iPROBE helps simplify the process to identify more ecologically friendly chemicals for various industries.

August 31, 2020

As the interest in developing more sustainable solutions across various aspects of technology and manufacturing increases, researchers have been searching for new and better ways to identify materials for these solutions.

Now scientists at Northwestern University have come up with a new rapid-prototyping solution that could help solve this issue in one particular field, biomanufacturing, to reduce the time to produce sustainable biomanufacturing materials that can work like existing chemical compounds from months to weeks.

The new platform called in vitro Prototyping and Rapid Optimization of Biosynthetic Enzymes (iPROBE), provides a design-build-test framework to help engineers discover optimal biosynthetic pathways for cellular metabolic engineering. The platform could be used to identify more quickly sustainable materials for a range of industries, from clean energy to consumer products.

Researchers long have known that industrial biotechnology, which uses microbial cellular factories to leverage enzymes that can convert molecules to desirable chemical product, can help provide more sustainable and ecologically friendly materials for industry. However, to develop these cell pathways has historically been a complex and slow process that so far hasn’t been able to keep up with manufacturing needs.

iPROBE could now solve this by demonstrating “that cell-free platforms can inform and accelerate the design of industrial cellular systems,” said Michael Jewett, a professor of chemical and biological engineering at Northwestern’s McCormick School of Engineering.

“We accomplished in approximately two weeks what traditionally would have taken six to 12 months,” he said in a press statement. “Our findings will help accelerate the pace at which we can enable sustainable biomanufacturing practices.”

Speeding Up the Process

Researchers demonstrated iPROBE in three separate studies. One, which describes how it functions, was published in the journal Nature Chemical Biology, while a second and third detailing how it works with specific materials—limonene and styrene, respectively—were published in Metabolic Engineering.

To manufacture sustainable chemicals, synthetic biologists typically combine protein enzymes to achieve individual molecular transformations and covert readily available materials and chemicals—such as glucose or carbon dioxide—to a new product.

However, this process currently moves extremely slowly, as testing methods require these enzymes to get encoded in DNA, placed on a single plasmid molecule, and then inserted into a living cell, a process that gets repeated each time scientists study a different set of enzymes, Jewett explained.

“The result is that the design cycles are just too slow,” he said in a press statement. “We end up needing hundreds of combined person-years of development to bring a product to market. That’s too slow to address challenges like climate change and other rapidly growing problems we face.”

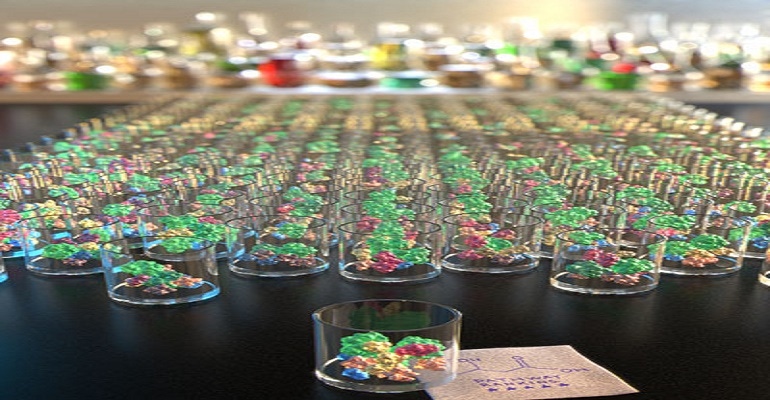

iPROBE helps to solve this problem by skipping the limitations of engineering living organisms. Instead, it uses cell-free protein synthesis to enrich biosynthetic enzymes in test tubes to carry out transformations, Jewett said

The system uses computational design algorithms developed by Lockheed Martin to study pathway enzyme ratios so it can tune individual materials in the context the desired results scientists are seeking, he said. It can screen for high-performance enzymes as well as discover enzymes with optimal functionalities.

Mix-and-Match Approach

iPROBE analyzes different enzyme combines and basically mixes and matches them to find different combinations on the way to designing biosynthetic pathways to more sustainable materials, Jewett explained, comparing it to a bartender trying to find the right ingredients for a cocktail.

“You would want to bring together all of the possible cocktail ingredients that potentially could be used,” he said in a press statement. “iPROBE allows us to mix and match enzymes in this type of cocktail-based approach to determine the best combinations to carry out the transformation and synthesis of sustainable chemicals—but instead of taking months to years to do, we can do it in days to weeks.”

Researchers tested the system by discovering optimal biosynthetic pathways for 3-hydroxybutyrate (3-HB) and butanol, two organic compounds in Clostridium autoethanogenum, a bacterium that naturally produces ethanol from metabolized carbon monoxide.

The team first identified the optimal pathways in vitro, and then shared them with collaborators at clean energy startup Lanzatech, which specializes in using Clostridium strains to produce sustainable fuel. Researchers at the company applied the pathways and said they resulted in a 20-fold increase in 3-HB production in Clostridium.

“To have this process work successfully pushes a new vision for sustainability,” Jewett said in a press statement. “This advance opens the door to one day moving from production processes reliant on fossil fuels to more sustainable, biosynthetic-based strategies.”

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like