Cotton Incorporated is a sustainability focused industry resource charged with promoting cotton’s benefits and increasing cotton’s market share.

Cotton Incorporated is a sustainability focused industry resource charged with promoting cotton’s benefits and increasing cotton’s market share.

By Rachael S. Davis, Executive Editor

Cary, N.C.-based Cotton Incorporated is a research and promotion not-for-profit charged with the mission to increase the demand and profitability of cotton.

The company — funded by U.S. growers of upland cotton and importers of cotton textile products —was founded in 1970 in response to the rise of synthetic textile fibers and their impact on cotton’s market share. Today, cotton continues to face competition from synthetic fibers, and also faces an increasing threat from man-made cellulosic fibers that are growing in popularity because of their sustainable attributes.

But cotton is the “OG,” or original, sustainable fiber, and arguably, recycled cotton is the most sustainable fiber out there.

Promoting Cotton’s Benefits

Cotton Incorporated maintains its focus on cotton’s desirable attributes in this changing marketplace. “Cot-ton Incorporated recognizes the evolving landscape of the textile industry,” said Mark Messura, senior vice president, Global Supply Chain Marketing. “Our approach to positioning cotton in this competitive environment is multifaceted, focusing on cotton’s inherently natural benefits while embracing sustainability and innovation. Research indicates cotton has improved abrasion resistance compared to other man-made cellulosic fibers. That durable quality makes cotton long lasting.”

“In any comparison of fibers, there are bound to be trade-offs between materials,” noted Dr. Jesse Daystar, vice president of sustainability and chief sustainability officer at Cotton Incorporated. “When selecting materials, durability is among the most crucial factors, and historically, cotton has excelled in this regard. Even after a cotton garment’s initial use, its second and third lives contribute to the sustainability of both the garment and the material.”

Cotton can be reused and repurposed making it an excellent sustain-able choice for textile products. Recycled cotton can be found in apparel, but also in applications such as diapers, wipes, cosmetic and wound care products, insulation materials, product packaging, and more.

“Recycled cotton fibers in new apparel and home textiles can be blended with virgin cotton fibers to create high quality products that meet sustainability and circularity objectives,” Messura noted. “This approach maximizes the lifecycle of cotton products, diverting waste from landfills and reducing environmental impact without compromising the integrity of new cotton products.”

Resource Management

A significant factor in the overall sustainability of a cellulose-based fiber is the thoughtful management of resources. “Land use change and deforestation pose significant challenges for rayon/viscose materials,” Dr. Daystar said. “Recent reports have highlighted concerns that many major producers of man-made cellulose are obtaining their trees from rainforests and other biodiverse regions. In contrast, cotton has not been associated with such land use changes. Increases in cotton production over the years have led to improved yields rather than expanding acreage.”

“Fibers made from wood cellulose are manufactured and do not occur in nature,” Messura added. “We don’t wear trees. Chemical and manufacturing processes are needed to transform cellulose from wood into fibers that can be used in industry. Cotton is given to us by nature as a ready-to-use fiber.

“Grown from the earth, cotton fiber is naturally breathable, comfort-able, soft, absorbent, and hypoallergenic which makes it the fiber of choice for many apparel, home and nontraditional applications,” Messura continued. “It also has many sustainability benefits throughout its circular lifecycle. It is renewable, biodegradable, compostable and recyclable.”

All these properties make cotton the ideal sustainable fiber, but there is always the opportunity to research and improve. This opportunity falls right into Cotton Incorporated’s wheelhouse.

Improving Cotton’s Sustainability Reputation

Sustainability is built into Cotton Incorporated’s ethos from environmentally viable farming solutions to fiber and yarn development, and beyond. The company’s Sustainability Division is focused on improving cotton’s sustainability reputation in a variety of areas. “Ongoing research and communication efforts with stakeholders aim to position cotton at the forefront of sustainable fiber choices for decision-makers,” said Dr. Daystar. “This involves exploring sustainable growing practices, establishing metrics for sustainability, and understanding the full lifecycle of cotton—from its use to its potential for reuse and return to the earth.”

