Researchers at Pakistan's U.S. Pakistan Center for Advanced Studies in Energy (USPCASE) and the National University of Sciences & Technology (NUST) have developed a new passive cooling technique for PV modules, based on rectangular aluminium fins.

The scientists said they utilized hollow rectangular fins instead of more commonly used solid rectangular bars as they wanted to prevent the weight of the modified PV panel rising. “The hollow rectangular shape of [the] fins, with open ends, also provides the air flow channel, which can ultimately increase the cooling effect,” the researchers also explained.

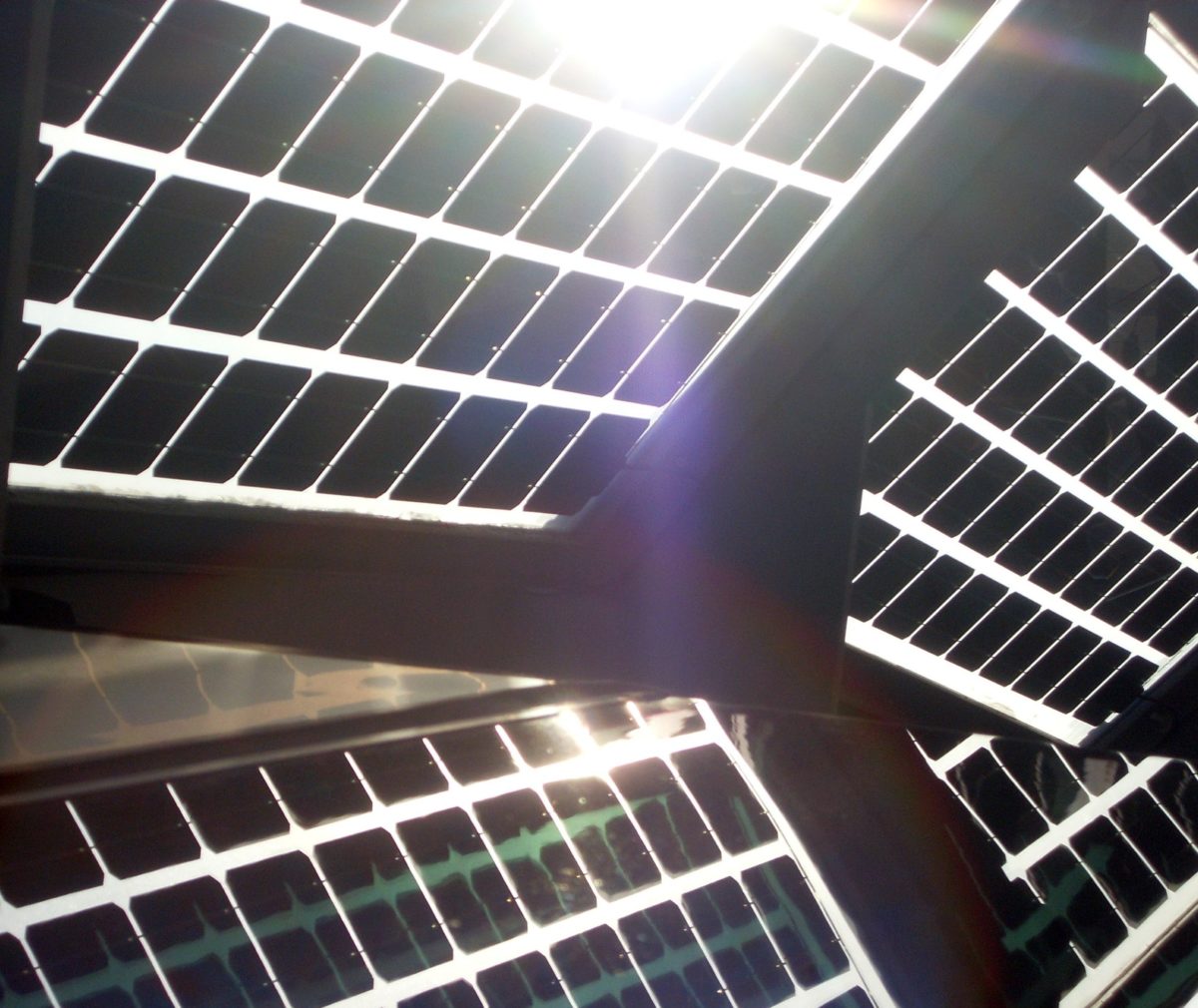

The new technique was tested on a PV system based on two 10 W monocrystalline panels with a weight of 1kg each, one equipped with the rectangular fins and one without them. The array is located at the USPCASE, in Islamabad, with temperatures ranging during daytime from 19.5 degrees Celsius to 26.4 degrees Celsius. Average global horizontal irradiance during the experiment days was 570 W/m2 with a maximum value of 718 W/m2 at around 1 p.m.

The panels used in the PV array have an efficiency of 15.3%, a maximum voltage of 18 V and an open-circuit voltage of 21.24 V. The eight aluminum fins applied to the rear side of the finned panel have a length of 230mm, a wall thickness of 1.9mm, and an annular area of 161.29mm2.

“All tubes are connected to the rectangular strips with a spacing of 25.4mm, which provided a frame-like structure,” the academics explained. “The frame is attached to the back side of the PV module, as a heat sink, using self-tapping bolts and rectangular strips.”

Popular content

The measurements were taken through temperature data loggers, a multimeter, a pyranometer, and an anemometer. “The results obtained from experiments demonstrated that the attached fins reduced the average temperature of the front and rear surfaces up to 8.97% and 8.41%, respectively,” the Pakistani group stated. “The cooling effect produced due to fins, improved the open circuit voltage up to 12.97% and the electrical output efficiency up to 2.08%.”

The adoption of the fins would increase the cost of a module by around $0.20 per W, according to the scientists. The total weight of the aluminum applied to the module is 0.6kg and its cost was $2.33, while the cost of screws and washers was $1.08. “The total cost of the prototype fabrication for thermal management in this study is $2.96 for the PV area of 0.0929m2.”

The new technique is described in the paper Thermal management of solar PV module by using hollow rectangular aluminum fins, published in the Journal of Renewable and Sustainable Energy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.