Lightning Risks on Mining Operations

Over the past several years those who take a passing interest to my regular musings here on Linkedin will know of my continuing remonstrations as to the plethora of undiagnosed risks that affect workplace safety, and that can additionally impact on operational productivity.

Lightning initiated tyre pyrolysis resulting in hi-potential tyre explosions, has been a regular subject matter raised, a hazard which has been a regular visitor to Australian mining operations, yet despite the wide recognition by the regulators and the industry in general, there are still gaping holes in lightning management plans that would cover off and cater to such risks.

I suggest the vast majority of Australian mining operations have not sufficiently catered to this risk, and to those who would suggest existing lightning management plan deals with this via procedures and exclusion areas, can I further suggest that administrative controls alone offer no useful solution, although they are a key part of the solution.

The reality is that there is a lottery being played throughout hundreds of Australian operations within the mining sector, where the demonstrated lack of understanding from the engineering design phase, through to the health and safety operational oversight, place many workgroups, as well as operational productivity, at a significant risk, where the appropriate controls are either not known, not understood, or are simply dismissed through poor risk assessment practices.

Whilst there has been many recent lightning initiated tyre fires and explosions, the Anglocoal Drayton incident from Nov 2007 highlights the potential severity of such a hazard, where a lightning strike had attached to an HME parked up at a Go Line near the heavy fitters workshop and administration buildings.

CIRCUMSTANCES

Three (3) tyres were blown off the truck between 2 to 5 minutes after the lightning strike.

Two tyres exploded (position 1 and 3 tyres) on the driver’s side of the truck, sending debris several hundred mtrs from the vehicle causing extensive damage to the HME and other nearby heavy mobile equipment.

- A 1600 kg wheel assembly was ejected approx. 100 mtr's away from the truck.

- A 250 kg wheel flange was blown off landing nearly 300 mtr's away on a stockpile

- The pressure release estimated to be > 1000 psi caused significant damage to the operator’s cabin, nearby plant, and shattering window glass up to 230 mtrs from the truck.

- Tires were ejected finishing between 50 -60 mtr's away from the truck.

DPI NSW Mine Safety Report No: SA08-03 details this incident in greater detail for those who may wish to investigate the incident further, although the point I am wishing to make in this post relates more to:

- the proximity of HME to populated workplace areas

- the orientation of the HME that would focus a pressure wave towards heavily populated workplace areas.

- the proximity and orientation of HME go lines to crib huts

- the exposure of trafficable accessways between go line park up and nearby facilities

- the proximity and orientation of HME park ups to maintenance workshops

- the proximity and orientation of HME park ups to primary traffic thoroughfares.

Any lightning management plan MUST consider these, along with other related issues, that would cater to the unintended consequence associated with the random ejection of debris and a massive pressure release upon nearby sensitive areas.

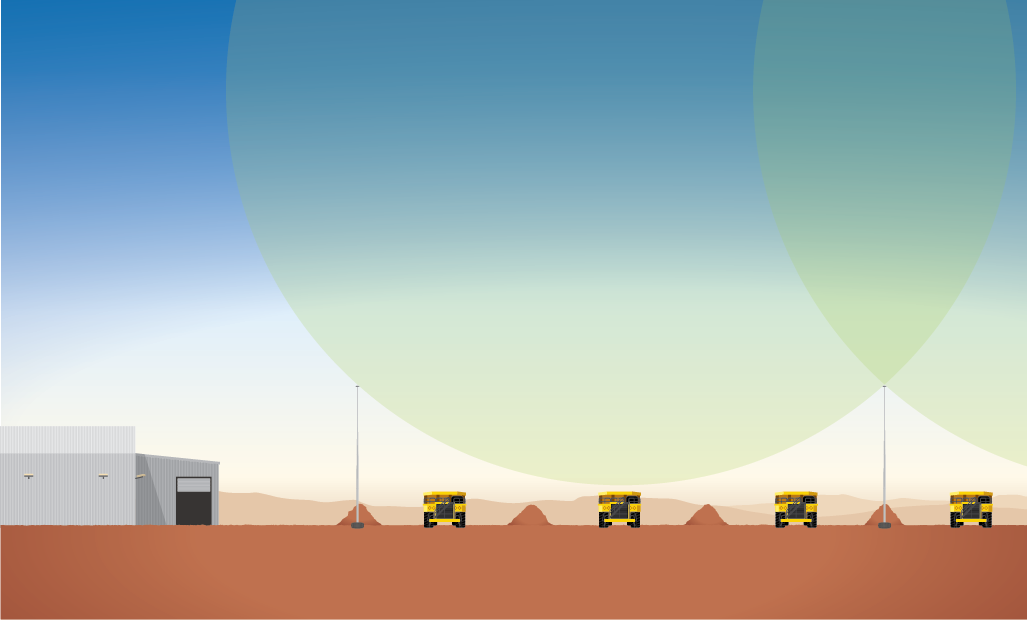

Image courtesy of Lightningman Pty Ltd Copyright

The above graphic highlights a typical control which we suggest should form a mandatory design consideration in any go line/park up area, and simply involves the provision of freestanding lightning protection masts that provide a protective area coverage to the HME, that would sufficiently offer lightning protection to the go line/ park up areas, and thereby reduce the probability that any negative event could lead to unnecessary consequences.

The current Australian lightning protection standard AS1768 is currently in revision, to which a new Appendix M is to be included that will specifically cater to lightning risks on mines. We understand that the issue of tyre pyrolysis and tire fires/ explosions forms an integral aspect of this new Appendix M.

Lightningman Pty Ltd has a long and extensive experience both here in Australia, and around the world, in understanding, and dealing with lightning related risks associated with higher risk mining operations. We can advise, design, and supply the correct risk mitigation solutions.

Do your operations have their lottery ticket?

Grant Kirkby- Lightningman 0419 106 607

EQUIPMENT FINANCE 🌟 TRUCK FINANCE 🌟 CAR FINANCE 🌟 CARAVAN FINANCE 🌟 MOTORBIKE FINANCE 🌟 BOAT FINANCE 🌟 PERSONAL FINANCE 🌟

3yI'll have to make some changes after reading this Grant, thanks for sharing.

Decarbonisation | Project Management | Major Projects

3yBrilliant article.

Lightning Technologist-Lightningman Pty Ltd t/as Lightning and Surge Technologies Specialist in lightning risk mitigation

3yhttps://safetowork.com.au/lightning-strike-sparks-tyre-explosion/ Two Workers injured at crib hut