- Europe's planned M10 engine continues testing, and the thrust chamber just passed.

- 3D printing has changed rocket development by greatly reducing upfront manufacturing time.

- The new engine uses less environmentally impactful and more sustainable liquid fuels.

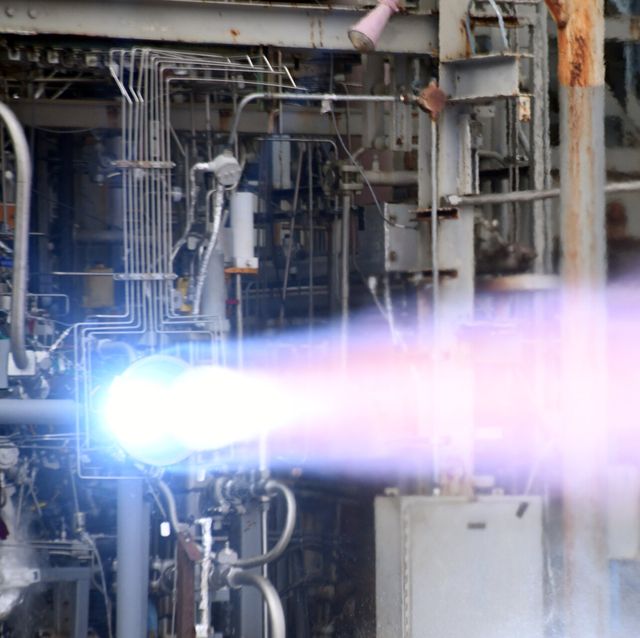

The European Space Agency’s (ESA) Vega launcher project has passed a milestone, with a successful sustained heat test on its new 3D-printed thrust chamber. The new part belongs to Vega’s M10 engine, which the ESA hopes to put into space beginning in 2025.

As part of a “hot fire” test, the engine was fired 19 times for a combined 450 seconds. This kind of test mimics the most challenging conditions a system might face during launch so scientists can identify any weaknesses and help shore them up as development continues. Watch it here:

For the ESA, Vega is a semi-privatized project, because a commercial service actually launches the rockets. Indeed, like NASA, the boundaries between private and public development have blurred in recent decades. Now, the Vega team is working on a next-generation engine it calls M10. The engine runs on liquid oxygen and liquid methane, which is an environmental improvement over the solid aluminum and ammonia the current launch assembly uses.

“M10 will improve propulsion efficiency and environmental sustainability by reducing emissions and combustion waste thereby increasing the competitiveness of European small launchers and lowering their cost,” the ESA said in a statement. Not only is this piece 3D-printed, but it’s also been scaled up over time beginning with the smallest initial model in 2018. After each model is printed, it’s tested using technologies like ultrasound to make sure it’s structurally sound, and then it’s subjected to the normal battery of tests.

The ESA says the engine performed well in the tests, and it hopes to test the fully assembled development model of the engine later in 2020. These tests are really, well, tests in the truest experimental sense—rather than a foregone conclusion that parts and assemblies will perform fine, scientists are prepared for problems and learn a great deal even from failed tests. But there’s a gulf between a catastrophic system-wide failure and something caused by a small leak or loose seal.

Vega has launched over a dozen times from the ESA’s launch pad in the coastal South American territory of French Guiana, which is sandwiched between Suriname and Brazil and reports back to France the same way any mainland French territory does, unlike an autonomous territory like French Polynesia.

The development of the M10 engine represents ESA’s commitment to the future, the agency says. And it’s true that many organizations are using 3D printing to make changes to the way rockets are designed, tested, and built. The ESA says it can build more complicated designs in an overall more agile process by using 3D printing, which removes the need for special manufacturing of machine parts, die casts, and more. When development will still take five more years, maybe there’s no time to lose.

Caroline Delbert is a writer, avid reader, and contributing editor at Pop Mech. She's also an enthusiast of just about everything. Her favorite topics include nuclear energy, cosmology, math of everyday things, and the philosophy of it all.