Laser-based welding has several important advantages for plastics compared with conventional contact methods in numerous applications, including medical devices and automotive parts.

Jonathan Magee

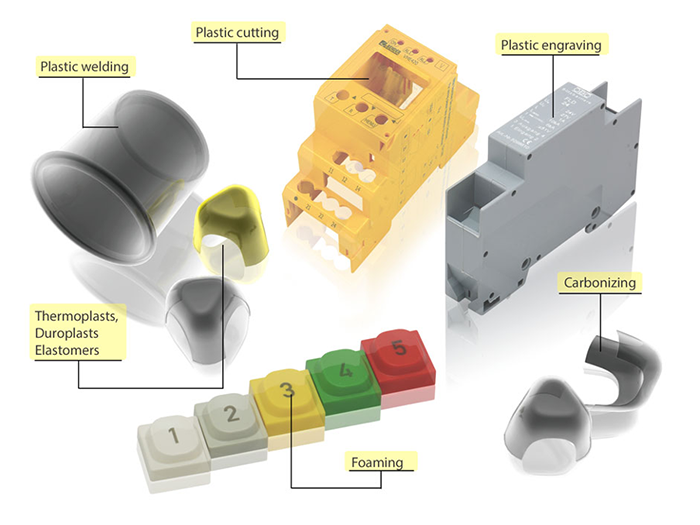

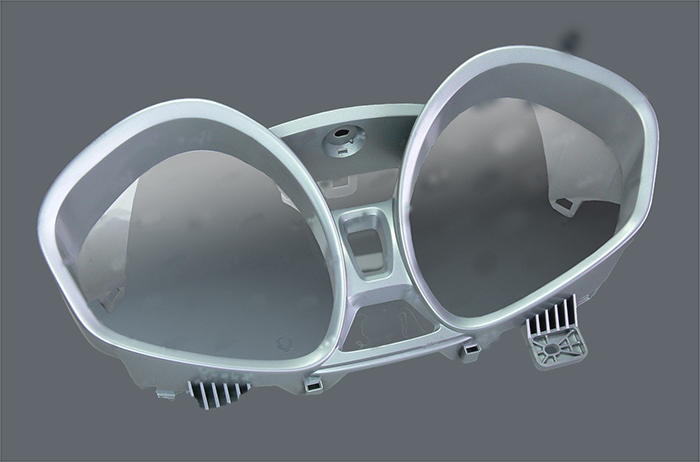

Industrial lasers are used to process engineering plastics across many markets. Some examples of the common processes are shown in Figure 1, including laser marking, cutting, and welding. Well-recognized markets in the field of laser plastics welding include automotive (Figure 2) and medical devices.

|

Figure 1. Laser processing of plastics. |

|

Figure 2. Automobile speedometer clock faceplate laser welded to housing. |

The rationale for laser plastic welding

Laser-based welding has several important advantages for plastics compared with conventional contact methods. Laser welding is a non-contact process at the point of welding that generally takes place at the interface of overlapped parts. Consequently, the weld zone is encapsulated. This results in an aesthetically pleasing weld, which is sterile and does not contaminate the surface of the parts being joined. It seems a little counterintuitive that parts already in contact with each other can be welded together, from the top down, without disturbance to their outer surfaces. With conventional plastic welding techniques, such as ultrasonic or hot stamping, contact with the outer surfaces of the parts to be welded together is inevitable. Non-contact laser plastic welding works on the principle of partial transmission, reflection, scattering, and absorption of laser light within the polymer chains being joined. By careful selection of the plastics and the laser’s optical properties, sufficient heat is generated at targeted locations to melt and fuse together the materials.

The design of a laser-welding process should be established early in product development. Attempting to retrofit a laser-welding process onto plastic products not originally designed for laser welding can work sometimes. However, adopting design for laser manufacture principles at an early stage of plastic product development will greatly reduce manufacturability issues later.

