Hawaiian Students 3D Print Molds for Local Chocolate Shop

As part of a new 3D printing project, a group of students from the Department of Mechanical Engineering at the University of Hawaii recently teamed up with a local chocolate shop. The goal of the collaboration of these students and the Choco le’a in Manoa, was to create custom chocolate molds by using 3D printing technologies.

Since the day the food industry discovered the abundance of benefits additive manufacturing has to offer, new projects have rapidly increased and there seems to be no end in sight. But while most new projects focus primarily on the production of food itself, the possibilities offered by additive manufacturing in terms of tools that support production are at least as versatile and advantageous. Because of that, a group of Students in Manao, Hawaii got the idea for a new project during an upper-level mechanical engineering course. They focused on the manufacturing of 3D printed molds, which would, soon as finished, be used by local Choloate store Choco le’a to produce a new chocolate bar design.

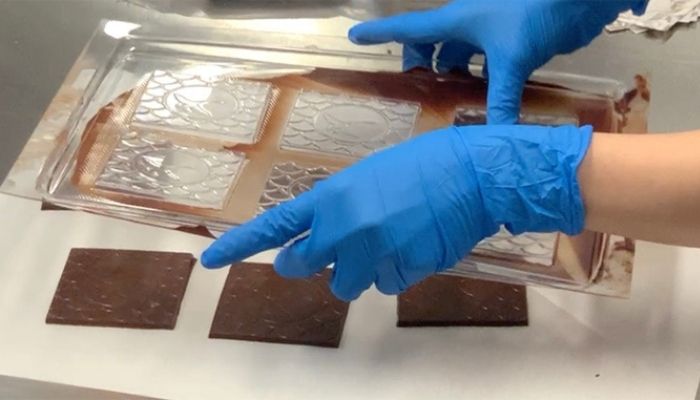

The 3D printed mold (photo credits: University of Hawaii)

The group of engineering students, who were acting under the supervision of Assistant Professor Tyler Ray, first got in contact with the owner of Choco le’a Erin Kanno Uehara. Uehara, a University of Hawaii graduate herself, shared her expertise in the production of chocolate by giving them a tour through her shop and also explained the challenges that her business had in the past and how difficult it was to find the right molds at a low cost. Following that, they shared ideas on how the project would be completed in the best, possible way and what steps would be necessary to make it a success. For the production of the molds, the students used food-safe materials, as well as a high-tech 3D printer and fabrication equipment in the UH Mānoa Department of Mechanical Engineering’s laboratory.

The finished molds were soon presented by the team, and Erin Kanno Uehara was more than happy with the results, “At Choco leʻa, we use chocolates as a way to connect with others and it was an honor to be able to do it right here in our own community,” she said. “A conversation with a chocolate friend led to an opportunity where together we could really ‘Bring peace to our world, one chocolate at a time.’ On behalf of my entire team, we are so grateful to have shared this collaborative experience to grow together. I hope more businesses and schools will partner up because we can all learn a lot from each other! We thank Mahalo Professor Ray and the mechanical engineering students for your exceptional contribution!”

The team behind the project (photo credits: University of Hawaii)

Helping the Community

The project, while presenting a low-cost and sustainable alternative to traditional production methods, also shows a great way to give the smaller communities a chance to help themselves by letting solutions be produced in locally instead of having to order and export from overseas, as this great example of Hawaii, a group of smaller islands located far away in an isolated area in the Pacific Ocean, shows. Normally, due to the lack of production companies close by, smaller stores like Choco le’a’s only option would be to order from the far away mainland, which would make the process time-consuming and shipping expensive. Senior mechanical engineering major Kendall Lorenzo, who was one of the Students working on the project, stated, “Honestly, it feels really good; it feels amazing. Never would I have thought that I would be using my skills to benefit the community. But that’s the heartwarming part of this entire project. I’m hoping that I can use the skills that we learn at UH to benefit more business, more companies, and help them solve the problems that they have.” To find out more about Choco le’a, visit the store’s website, HERE.

What do you think of the 3D printed chocolate molds? Let us know in a comment below or on our Linkedin, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: Choco le’a

Great Article!

What a great project-based learning experience!

I was just wondering what food-safe materials were used? As far as I know, this is the most critical factor and for a long time a reason why 3D-printed molds couldn’t be used in the food industry.