GM updates post-crash inspection, repair requirements for auto body shops

By onAnnouncements | Business Practices | Repair Operations | Technology

General Motors announced Thursday it responded to feedback about its post-collision safety inspection and replacement requirements with revised guidance on when certain work became necessary presented in a more technician-friendly format.

GM personnel worked for more than a year on the new “Repairs and Inspections Required After a Collision” document (No. 5807146) and incorporated it into the automaker’s OEM repair procedures in April. GM also published it on the free, public GenuineGMParts.com technical information portal in May. And GM wholesale dealer channel collision manager John Eck publicized it to the industry during a VeriFacts Guild 21 call Thursday.

“This document replaces the old document that we had,” Eck said.

The instructions would be accessible within individual 2021-22 vehicles’ OEM repair procedures, according to Eck. (Just search for the word “inspection,” he suggested.) It would be reflected within the individual repair procedures posted for all future vehicles, and GM will also work to tie it into service information for the prior 10 model years’ most popular vehicles, he said.

However, Eck said the document also exists and serves as a standalone GM directive “for all GM vehicles … past, current and going forward.” Shops should follow it regardless of whether the automaker had tied it into a particular model’s specific OEM procedures, he said.

Eck used the example of a 1980 Buick Skylark: GM wasn’t going to rewrite the OEM procedures on the 40-year-old vehicle. But “Repairs and Inspections Required After a Collision” exists as a standalone GM technical document and would apply to that Skylark anyway, he said.

Revised guidance, format

GM’s old inspection guidance presented the collision industry with “a pretty long laundry list of things to inspect and/or replace” following “‘any collision,'” Eck said. It didn’t take severity or technology into account, and some of the operations described were “pretty invasive” relative to the actual collision repair, he said.

It also looked like a “Word document” and was full of bullet points, he said.

In rewriting it, GM sought to determine the best set of steps for a technician which would still ensure a “safe and proper inspection” delivering a correctly repaired vehicle, according to Eck.

The automaker considered what a technician would need to have in a “decision tree,” Eck said. The new document is largely presented in what Eck called a “grid-type format” and effectively acts as a flowchart.

The chart still demands certain inspections after every repair. There’s a seven-step seatbelt inspection which is non-negotiable and must always be conducted, according to Eck.

But after that’s done, GM only calls for extensive inspections and/or replacements in “instances of vehicle collision where damage exceeds minor outer body panel cosmetic distortion.”

“It’s really not ‘our’ new definition,” Eck said of the concept. He said the “minor outer body panel cosmetic distortion” threshold had been put forth already by other OEMs. (For example, here’s a variation from Subaru.)

On minor collisions where no damage arose beyond “minor outer body panel cosmetic distortion,” the repairer would simply replace or repair the broken part following GM OEM procedures and move on. They wouldn’t have to conduct the more extensive inspections or replacements.

“In instances of vehicle collision where damage is limited to minor outer body panel cosmetic distortion: visually inspect vehicle for extent of damage, repair and replace components as necessary,” GM wrote in the new document.

More significant damage than that triggers the need for additional inspections and/or replacements.

And GM means truly “minor” outer body panel distortion. If a fascia is cracked and no other damage arose, it’s minor, Eck said. But if the repairer found damage to the bumper reinforcement beam behind that fascia upon teardown, then the damage has exceeded that minor threshold — it’s structural, Eck said.

