Why it matters: Summer is coming, and A/C units will soon start humming to try and keep our homes and offices a bit cooler than the sunny hellscape waiting for us outside. But air conditioning comes with an enormous waste of electric energy, which in turns brings more greenhouse gases to an already boiling atmosphere.

As global warming is a phenomenon that sane-mind people can feel on their own skin, we are in desperate need for alternative cooling technologies that won't add any more harmful emissions to our overheating planet. A potential solution to this hot issue comes from passive daytime radiative cooling (PDRC), which is the ability of a surface to emit its own heat into space without it being absorbed by the air or atmosphere.

PDRC materials can become several degrees colder than the air around them, and with no need for electrical power or other external energy sources. Passive cooling surfaces could be embedded in buildings or cars, promoting a substantial cooling effect without using air conditioning units or other active, power-intensive methods.

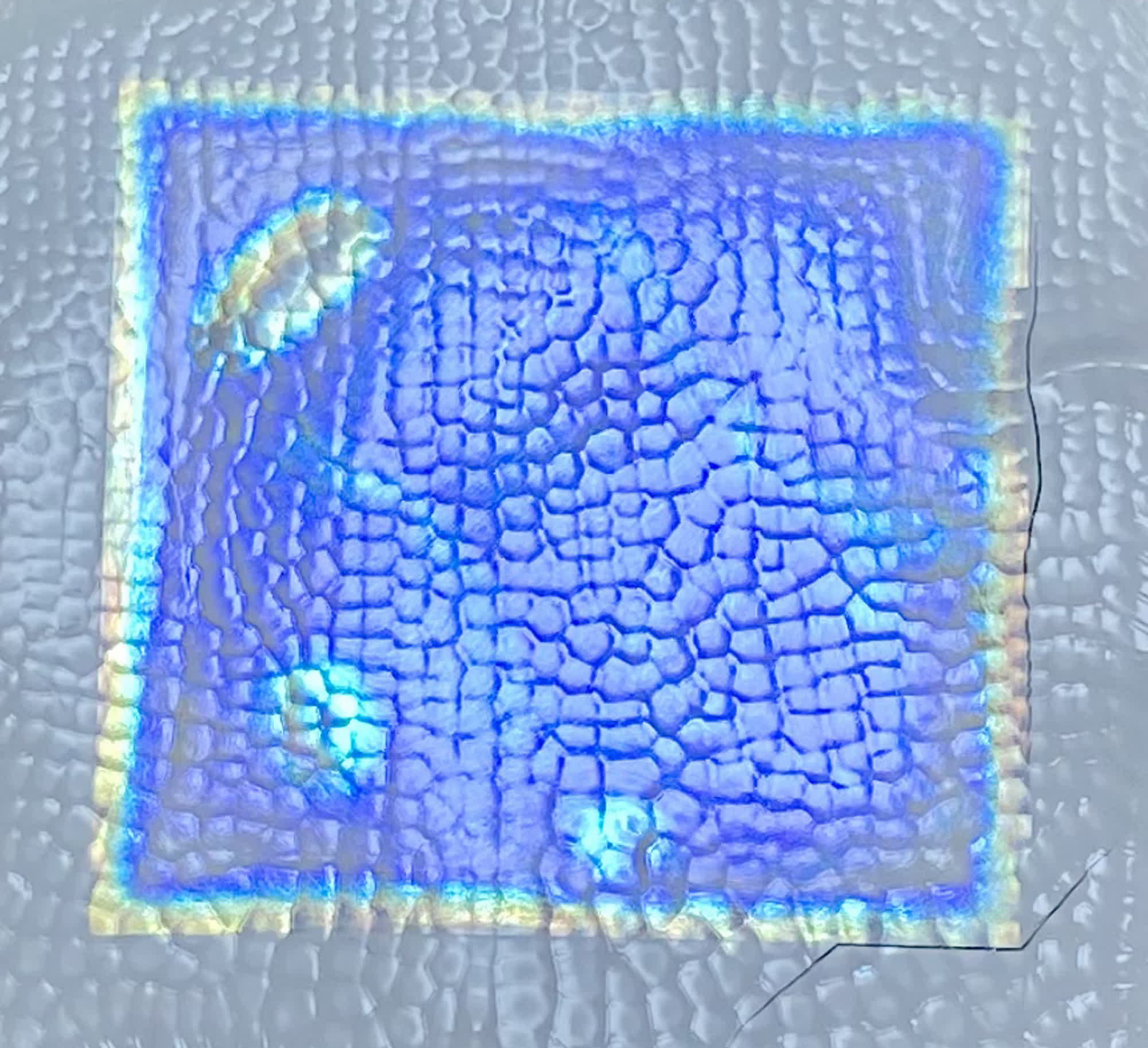

Researchers from Cambridge University, UK, are working on a novel cellulose film with PDRC properties, a plant-based, two-layered material that gets cooler when exposed to direct sunlight. The film can also be treated to provide bright, iridescent colors, and a variety of textures which would help with integrating the material in home furniture or automotive applications.

The UK scientists presented their results during the ACS Spring 2023 hybrid meeting, explaining how cellulose is one of the few naturally occurring compounds that can promote a PDRC effect. Adding a color pigment to a material is detrimental to the aforementioned PDRC effect, as pigments absorb specific wavelengths of visible light and only reflect the color(s) we see. The absorbed electromagnetic radiation is then turned into heat.

To solve the heating issue, the researchers focused on natural structures that can show a colorful effect that doesn't require the presence of a pigment. Something like the prismatic effect seen on a soap bubble, which is the result of the way visible light interacts with the bubble's surface at the microscopic level.

The effect is known as structural color, and Ph. D. Silvia Vignolini (the project's principal investigator) found that plant-derived cellulose nanocrystals (CNCs) can be employed to produce iridescent, colorful films with no addition of external color pigments.

Vignolini's team added a second layer to the iridescent, CNC-based film, using a white-colored material made from ethyl cellulose and finally creating a colorful, bi-layered film with PDRC properties. When placed under direct sunlight, the film was nearly 7F cooler than the surrounding air. Sticking together the two cellulose layers was the most difficult part of the research, the UK scientists said, but the final result can be adapted to a standard manufacturing line for mass production.