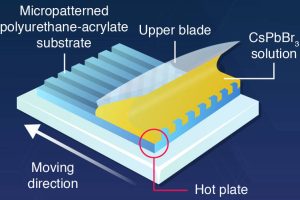

Slot-die coating is a liquid process that “involves continuously and precisely forcing an ink through a narrow slit that is moved across the substrate to form a continuous film,” said post-doc Anand Subbiah. “This high-throughput technique would allow for roll-to-roll fabrication, similar to printing newspapers.”

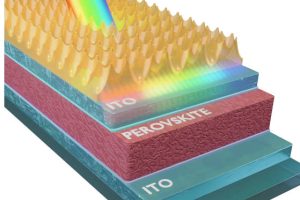

Part of the work required creating an ink suited to the technique, adding a surfactant to the perovskite ink so that it could coat the hydrophobic PTAA (poly(triarylamine)) transport layer, and switching to a lower boiling point solvent to reducing ink drying time without adding process steps.

“The development of scalable deposition techniques for perovskite solar cells is essential to bring this technology from the research labs to the market,” said fellow researcher Stefaan De Wolf. “Our next steps are making large-area devices and modules, and testing their stability in the lab and the outdoors, while continuing to improve performance.”

‘High-performance perovskite single-junction and textured Perovskite/silicon tandem solar cells via slot-die-coating‘, published by the ACS, describes the work in detail and is available in full without payment.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News