Stanford alkali metal-chlorine battery stores six times more energy

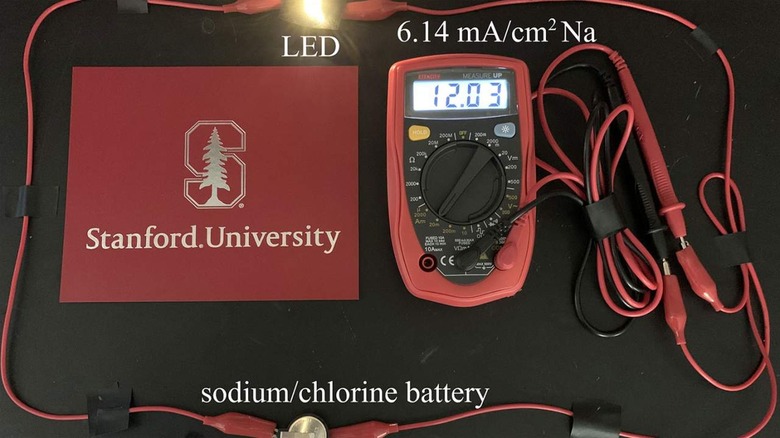

Researchers at Stanford University have lead a team that created a new type of battery they say can store six times more energy than current state-of-the-art batteries. Stanford and a team of international researchers developed a new battery called alkali metal-chlorine batteries and recently published a paper outlining their breakthrough. The new type of battery has the potential to allow devices like cell phones and other gadgets to be charged weekly instead of daily.

The new battery chemistry might also be used to enable electric vehicles to drive six times further before recharging. That would mean an electric vehicle able to drive 200 miles per charge day could drive up to 1200 miles per charge using the new alkali metal-chlorine battery. The new battery chemistry utilizes a process of converting sodium chloride or lithium chloride to chlorine.

A critical aspect is that the conversion process is reversible. Electrons travel from one side of the battery to the other as the battery discharges and travel the opposite direction when the battery is recharging. The battery breakthrough wasn't what the researchers were attempting to do when they began the project. The team didn't begin with the goal of creating rechargeable sodium and lithium-chlorine batteries. Rather, their goal was to improve existing battery technology using thionyl chloride.

Thionyl chloride is one of the main ingredients in popular single-use batteries that were first invented in the 70s. One of the experiments used chlorine and sodium chloride, and researchers discovered the conversion of one chemical to another was stabilized, resulting in rechargeability. The researchers didn't believe this was possible, and it took them a year to discover the underlying process allowing it to work.

Eventually, the team discovered the carbon material had a nanoporous structure filled with extremely small pores. The hollow spheres soaked up chlorine molecules like a sponge and stored them for later conversion to salt inside the micropores. So far, the team has achieved 1200 milliamp hours per gram of positive electrode material. Compare that to the 200 milliamps hours per gram of current commercial lithium-ion batteries, and the massive gain is plain to see.