April 16, 2018

Caffeine is a stimulant that many people rely on to jump start their day and get them on the other side of the mid-day hump. It turns out that it also does a number on polymers. Researchers at the Massachusetts Institute of Technology (MIT; Cambridge, MA) and Brigham and Women’s Hospital (Boston) are using it to catalyze the formation of polymer materials. They have devised a way to create gummy, biocompatible gels that could be used for drug delivery and other medical applications, and it all begins with a cup of deep black joe, or at least its active ingredient.

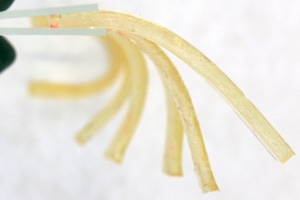

|

Image courtesy the researchers/MIT News Office. |

“Most synthetic approaches for synthesizing and cross-linking polymeric gels and other materials use catalysts or conditions that can damage sensitive substances such as biologic drugs,” explains Robert Langer, the David H. Koch Institute Professor at MIT and one of the study’s senior authors, in an article on the MIT website. “In contrast, here we used green chemistry and common food ingredients. We believe these materials could be useful in creating new medical devices and drug-delivery systems.”

In a paper published in the journal Biomaterials, the researchers explain how they loaded the gels with two antimalarial drugs. They expect the material could also be used to carry other types of drugs. Drugs carried by this kind of material could be chewable or easier to swallow, according to the researchers.

“It’s really appealing for patient populations, especially children, who have difficulty with swallowing capsules and tablets,” says Giovanni Traverso, a research affiliate at MIT’s Koch Institute for Integrative Cancer Research and a gastroenterologist and biomedical engineer at Brigham and Women’s Hospital. He is also a senior author of the paper.

Making polymer gels usually requires metal catalysts, which could be hazardous if any of the catalyst remains in the material after the gel is formed. The MIT team wanted to come up with a new way to make gels using catalysts and starting materials that are based on food products and other materials that are safe to ingest.

“Our goal was to try to simplify the method of manufacturing and impart an improved safety profile from the beginning by using potentially safer catalysts,” Traverso told Anne Trafton at the MIT News Office.

Although caffeine has not been used for chemical synthesis before, it drew the researchers’ attention because it is plant-derived and can act as a weak base, meaning that it gently removes protons from other molecules. It also has a similar structure to some other organic weak bases that have been used to catalyze the type of chemical reaction needed to form these gels—the formation of ester bonds to create a polyester.

“Polyesters allow for the intentional design of ingestible materials made from bio-derived resources,” said Angela DiCiccio, a former MIT postdoc who is now at Verily Life Sciences, the life sciences division of Google X, and is the lead author of the paper. “However, there didn’t exist any catalysts that were mild enough to enchain these molecules without causing unwanted reactions or requiring super high heat. Our new platform provides an elegant solution to this problem using inexpensive materials and broadly accessible chemistries,” DiCiccio told Trafton.

The researchers decided to use caffeine to induce citric acid to form a polymer network along with polyethylene glycol (PEG). When mixed with citric acid and PEG, and slightly heated, caffeine opens up an oxygen-containing ring in the PEG, allowing it to react with citric acid to form chains that consist of alternating molecules of PEG and citric acid. If drug molecules are present in the mixture, they also become incorporated into the chains.

The researchers can vary the chemical and mechanical properties of the gel by altering its composition. They created gels that contain either PEG or polypropylene glycol, as well as some that combine the two polymers in different ratios. This allows them to control properties such as the material’s strength, surface structure, and the drug-release rate.

“Depending on what the application may be, or what drugs are being incorporated, you could mix and match to find an optimal mixture,” Traverso said.

The gels can also be imprinted with patterns such as the microscale architecture found on the surface of lotus leaves, which allows them to repel water. Altering the surface traits of the material could help researchers control the rate at which the gels move through the digestive tract.

The resulting gels contain a small amount of caffeine, roughly the same as that found in a cup of tea. In preliminary safety tests, the researchers found no harmful effects in four types of human cells, or in rats.

About the Author(s)

You May Also Like