Design considerations for laser plastic welding

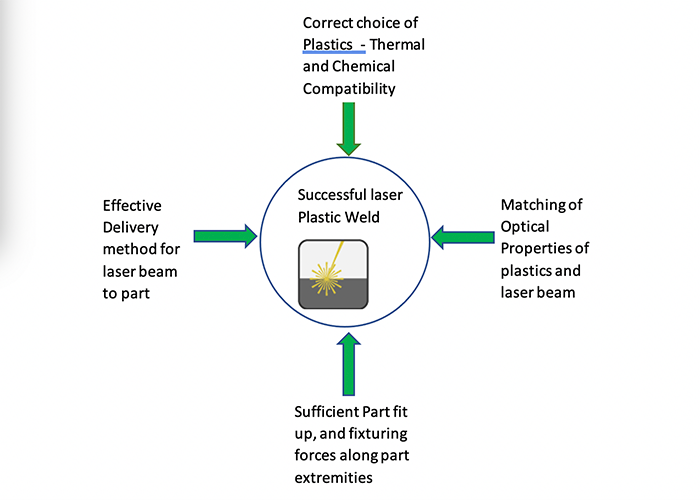

Plastic products have mechanical, geometrical, thermal, and optical properties among others (Figure 3). At a fundamental level, the laser weldability of plastic assemblies can broadly be determined by the following:

Are the chosen materials compatible? Compatibility refers to the melting temperatures and chemical, mechanical, geometrical, and optical properties of both plastic parts to be welded.

Can the laser beam be transmitted through the top-layer material efficiently to reach the joint interface, and can the bottom-layer material absorb the laser beam to create heat where it’s needed?

Can the parts be held together properly during the welding process, and can the force applied be controlled? Does the geometry of the parts result in a good fit between the parts without gaps?

Can the laser beam delivered to the parts be distributed and controlled in an effective manner given the geometry?

|

Figure 3. Design considerations for laser plastic welding. |

Thermal and chemical compatibility

Plastics melt and decompose at much lower temperatures than metals. Typical melting temperatures of engineering plastics are around 250° C. There are some plastics with much higher melting temperatures, such as polyetheretherketone (PEEK), which is in the 350° to 400° C range. Close compatibility of melting temperatures will assist mixing of the weld pool and improve mechanical strength on re-solidification. Certain combinations of plastics that are relatively closely matched on melting temperatures are good candidates for plastic welding. The chemical composition of the plastic is also a factor. For example, attempting to weld high-density polyethylene (HDPE) to polypropylene (PP) will not be successful, but it is possible to weld low-density polyethylene (LDPE) to polypropylene (PP), even though polyethylenes are within the same family. Careful consideration must be given to the material combinations.

Matching optical properties

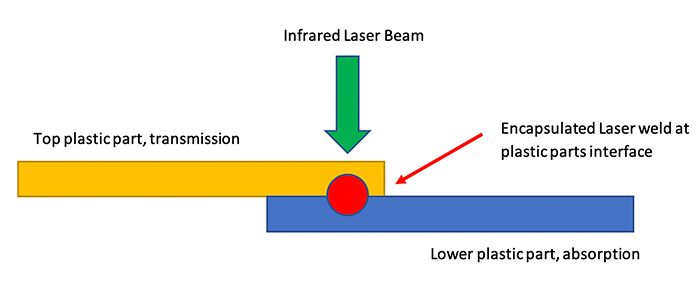

Lasers in materials processing generally emit a light beam at one wavelength or a very narrow wavelength bandwidth. Unlike natural light, the laser beam is coherent and focusable. Near-infrared and infrared wavelengths are most widely used in plastics welding from 800 nm to 2 µm, often with high-power diode lasers. These wavelengths are longer than wavelengths visible to the human eye, such as green, which is 532 nm in the visible spectrum, and red, which is 635 nm. Using the 800- to 2000-nm wavelengths, the plastics to be welded must exhibit some degree of transmission and absorption in this range. Plastics are to some degree semicrystalline structures and have amorphous and crystalline phases. Differences in the refractive index between the amorphous and crystalline phases within a plastic cause light scattering and reflection when a laser beam impinges on them, in addition to the necessary transmission and absorption. This can be beneficial or a hindrance for laser welding, depending on the level of these effects. Design combinations of these properties help to achieve transmission of the laser beam through the top plastic part and absorption in the lower part (Figure 4). Sometimes additives are included in the masterbatch to make polymers absorb laser light. It should be considered at the design stage whether additives are acceptable in the product — would the medical device made with this plastic receive FDA clearance, for example?

