(above: click to listen to the Podcast above or on Spotify – or read the transcript below)

Do you see Turkey as having a considerable interest in COP26?

HB: Yes absolutely, Turkey did stand on the sidelines for a long time, they hadn’t ratified the Paris Accord but actually they put it through Parliament right before COP and also they made a commitment to Net Zero by 2053 which I think is very significant. And now what has to happen is that the NDCs have to match that, they have to basically lay out the timelines and programme and infrastructure developments to get there. [Note: Nationally Determined Contributions or intended NDCs are non-binding national plans highlighting climate actions, including targets for greenhouse gas reductions]

So I think Turkey will become much more proactive, you have to think of it as something they have to do because Europe is our main market and Europe with the Green Deal has made it very clear that they will differentiate between goods and services coming from origins which are not actually in line with fighting climate change. I think you will see trade partners of the EU very quickly aligning themselves with policy and Turkey’s definitely one of those.

Is Arcelik delivering on fighting climate change as well?

HB: Absolutely, Europe is 45% of our business, Turkey is 25% of our business, so if you think of it along those lines, we are very much not only in line but we lead the charge in energy efficiency, so we have as I spoke on the panel, been basically as a company taking sustainability as a business model, more than something that you have to do. So we decided a long time ago we were going to differentiate with our global competitors and really make the core of our existence around sustainability which means we have the most energy efficient products, we use the least amount of energy where we can in our production processes, also materials, and we don’t do this just in Europe where regulation requires it, we do this everywhere. More than 50% of our sales today comes from highly energy efficient appliances and we’re rapidly increasing this and by 2030 we’re looking to halve our Scope 3 emissions which are from our appliances. [Note: Scope 3 Emissions, are what an organisation is responsible for indirectly up and down its value chain]

So you can say that we’ve taken a leadership position, and this is not just us saying it, we lead the Dow Jones sustainability Index for the past two years in a row and we have become carbon neutral which is a big achievement without buying carbon credits. You have to distinguish between companies who say they are carbon neutral by buying credits and companies which actually reduce their emissions by creating carbon credits themselves in their own processes. I think change is happening in the industry as well and I’m just proud of being part of the leadership team which is leading it.

For efficiency in your production processes are you looking at products such as green steel?

HB: We are but that kind of transition has to happen slowly, we use steel from many different sources for us to simply switch to a European manufacturer which has been subsidised to go to greener sources and still significantly more expensive is very difficult so what has to happen I think, the steel industry needs to be incentivised everywhere to go clean, Europe has done this and other markets will follow. This was one of the big issues with Turkey also but we will see in Roadmap to Net Zero how they transform the steel industry but to answer your question shortly, we use Green Steel and we use other steel and to transition out of that we will have to actually transition and transform the steel industry itself first, because there simply isn’t enough green steel in the world if we all want to use green steel.

