Damping Dynamics: Scientists Explore Methods to Enhance Structural Stability by Reducing Vibrations

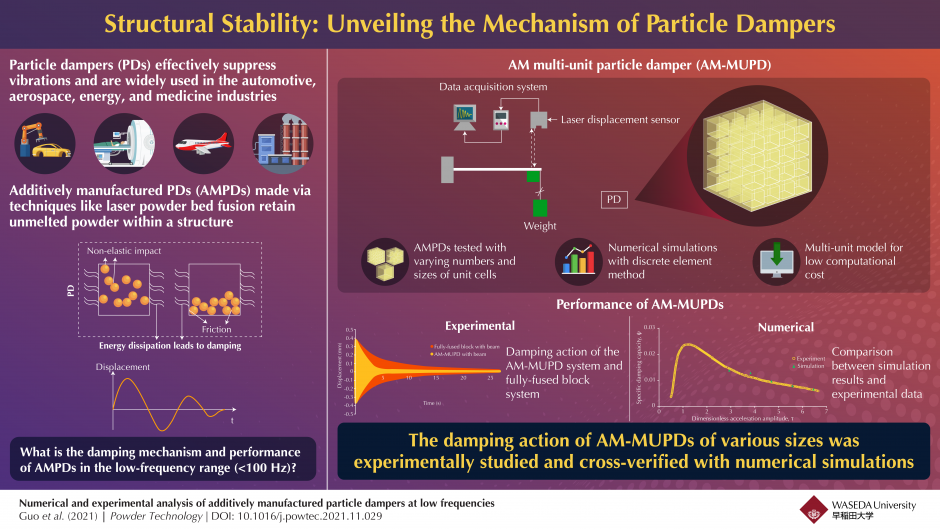

Particle damping is a helpful way to decrease vibrations and enhance structural stability by having particles absorb excess vibrational energy through impacts and friction with the walls. It’s applied in various sectors like the automotive, aerospace, energy, and medical industries. Among the various particle dampers available today, a method called “laser powder bed fusion” (LPBF), which is a method of additive manufacturing (AM), can create a new kind of particle damper by intentionally leaving some powder unfused inside the parent structure.

In a recent research project, a group of scientists from around the world, led by Professor Akihiro Takezawa of Waseda University, has studied how well these particle dampers work for vibrations that happen slowly, less than 100 times per second. Their study included both experiments and computer simulations.

In the study, the team created a multi-unit particle damper with the LPBF method denoted as AM-MUPD, which included small cubic unit cells inside. Numerous AM-MUPDs with different unit cell numbers, sizes, and cavity sizes were manufactured, and their damping performance was tested. The reason for this was that subdividing the internal space within the particle damper increases the number of particle collisions, which helps improve how well the damper reduces vibrations.

Dividing the AM-MUPD into smaller sections also reduces computational costs and the team used a computer simulation method called the discrete element method which treats each particle as a rigid body. It was used to examine how the particle damping system moves and loses energy, and to predict how well it can reduce vibrations. The simulations conducted with this method also matched the experimental damping, showing that this method is suitable for studying an AM-MUPD’s damping effectiveness.

In summary, this study examined the effectiveness of additively manufactured particle dampers using both experiments and simulations and investigated how unit cell size and number impact damping performance. This research is important because it required significant computational work, and there have been limited modeling studies on analyzing particle dampers made with additive manufacturing so far.

Link to the original journal article: https://doi.org/10.1016/j.powtec.2021.11.029

About the Author:

Akihiro Takezawa is a Professor in the Department of Applied Mechanics and Aerospace Engineering at Waseda University, Japan. He earned his Ph.D. from Kyoto University in 2009. With over 3700 citations and 96 papers, Professor Takezawa’s research spans areas such as control and system engineering, the mechanics of materials and manufacturing and production engineering. He is involved in various academic societies like the Japan Society of Mechanical Engineers and The Japan Society for Computational Engineering and Science. Additionally, he has received several awards, including the 2022 Waseda Research Award and the 2015 JACM Award for Young Investigators in Computational Mechanics.