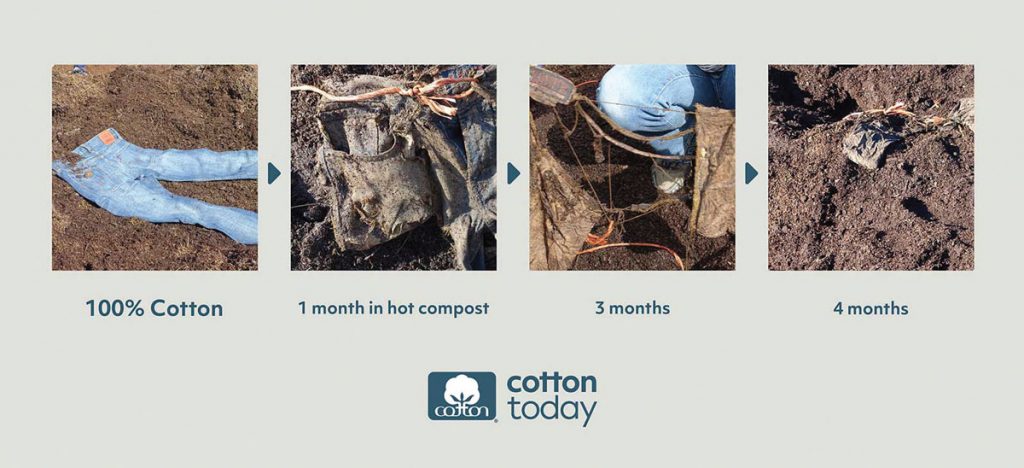

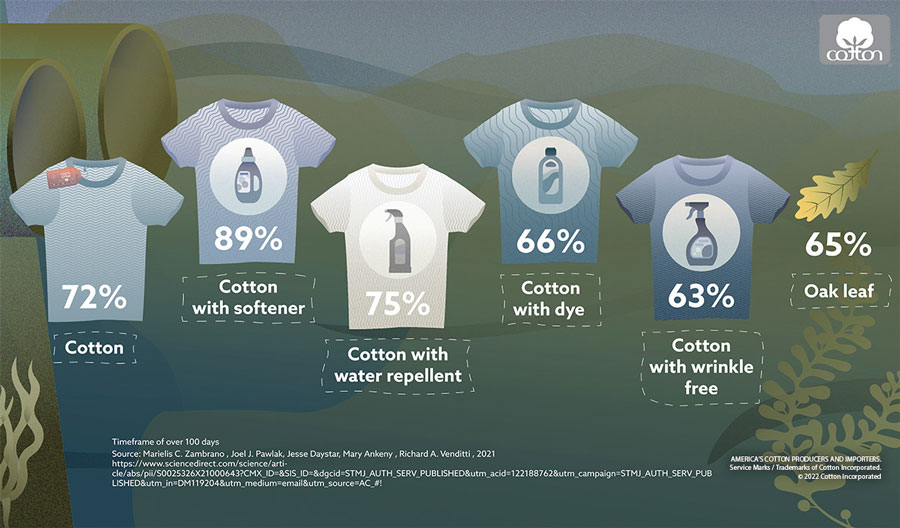

When it comes to biodegradability and composting, Cotton Incorporated recently engaged with a research team at Ithaca, N.Y.-based Cornell University to investigate the compostability of cotton. Published results demonstrate that cotton biodegrades in a variety of conditions including landfill, soil, composting and aquatic. “We’ve also shown that cotton can break down with applied chemistry in different environments,” Dr. Daystar added. “To put it in context, cotton breaks down faster than an oak leaf and toilet paper. As plastic pollution remains a big problem, using natural, biodegradable fibers like cotton is important in combating plastic pollution.”

Dr. Daystar continued: “Composting cotton offers an elegant circular solution with near-term scalability, presenting numerous environmental benefits. The application of composted cotton to cotton fields has the potential to reduce the need for synthetic nutrients, enhance soil carbon levels, and mitigate methane emissions from discarded apparel in landfills.”