The level of glass fibers in certain plastics such as polyamide (PA-66), commonly referred to as nylon, can affect the transmission of light through them, especially at higher levels of glass-fiber concentration where transmission is lower. A frequent question regarding plastics is, which colors can be welded together? There is no simple answer: Many combinations are possible, even same color materials such as clear to clear, white to white, and black to black can be joined with careful design of the composition. Even though visible light does not transmit through colored plastics, this can be completely opposite for a single laser wavelength.

|

Figure 4. Idealized light transmission and absorption in laser plastic welding. |

Sufficient part fit up and fixturing forces along part extremities

Designers must always seek to ensure that the parts are molded in geometries that lend themselves to laser plastic welding through good fit up of the assembly components and an accessible joint. Laser welding is not good at transmitting heat across air gaps and it is important that the component parts of a joint be in contact. Lap weld configurations achieve this. Butt welds are possible in some instances and depend heavily on how the laser beam is applied to the weld seam and on the part tolerances coming off the molding machine producing the plastic parts. Welding lids to containers is an example of good part fit up.

Downward force during the welding process is essential for certain complex parts, especially large ones where it is difficult to achieve good fit up naturally all the way around their boundaries. The clamping force can be generated by servo drives, or through the use of pneumatic clamping. There is a collapse force for plastic welding, which governs how much force the hot and melting plastic can withstand before it starts to significantly deform, and how much force is necessary to push the parts together when molten. Often force-displacement sensors are integrated into laser plastic welding tooling to monitor and control the force applied to the components during the welding cycle.

Effective distribution and control of laser-generated heat

There are several methods for laser-beam delivery to the workpiece in laser welding. The use of cartesian axes systems, where there is relative movement between a fixed laser plastic welding head and an XYZR table motion system, is one example. These devices may not result in uniform heating of large parts due to the acceleration required at start and stop points, and around changes of direction. However, this method is flexible as the laser path can be generated through CAD data. The use of high-speed galvo scanning heads allows extremely fast movement of the laser beam, at up to 10 m/s. Scanning around a weld seam at very high speed with sufficient power allows an almost instantaneous heating of the entire welding seam from one end to the other. This reduces the effects of simultaneous heating and cooling that cartesian axes systems create.

Another less flexible method is to laser illuminate the parts through a mask. In this case, the mask aperture takes the shape of the required welded seam but must be manufactured each time there is a change of design. Occasionally, specialized laser lenses are employed, which yield a line focus that provides a stitch weld along a defined length. Controlling the optical power may be required during the process, which can also be achieved with pyrometers measuring the workpiece temperature during welding and feeding this information back to a power-control loop in the laser controller.

Summary

There are many interdependencies in laser plastic welding, and significant engineering in designing a solution for complex parts and exotic materials. The uptake of laser plastic welding in industry is impressive, with diverse high-volume products from auto light assemblies to ink jet printer cartridges routinely laser plastic welded.

This article set out to explain some of the basic considerations that must be taken into account when laser welding plastics. Most importantly, the product itself must be designed with laser welding in mind — that’s why product design and process development teams should adopt a collaborative approach early in the product design and development phases with their customers, recognizing the aforementioned points. The mold tools for producing complex plastic products are very expensive to manufacture, and tool designers must be aware about design for manufacture issues around laser welding before finalizing a mold tool design. This will ensure that the part geometries coming off the mold tools can be subsequently laser welded.

About the author

Jonathan Magee is Managing Director, ACSYS Lasertechnik UK Ltd., Coventry, UK.

About the Author(s)

You May Also Like