in chemical structure to human hormones. However, while naturopaths may recommend drinking soya milk or ingesting wild yam powder, there is little evidence to suggest these foods can do much to stabilise hormone levels. Plants need to be altered in the lab to produce the so-called body-identical hormones used in HRT.

“Most plants contain steroid substrates called phyto-oestrogens – consider them plant hormones – which have a very, very weak oestrogenic effect when consumed by humans,” says Michael Buckley, medical director at the Australian firm Lawley Pharmaceuticals, which buys soya-based testosterone powder from the US to make testosterone creams.

“Today, most pharmaceutical-grade hormone production starts with soya as the raw source material for extracting stigmasterol, as it is easier to grow for large-scale commercial purposes than yams,” he says. “The conversion is pure chemistry and molecular manipulation.”

The discovery and distillation of sex hormones dates to the early 20th century. In 1929, the American biochemist Edward Doisy succeeded in isolating oestrone, unveiling his discovery at a symposium in Boston. Fuller Albright, an endocrinologist (a doctor specialising in glands and hormones) who was observing his presentation, went on to demonstrate that oestrogen could be used to treat hot flushes, bone density loss, and eventually to block ovulation. In other words, as a contraceptive.

The first commercially produced birth control pill was approved by regulators in the US in 1960. The use of hormones to treat menopause was popularised at around the same time, if not a little earlier.

after newsletter promotion

The Brooklyn gynaecologist Robert Wilson was a major influence. His now notorious 1966 book, Feminine Forever, conjured the idea of menopause as a disease, describing it as a “living decay”, which could destroy a woman’s “character as well as her health”. Blogging about the impact of Wilson’s book, his son Ron picked out a particularly startling passage: “The unpalatable truth must be faced that all postmenopausal women are castrates. A man remains a man until the very end.”

One of the most popular oestrogen brands on the American market was Premarin. Produced from 1942 by the Pennsylvanian company Wyeth, the name is an acronym: it stands for Pregnant Mares’ Urine. In his blog, Ron Wilson describes in unflinching detail the conditions in which the horses that produced it were kept. “To collect the urine, farmers in the United States and Canada confine some 75,000 mares to tiny stalls for six months at a stretch. Some of the horses receive exercise every few weeks, but most don’t see the light of day for months.

“The mares must also wear cumbersome urine-collection bags which chafe their legs and prevent them from ever lying down comfortably. Farmers are encouraged to limit horses’ access to water so that their urine will yield more concentrated oestrogens.”

Pfizer, which acquired Wyeth and still sells Premarin in the UK (it has a 3% market share), insists that it works with family-owned equine ranches in Canada “dedicated to the care of welfare of their animals”. The firm adds: “Pfizer has a long-standing commitment to equine care. All ranches that Pfizer works with are required to comply with a code of practice, which sets forth standards for the appropriate care, feeding and exercise in horses.”

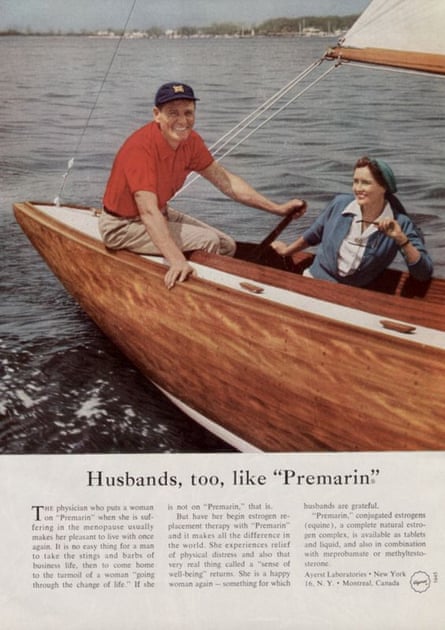

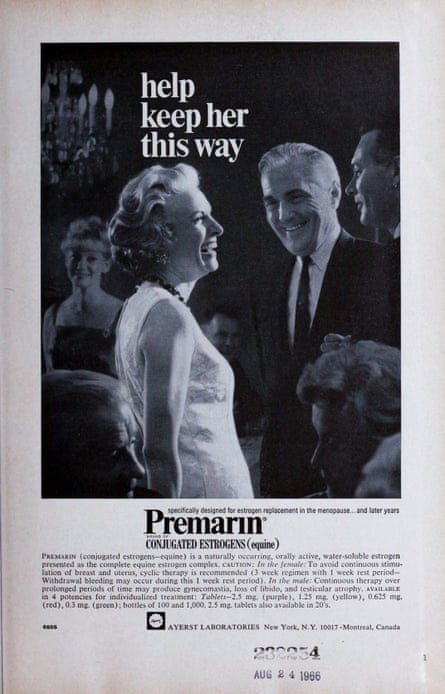

During the 1950s and 60s, Premarin was marketed to men as well as women, with magazine adverts claiming the pills made a woman “pleasant to live with once again”. “It is no easy thing for a man to take the stings and barbs of business life,” claimed one ad “then to come home to the turmoil of a woman ‘going through the change of life.’” In another, a photograph of a bus driver featured alongside one of an angry female passenger, with the headline: “He is suffering from estrogen deficiency. She is the reason why.”

Luckily for pregnant mares, other scientists were working out how to extract hormones from plants. An American chemist called Russell Marker headed south to Mexico in search of a giant tuber he had read about in a Texan botany book. The Mexican yam proved a perfect raw material for extracting large amounts of the chemicals needed for mass production.

Marker’s work had medical benefits too. So called body-identical hormones extracted from plants, particularly those made using modern methods, are associated with less risk in relation to breast cancer and blood clots than older drugs, says Dr Paula Briggs, chair of the British Menopause Society.

Prescriptions of HRT in England have more than doubled in five years. NHS data shows £85m was spent in the 12 months to the end of June this year. The global market was valued at $20bn last year, according to the market research firm Grand View Research, and it is expected to grow to $36bn by the end of the decade. The drugs are used to treat other conditions, such as hypothyroidism and growth hormone deficiency, but menopause represents the largest chunk of that spend.

Despite the size of the market, HRT products are mainly sold by smaller drugmakers that specialise in women’s health, rather than Big Pharma companies, with the exception of New York-based Pfizer. Manufacturing takes place almost entirely outside the UK, meaning importers are entirely reliant on international supply chains.

Oestrogel, one of the most popular products, is made by Besins Healthcare, a fifth-generation family-owned pharmaceutical firm founded in Paris in 1885, and now based in Brussels. The gel is manufactured in Belgium and France.

Theramex, a private-equity-owned pharmaceutical firm based in London, gets plant-based oestradiol from Hungary and progesterone from Italy to make its Bijuve capsules.

While UK shortages have started to ease, the British Menopause Society and campaigners including the MP Carolyn Harris are calling on the new health secretary, Thérèse Coffey, to introduce a national list, or formulary, of approved HRT medicines. They say this would ensure all women in the UK have the same access to the newer body-identical drugs, and companies like Theramex say it would encourage them to invest more.

The HRT taskforce was wound up at the end of August, after only four months, following what the government said was an improvement in the supply chain. Briggs agrees the situation has “massively” improved. But stocks of some products remain low, and pharmacies are still allowed to limit how much a customer can buy, or offer a substitute. These so-called serious shortage protocols, which limit dispensing to three months supply, are still in place for nine products.

“This prolonged fiasco with stock shortages of a number of HRT products is infuriating,” says Harris. “The government has been blaming the increase in demand but months down the line this is no excuse – it should have worked with suppliers to get the situation resolved far more quickly.”