Lifecycle Assessment

To address controversy and challenges that currently exist in measuring cotton sustainability, Cotton Incorporated also has teamed with Cascale — formerly known as the Sustainable Apparel Coalition — and the Cotton Expert Methodology Group to establish a common approach to collecting cotton data to model within the Life Cycle Assessment (LCA) framework. “We are completing the first-ever U.S. cotton life cycle assessment,” Dr. Dystar said. “Data from more than 700 cotton producers were collected and used for this study. The study is about to undergo peer critical review from industry experts before being published later this year. Data from this study will be submitted to LCA databases and the Higg index.”

Sustainability Goals, U.S. Cotton Trust Protocol

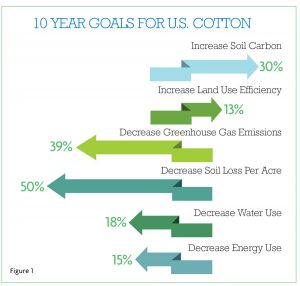

Cotton Incorporated, in conjunction with a sustainability task force and other cotton industry leaders, published 10-Year Sustainability Goals in 2015 for cotton growing to further improve the sustainability of cotton (See Figure 1). “Continuing our commitment, we have invested in research aimed at improving cotton production and cotton sustainability,” Dr. Daystar offered. Improved technologies, management and conservation have resulted in gradual improvements over the past 35 years — including reductions in land, energy and water use; soil loss; and greenhouse gas emissions — but the industry wants to continue such improvements and keep pushing the boundaries. The 10-year goals are based on science-based assessments such as key performance indicators for producing each pound of cotton.

The U.S. Cotton Trust Protocol, a sustainability program for U.S. cotton growers supported by Cotton Incorporated and launched in 2020, will help the industry meet the 10-year goals. The program offers access to full supply chain transparency and science-based field-level verified data, and aims to drive continuous improvement across six key sustain-ability metrics.

“Under the U.S. Cotton Trust Protocol, the Climate Smart Cotton Program is a five-year, collaborative initiative to increase the adoption of climate-smart cotton production practices of reduced/no-tillage, cover crops, and nutrient management,” Dr. Daystar said. “Under this grant, a carbon inset program will be developed. Throughout the project, the expected carbon emissions reductions are over a million metric tons of carbon dioxide.”

Marketing Sustainability

Cotton Incorporated has long participated in consumer marketing programs to promote cotton at the end of the supply chain. Consumers are familiar with its “The Fabric of Our Lives” catchy campaign jingle, which over the years since it was first launched in 1989 has been reimagined and covered by many famous singers including Aaron Neville and Miranda Lambert.

In addition, the trademark Seal of Cotton logo, also widely recognized, celebrated its 50th anniversary last year (See “Cotton Incorporated Celebrates 50 Years Of The Iconic Seal Of Cotton,” TW, July/August 2023).

In today’s era of sustainable textiles and sustainable production, one of Cotton Incorporated’s goals is to ensure consumers understand the benefits of cotton. The good news is that Cotton Incorporated polls have shown that the majority of consumers already see cotton as a sustainable fiber.

“From a recent 2023 global sustainability survey, we know that 70 percent of global consumers say sustainability influences their clothing purchases and the same number of consumers globally — 70 percent — typically check labels for information about the sustainability of a clothing item,” said Kim Kitchings, senior vice president of consumer marketing. “An overwhelming 83 percent of global consumers believe cotton is safe for the environment, more than any other fiber, natural or man-made.”

According to Kitchings, data shows Cotton Incorporated still has an opportunity to further educate the consumer though because 35 percent or fewer are familiar with the terms “traceable,” “circular” and “grown using rengenerative agricultural practices.”

