Despite the growing demand and supply of renewable energy sources, we still rely on fossil fuels for much of our global energy. But deep below the ocean, there is a source of clean carbon energy waiting to be harvested, which will go a long way to reducing our dependence on oil, gas and coal – seaweed.

A recent study in Nature Geoscience estimated that seaweed floating down to the depths of the ocean naturally sequesters 173 million tons of carbon a year, about as much as New York City emits, and companies are looking for ingenious methods of harvesting this untapped energy.

It’s one of the extraordinary projects that are explored in the new book After Geoengineering: Climate Tragedy, Repair, and Restoration by Holly Jean Buck, which examines the innovative methods being employed to combat climate change.

In this extract from the book, she talks to one of the companies that are using huge kelp farms to create biofuels, which could one day be added to the growing list of renewable energy technologies that could help restore the planet.

Ocean Food and Energy Farms

Capture sunlight, turn it into fuel: it sounds like a futuristic formula. Yet one of the pioneering efforts in kelp cultivation, the Ocean Food and Energy Farm project (OFEF), began in 1972 with an infusion of US Navy funding. OFEF also gleaned funding from the United States Energy Research and Development Administration (the forerunner of the Department of Energy), the National Science Foundation, and the American Gas Association, which hoped that methane production on a significant scale could contribute to the national gas supply. (Just imagine a constellation of players like this interested in seaweed fuels today.)

“If successfully realised, this technology would enable the planet’s oceans to become a huge new source of feeds, foods, fuels, and chemicals - fixed carbon and fixed nitrogen - for the benefit of humanity,” wrote the project leader, Dr. Howard Wilcox, noting that the major question was economic feasibility. “But” he added, “the issue is more one of ‘when’ rather than ‘whether’ the concept will eventually pay off.”

Wilcox’s concept was to grow the giant kelp Macrocystis in the surface waters of the open ocean. Because most of these surface waters are a desert, nutrient wise, he proposed to pump water up from the nutrient-rich waters that lie about 300 meters below. But building the structures on which kelp would grow, as well as the mechanisms for pumping water up, presented immense engineering human efforts to cultivate this fluid terrain. How could the kelp be held together in a farm unit without being lost to tides and currents?

Read more about geoengineering:

- Could geoengineering cause a climate war?

- Seven audacious ideas to reverse global warming

- How to stop a volcano

To solve these problems, Wilcox imagined free-floating farms that would use propulsion systems to keep them circulating around the ocean’s massive eddy patterns. The scale was also a problem: to make fuel out of kelp, you need a lot of it. Dr Wilcox’s calculations indicated that the farms would have to stretch 100,000 acres or more to be a cost-competitive source of energy. Moreover, at the end of the 1970s, the gas sector was deregulated, and oil embargoes ended. And by 1982, the funders were no longer interested.

However, there has been remarkable progress in engineering in marine environments, and technology more broadly, since the 1970s. Could advances in robotics help kelp farms scale? The startup Marine BioEnergy could be seen in some sense as a descendant of OFEF, as it was founded by the son of Dr Howard Wilcox, Brian Wilcox, and his wife, Cindy.

Marine BioEnergy is investigating cultivation of long-line kelp in robotic farms—work that has attracted press interest from the likes of Fast Company, National Public Radio, and the New York Times. The new kelp farm concept is simple: the entire kelp farm gets moved down at night to receive nutrients from deeper waters, and up during the day to reach sunlight. This is a significant difference with the 1970s concept: submerging the kelp rather than building a large pumping infrastructure saves a lot of money because it means the farms can be smaller.

Drone submarines would tow these kelp farms to new waters, communicating with harvesters by satellite, which would save labour costs. The drones could also submerge the farms to avoid big storms and passing ships. It’s an ambitious but well-thought-out project, involving many collaborators and supported by ARPA-E (the US government agency tasked with promoting and funding research and development of advanced energy technologies).

The first step for the Marine BioEnergy consortium is to figure out the mechanics of kelp farming. As Cindy Wilcox told me, “Right now the biology question is the dominant question: Does a fast-growing kelp thrive when submerged to depth to absorb nutrients and surfaced during the day to absorb sunlight?”