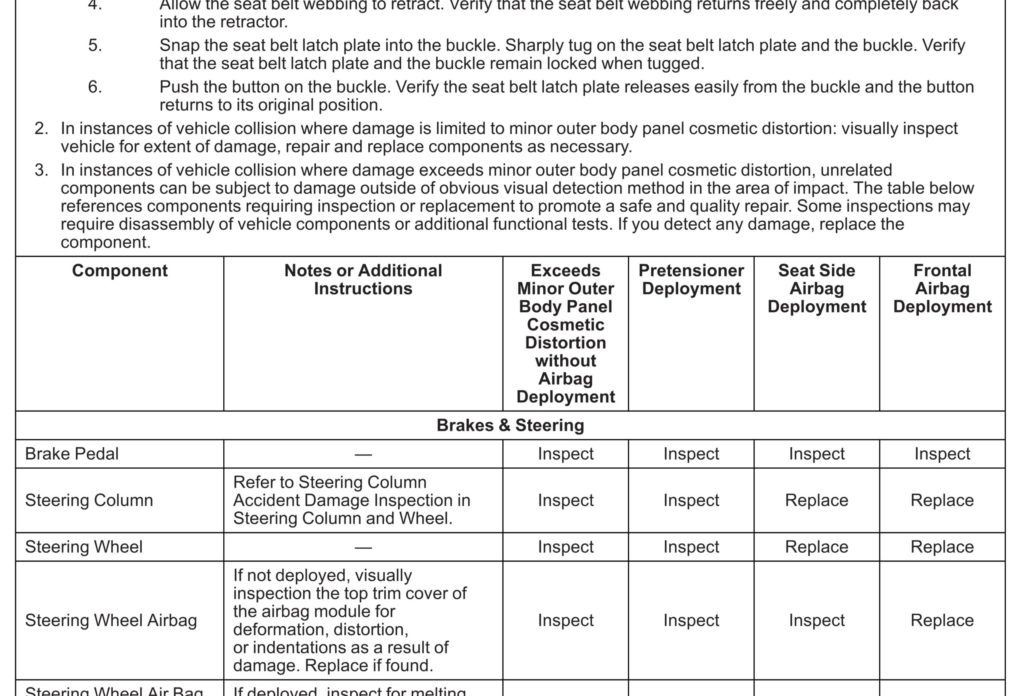

“In instances of vehicle collision where damage exceeds minor outer body panel cosmetic distortion, unrelated components can be subject to damage outside of obvious visual detection method in the area of impact,” GM wrote in the document. “The table below references components requiring inspection or replacement to promote a safe and quality repair. Some inspections may require disassembly of vehicle components or additional functional tests. If you detect any damage, replace the component.”

The document walks shops through the appropriate inspection or repair operations depending on which of four conditions exist following those more severe collisions:

- The damage “Exceeds Minor Outer Body Panel Cosmetic Distortion without Airbag Deployment.”

- A seat belt pretensioner has deployed.

- A seat side airbag has blown.

- A front airbag has blown.

Rather than simply telling a repairer to replace or inspect a component and moving on, this flowchart often features notes from GM engineers offering further clarity into the operation. Eck said GM desired the end result to be “robust,” and he said he felt this notes section would be something “a lot of technicians are going to appreciate, and hopefully, adjusters will as well.”

For example, GM’s directive to inspect the steering wheel airbag also tells you what to look for.

“If not deployed, visually inspection the top trim cover of the airbag module for deformation, distortion, or indentations as a result of damage,” GM wrote in the notes section for that part. “Replace if found.”

“It just gives you the opportunity to hear … directly from the GM engineer team” what they mean by the operation they’re requesting, Eck said of the notes section.

Scanning and calibration rules remain

The revised inspections and replacements instructions do not change GM requirements for scanning and calibration, according to Eck.

“This … doesn’t replace scanning and calibration,” Eck said.

Eck’s discussion presented an example of this distinction.

A repair or replacement involving only a bumper fascia or a side-view mirror with no other damage or airbag deployment would be an instance of minor exterior cosmetic distortion, according to Eck. The threshold for the conditional extensive vehicle inspections wouldn’t be met.

However, side-view mirrors and bumper fascias can also be relevant to advanced driver assistance systems. Eck said any work involving such a part would mean scanning and calibration of ADAS “absolutely still need to be done,” Eck said.

Development and future updates

Eck said the lengthy effort to refine the document involved “an army of people.” It drew in both GM engineering and safety personnel and required passing the GM safety review board.

“That was quite a process,” said Eck, who gave special praise to GM service engineer Jonathan Johnson for serving as the product lead.

Collision industry best practice is to always look up OEM repair procedures online fresh for each job. You don’t assume that the instructions you printed out for the repair you just finished could be reused on a similar model that just pulled in to have work done. Eck was asked Thursday how often the new “Repairs and Inspections” document would be updated.

Eck said an engineer could indeed quickly make a change to the GM OEM repair procedures website — he thought it could be updated nightly — but he didn’t see such frequency occurring with this document.

He felt GM would need the “discipline” to update it annually or twice a year. It was probably something which could be done on a “case-by-case basis,” Eck said, but he didn’t see changes occurring on a “weekly basis.”

Asked if GM had plans for a video illustrating the concepts in the document, Eck said GM hadn’t examined that option but called it a “great idea.”

Another question raised the idea that the document created new terminology for readers such as insurers to dispute.

Eck acknowledged the potential for more questions because of new wording. You try to clarify language only to think, “‘Maybe I’ve opened up a new can (of worms),'” he said.

GM knew the document wouldn’t be “perfect,” and it might raise more questions than it had intended to answer, Eck said. But the OEM was saying it was trying to bring clarity and perspective and obtain a proper inspection “‘without tearing the vehicle apart'” for a headlamp replacement.

“That was the intent,” he said.

Another question involved whether vehicle event data could serve as the guide for inspections.

Eck said GM had spent “quite a bit of time” working on how to access and use such data. Leveraging it wasn’t as simple as GM declaring, “‘Here’s the data,'” he said. He wasn’t aware of any means of pulling data that could replace the functionality of the new document for a repairer.

The next VeriFacts Guild 21 call will occur at 2 p.m. July 8.

More information:

General Motors OEM repair procedures

“Repairs and Inspections Required After a Collision”

General Motors, May 2021

Images:

The interior of the 2021 Chevrolet Silverado LTZ is shown. (Provided by Chevrolet)

General Motors announced Thursday it responded to feedback about its post-collision safety inspection and replacement requirements with revised guidance on when certain work became necessary presented in a more technician-friendly format. An excerpt is shown here. (Provided by General Motors)

Airbags are deployed on a four-door 2020 Chevrolet Blazer with four-wheel drive. (Provided by Insurance Institute for Highway Safety)