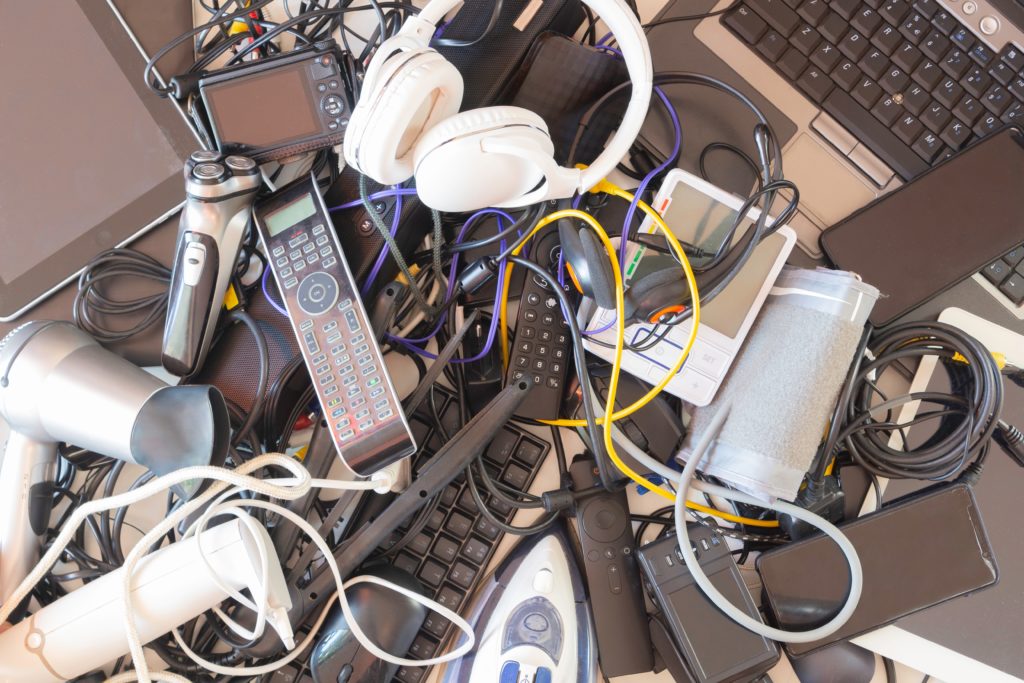

One of the criticisms in the UK and it’s across industry in terms of products, is end of life. There’s a move for products to have longer life, and they should be designed for repair and reuse. Would it be something you adopt as a manufacturer, the long-term life of the product?

HB: I’m all for it by the way, I hate products that you can’t repair, as someone who really dislikes waste, I find it unacceptable. In appliances it’s a little bit different, because the technology improves so much in terms of efficiency I think the benefit of end of lifing a product and replacing it with a much more efficient one, in terms of climate and the planet is a much better solution. So I do believe in repairability, I do believe in modularity and life of products but I also think in energy consuming product groups, I think we should be ready to replace it with newer ones which consume far less energy. Then the question becomes of course, ‘what do you do with the old product?’

What do we do with the old product. Is Beko, Grundig and Arcelik at the top level, are you involved in the WEEE recycling systems in Europe and the UK?

HB: We are, by regulation we have to be in all the markets we operate, but I think the biggest difference is that in markets where we can’t find recycling facilities we are building our own. In Turkey I gave the example earlier on the panel, essentially we have had to build our own recycling plant, a giant plant, which has recycled more than 1.5 million appliances because we simply couldn’t find anyone else to do it. Ideally we’d like to find other people to do it but where we can’t we build our own plants. What we’re trying to do is replace old appliances with new ones so reducing the consumption of Scope 3 energy and emissions which is part of our target to get to Net Zero and we’ve committed to 2030 and a net 50% reduction in Scope 3 emissions, which is emissions caused by the appliance when they’re used by the customer. So if I can get an old fridge out of your kitchen and put a new fridge in there that consumes 60% less power, then I’m actually doing a much, much better favour to the planet than I am by trying to use the old one another 10 years. But we take the old one and recycle it, and put that material back into the market as well.

I think the sector in the UK will find that very interesting because principally the message is, if products are more efficient it may not make sense to hang on to them for ever. How do you see COP26 generally? Are you optimistic, you’re wearing the 1.5% badge, what’s your overall take on COP so far?

HB: More than I expected, the agreement on methane is very significant as you know methane traps heat more than 80 times more than carbon dioxide and the commitment to reduce it by 30% is now signed, it was 80 yesterday and now 105 countries. That’s very very significant. Also there has been other commitments by governments about transitioning away from coal, and we heard from the head of the International Energy Agency, a good friend Fatih Birol, that when he crunches all the numbers and they do that really well at the International Energy Agency, he said we’re looking at a 1.8 degree warming for the world at the moment and that’s down from 2.1 last week, so that’s a success, I think it’s a huge success. But, is it enough, no, for that to happen, action has to start today and much deeper commitments need to be made.

Subscribe for free