“With these data in mind, our multi-faceted marketing activities educate consumers about the sustainability of cotton in a variety of ways including: two recycling programs — Blue Jeans Go Green™ in the United States and Cotton Lives On™ in the United Kingdom; brand and retailer partnerships that share sustainable facts about cotton; influencer campaigns that educate about cotton as a sustainable, biodegradable fiber; the creation of national youth curriculum; and advertising messaging and public relations activities that help correct misinformation,” Kitchings added. “We keep our message simple, in terms the consumer understands, by highlighting cotton as a natural fiber with a simple call to action — check the label for cotton. Since eight out of 10 consumers recognize the Seal of Cotton and associate it with attributes like durability, sustainability, and quality, we encourage them to look for the Seal of Cotton on products. Today, 82 percent of consumers associate the Seal of Cotton with the term sustainable up from 59 percent in 2016. Now that’s true sustainability — no matter your definition!”

Cotton Incorporated: Industry Resource

Cotton Incorporated is so much more than its sustainability division. Its research and promotion efforts span the cotton supply chain from farm to garment across the globe. The organization is there to help and wants industry players to lean on Cotton Incorporated as a resource. The not-for-profit utilizes its expertise to make better cotton, use cotton better and develop technologies to make better cotton fibers, yarns and fabrics. It also performs market research and collects data in a variety of arenas that support research and marketing both industrially and on the consumer side.

Starting at the field, Cotton Incorporated supports agricultural research to help farmers maximum yields, increase profitability and save costs. Cotton Incorporated works with the U.S. Department of Agriculture, universities and private companies, sponsoring some 400 research projects each year. “We are taking a more holistic approach than before,” said Dr. Ryan Kurtz, vice president, Agricultural and Environmental Research. “We are developing a program that look at all aspects of a growing region because they are all different as far as soil and climate goes and the needs are different.”

The Fiber Competition Division works closely with the U.S. Department of Agriculture (USDA) to classify each bale of cotton across a range of properties including length, length uniformity, strength, thickness, color and elongation. When it comes to fiber competition, this data is invaluable when cotton is competing against very uniform polyester or man-made cellulosic fibers that are cut to very precise staple lengths. The department also offers its Engineered Fiber Selection® (EFS®) software suite to help companies deal with copious amounts of cotton data and make sound financial and quality decisions. The MILLNet™ portion of the software suite is celebrating 40 years in the industry in 2024 (See sidebar).

Product Development & Implementation

As part of its global supply chain marketing strategy, Cotton Incorporated is engineering value into cotton. Some 90,000 square feet of the 120,000-square-foot Cotton Incorporated headquarters building in Cary are dedicated to laboratory space. The organization does not charge for any of the technology it develops. Manufacturers are qualified to use the technologies and then Cotton Incorporated helps connect brands with those companies producing products featuring Cotton Incorporated innovations. Additionally, the brands do not have to carry the Cotton Incorporated product name if they use the technology. “There are many products out in the marketplace featuring Cotton Incorporated technology that do not carry the Cotton Incorporated name,” Messura said. “Brands are free to name and brand a product as they wish to stay inline with their product marketing strategy.”

Cotton Incorporated scientists have developed, and continue to research, functional finishes to help cotton compete with man-made fibers. Some of the latest technologies include:

- ToughCotton™ — which enhances the abrasion resistance of cotton to extend the lifetime of a cotton garment;

- PurePress™ — a non-formaldehyde finish for cotton wovens and knits that improves strength and abrasion resistance as well as wrinkle resistance without compromising the softness of the fabric;

- STORM COTTON™ — a durable water repellent (DWR) finish that confers water resistance for the lifetime of a garment without compromising breathability and comfort;

- TransDry® — a moisture management technology that imparts wicking and fast-drying performance to cotton garments; and

- Natural Stretch™ — a mechanical innovation designed for 100-cotton woven fabrics that provides stretch without the need for spandex.

“Cotton is an innovative and versatile fiber that can be designed and manufactured to outperform competitive fibers,” Messura noted. “Cotton can be designed to repel water, wick moisture and withstand the toughest durability challenges through Cotton Incorporated’s suite of performance technologies.”

Cotton Incorporated’s latest development, RESTech COTTON™, was invented to combat the increasing use of non-cotton fibers in bedding products (See “Soft, Sustainable ZZZs,” TW, November/December 2023). The technology imparts improved softness, moisture management properties and durability to cotton sheeting for a more restful night’s sleep. Cotton’s market share in home furnishings is an area where Cotton Incorporated sees opportunities for growth.