If you're enjoying this feature, you might also enjoy a recent episode of the Science focus Podcast, where we spoke to the visionary scientist and environmental thinker, Jame Lovelock.

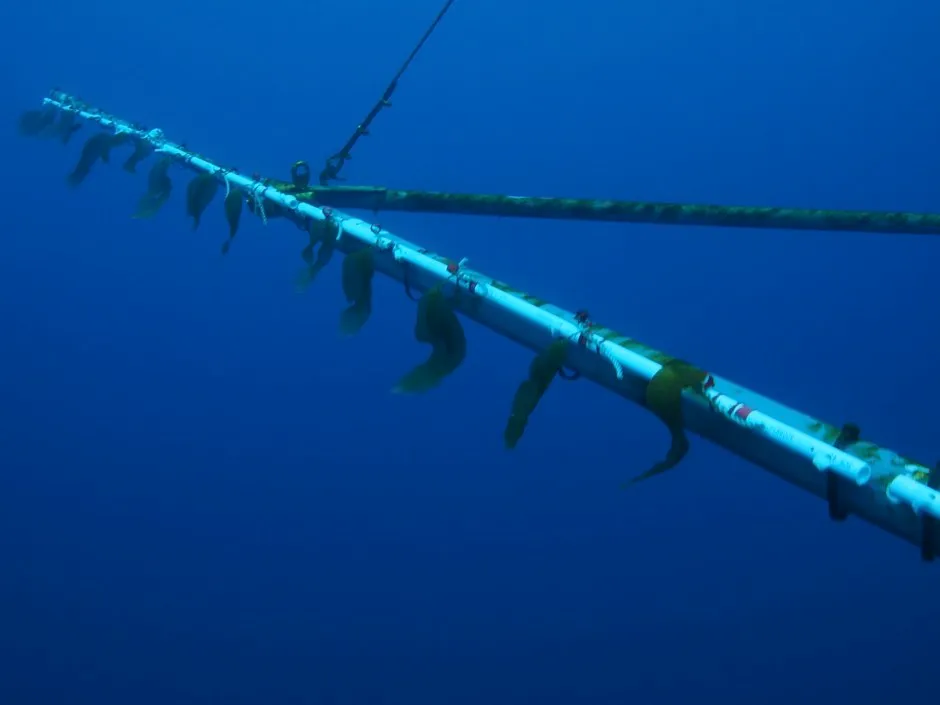

Marine BioEnergy is working with marine biologists and scientific divers at the University of Southern California to better understand this piece of the puzzle. The various species will be tested on an anchored research buoy - also known as “the kelp elevator” - near Catalina Island. The buoy has a boom that is surfaced during the day and submerged at night to find out which species thrive in this environment.

The target kelp, Macrocystis, grows a foot (30cm) a day with adequate nutrients. Moreover, some of these kelp plants have been found to grow up to three times faster than their neighbours, implying that there is much more to learn about why some plants are more productive (something other researchers are also working on).

The second step is to harvest the kelp and make a biocrude out of it. Researchers at Pacific Northwest National Labs have devised a process to convert kelp into biocrude (a hydrothermal liquefaction and catalytic hydrothermal gasification process) that takes about an hour in a reactor and doesn’t require fermentation; in theory, methane output from the process itself could be used as power source.

Then, an open question is whether it makes more sense to bring the harvested kelp back to land to process it, or instead to process it on the open ocean and have tankers come and fill up out there. Marine BioEnergy’s latest idea is to rendezvous the drones with the harvesters four times a year.

The technology for all of this exists, but it needs to be integrated for this new application, Cindy Wilcox told me. “Right now we are working to determine the most cost-effective methods to implement the subsystems and get the end-to-end process underway.”

The fuel could also complement renewables, supplying both liquid fuels and methane: as Cindy Wilcox suggests, on days without wind or Sun to power the grid, carbon-neutral methane could fuel the turbines. “We don’t expect batteries or pumped hydropower to provide adequate storage on the scale needed at a cost-competitive price. Kelp-based methane pumped through the current pipelines will meet the need and stabilise the grid,” she explains.

This is an edited extract from After Geoengineering: Climate Tragedy, Repair, and Restoration by Holly Jean Buck, which is available now (£16.99, Verso)