The construction industry contributes to 39% of global carbon emissions while aviation contributes to only 2% which means we need to look for alternative building materials if we are to make a big impact on the climate crisis soon. We’ve seen buildings being made using mushrooms, bricks made from recycled plastic and sand waste, organic concrete, and now are seeing another innovative solution – a floating 3D printed house!

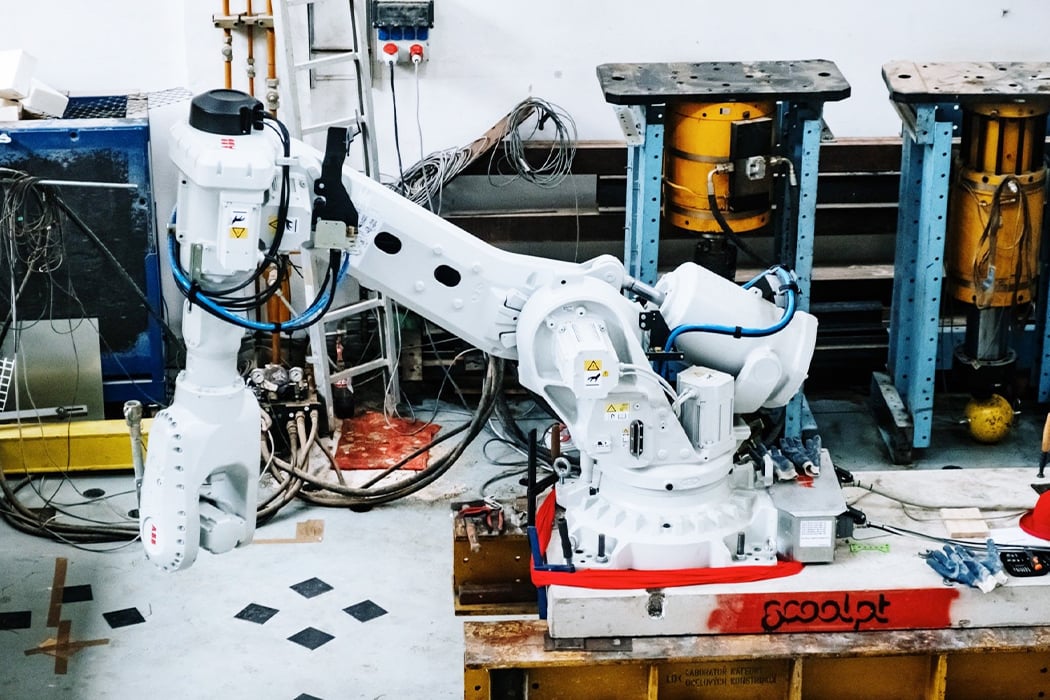

Prvok is the name of this project and it will be the first 3D printed house in the Czech Republic built by Michal Trpak, a sculptor, and Stavebni Sporitelna Ceske Sporitelny who is a notable member of the Erste building society. The house is designed to float and only takes 48 hours to build! Not only is that seven times faster than traditional houses, but it also reduces construction costs by 50%. No bricks, cement, and concrete (responsible for 8% of CO2 emissions alone!) are used which means it reduces carbon emissions by 20% – imagine how much CO2 could be reduced if this was used to build a colony. A robotic arm called Scoolpt designed by Jiri Vele, an architect and programmer, will be used in 3D printing and can print as fast as 15 cm per second.

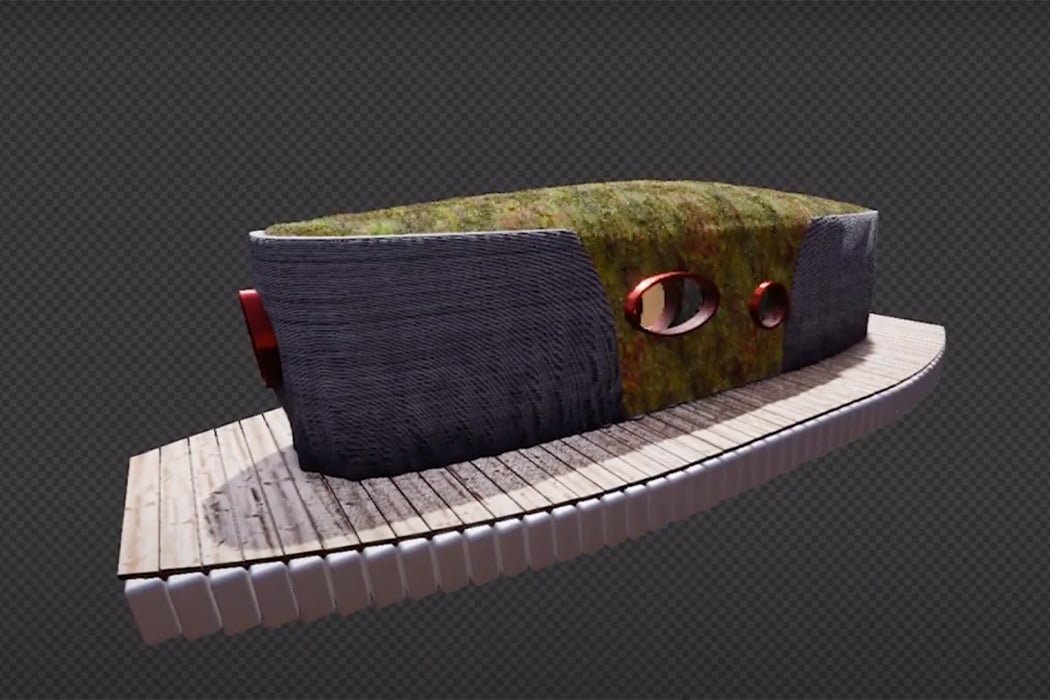

The 43 square meter home will have all the essentials – a bedroom, living room, kitchen, and bathroom. It will be anchored on a pontoon and is designed in a way that owners can live in it all year round. Prvok is partially self-sufficient and is equipped with eco-technologies that enable it to recirculate shower water, use a green roof, and host reservoirs for utility, drinking, and sewage water. Each detail and element of the house has been thoughtfully added after making sure it can last for 100 years in any environment. Prvok is an example of what the future of hybrid houses that work for you and the environment could look like.

Designers: Michal Trpak and Stavebni Sporitelna Ceske Sporitelny