The company’s headquarters location also houses carding and spinning equipment — which covers all the spinning methods — knitting machines, sample weaving machines and a fully equipped dyeing and finishing lab to research, innovate and develop samples to inspire the industry. It’s yearly FABRICAST™ collections, featuring 100-percent cotton and cotton-rich woven and knit fabrics, are produced as a resource to help product development teams, manufacturers and retailers to get the most out of cotton. The collection highlights new yarns, unusual weaves or knit constructions, the latest in dyeing and finishing technologies, and Cotton Incorporated’s performance technologies.

Users may create a free account at cottonworks.com to access fabric innovations, trend forecasts, market and consumer information, technical education, and sustainability information. A new virtual showroom houses digital twins of the physical Fabricast collection styles in 3D and augmented reality. Plans are in the works for some gaming features also.

Beyond apparel and home applications, Cotton Incorporated’s fiber research extends further as the company looks to challenge man-made fibers in other areas such as injection molding and composites. One area of interest is converting cellulose to glucose. Cotton waste such as old garments may be mixed with enzymes to produce glucose that can be used in cosmetic and detergent applications. With sustainability very much at the forefront of Cotton Incorporated’s research and development, that means using the entire plant. Cotton Incorporated is even promoting cotton seed oil to the cooking industry as an alternative to other traditional cooking oils.

Student outreach also is important to Cotton Incorporated (See sidebar).

Global Outlook

Cotton is a global commodity and Cotton Incorporated’s efforts are supported by its global network of offices. The company has a strong presence in Latin America. “Cotton Incorporated continues to be a unifying force for many Latin American textile and apparel companies,” said Jaime Flores Cornejo, senior director of Supply Chain Marketing, Latin America, who is based in Mexico City. “With an extraordinary suite of resources, Cotton Incorporated brings mills, brands and retailers to a common point, to better serve their respective customers through innovation and a sustainable approach to their products. Companies working with Cotton Incorporated find tools to become more competitive. Particularly, in the recent year, Latin American mills have strengthened their export power incorporating cotton performance fabrics, while local brands and retailers have connected

more strongly with the shopper through licensing the Seal of Cotton, incorporating cotton fiber’s sustainable and recycling attributes to their sales message, and adding more education on fashion, technical, and cost-related decisions on sourced fabrics and garments.”

Cotton: Nature’s Ready-To-Use Fiber

Cotton Incorporated’s dedication to the industry hasn’t wavered since its founding in 1970, and if the non-profit has anything to do with it, cot-ton will endure as “The Fabric of Our Lives.” Data-driven studies show cotton to be a responsible, sustainable choice and the natural benefits of cotton are enhanced on a continual basis through Cotton Incorporated’s research and development efforts. The organization also wants the industry to view it as a resource, especially when it comes to data.

“The textile industry today is a lot different than it was years ago, but while we are all navigating a changing industry, Cotton Incorporated continues to understand, research and support all aspects of the business — from the farm to textile innovations and consumer behavior,” Messura said. “That enduring commitment to cotton is the best form of sustainability.”

Cotton In The Curriculum Grant Program

Advances Knowledge Of Cotton At The Wilson College Of Textiles

— TW Special Report

The Cotton in the Curriculum (CIC) Grant Program, a competitive grant program sponsored by Cary, N.C.-based Cotton Incorporated aims to further the understanding and knowledge about cotton among students preparing for careers in the apparel and textile industry. The program has been instrumental in shaping textile design education at NC State’s Wilson College of Textiles, Raleigh, N.C. Through student competitions and experiential learning, the textile design projects funded by this grant program have successfully engaged students in exploring the potential of cotton across various design themes, and fostered a deep understanding of this versatile fiber.

Since 2020, the team of five textile design faculty — comprised of Janie Woodbridge, Dr. Traci Lamar, Dr. Kavita Mathur, Kate Nartker and Dr. Lisa Chapman — have received CIC grants enabling them to incorporate experiential-based curriculums with industry artists, designers and experts, workshops, and field trips. The CIC Grant Program funds have allowed the university to showcase remarkable student projects that highlight the significance of textiles in contemporary design.

For instance, the current project focuses on how craft knowledge influences modern textile industry practices, emphasizing the tactile experience and craftsmanship associated with cotton materials. Similarly, the 2023 project centered on high-performance products for an active lifestyle, reflecting consumers’ desire for both functionality and comfort in their textiles.

Each of the projects funded by the grant encouraged design students to reflect on contemporary industry topics and address them using cotton. The 2022 project focused on sustainability and innovation and delved into circularity in a digital industry. This theme underscored the importance of sustainability in textile design and explored how application of digital textile design and development tools can enhance cotton’s sustainability profile.

In another example, the 2021 project highlighted universal design principles, showcasing cotton’s versatility in creating inclusive and accessible textile products for diverse demographics.

Looking back at the 2020 competition, which focused on heritage and high-performance textiles, students were challenged to reinterpret historic cotton fabrics for modern consumers. This project celebrated cotton’s rich heritage while encouraging students to innovate and meet the demands of contemporary lifestyles.

Through workshops, field trips, and exhibitions, students participating in these projects have gained invaluable hands-on experience and insights into the multifaceted world of cotton in textile design, an experience that would have not been possible without the support of the CIC Grant Program. These projects’ successes lie in their ability to inspire creativity, foster sustainability practices, and equip students with the skills needed to excel in the ever-evolving textile industry, especially in relation to the use of cotton fiber.

The CIC Grant Program stands as a beacon of innovation and education in textile design, shaping future designers who are not only skilled but also conscious of sustainability and consumer needs. By bridging academia with industry through funded projects, this program continues to help us to nurture talent and push boundaries in textile design education in Wilson College of Textiles.

Engineered Fiber Selection® (EFS®):

Engineered Fiber Selection® (EFS®):

MILLNet™ Software Reaches 40th Anniversary

Introduced in 1982 and signing its first two licensees in 1984, Cotton Incorporated’s Engineered Fiber Selection® (EFS®) MILLNet™ software is celebrating 40 years as a trusted resource for cotton bale management. An industry standard for bale management, MILLNet is an array of management tools that allows a mill to select the right cotton for the end-product in question, matching cotton specifications at the lowest raw material cost. MILLNet is key to understanding the value of each bale of cotton based on a standardized set of specifications and in managing copious amounts of cotton data to make the best financial and quality decisions.

“We’re excited to celebrate the 40th anniversary of the first adoption of the EFS MILLNet software and four decades of industry trust in our bale management system,” said Vikki Martin, vice president of Fiber Competition. “Our longest-running licensee has used the system for 38 years to manage cotton processing. That’s a strong indication of the endurance and importance of the EFS® System software.”

In addition to MILLNet, today the EFS software suite also comprises:

- USCROP™, which lets users view HVI® data for USDA classified cotton, which leads to informed buying decisions.

- Cotton Communicator™, which permits cotton merchants and mills to exchange cotton buying and selling information using electronic data exchange and ASCII files.

According to Cotton Incorporated, an estimated 20,000 bales of cotton valued at $7.5 million are processed each day using the EFS MillNet software, and more than 56 million bales have been managed by EFS-licensed mills since 2016. Some 75 percent of these bales were U.S. cotton.

Licensees using the software suite are able to produce a higher quality, more consistent yarn that is stronger and more uniform, according to Cotton Incorporated. The more than 50 global licensees have access to technical support specialists from Cotton Incorporated offices in Cary, N.C., Mexico City and Hong Kong.

“The relationship we build with our licensees is exceedingly critical,” Martin stressed. “The software is tailored to meet each mill’s unique requirements, a process that begins with understanding their operational intricacies. Our commitment goes beyond providing software. We offer personalized customer support and access to a wide range of services from Cotton Incorporated, including fiber quality, economic information, and fiber processing technical support. In many cases, these relationships span decades, evolving to a point where our licensees become like an extension of our division.”

March/April 2024