Young fans of the series by JK Rowling, the first entry of which was published in 1997, were awed by the oddly-coloured cloak’s properties – when worn, it made every part of the body covered by the cloak entirely invisible.

Little did they know that within a few years, in 2006, a real invisibility cloak would be made. Instead of magic, this cloak was formed of a nano-engineered material that bent light waves around it. The man behind the invention was physicist Sir John Pendry. His ideas heralded the beginning of a new class of materials that could manipulate the properties of light to do things previously thought impossible – metamaterials.

“A metamaterial is a material that owes its properties more to structure than chemical composition,” says Pendry, “and that structure has to be on a scale that is less than the wavelength of any waves going through it.” Metamaterials use their unique structures to do things not found in nature, like creating prisms that refract light the ‘wrong’ way, or lenses that can focus to smaller scales than previously thought possible. But, despite their huge potential and the vast amount of research into them, there has been very little in the way of marketable application. Until now.

“Until recently there was no way of manufacturing what you could dream up because it was simply too expensive,” says George Palikaras, founder and CEO of Metamaterial Technologies Inc (MTI), a Canada-based metamaterials company. “Because of the availability now of manufacturing tools and the right cost metamaterials are starting to take off.”

MTI uses a combination of techniques to nano-structure materials that can manipulate electro-magnetic fields for real-world applications. One of these is metaAIR, an optical filter that can protect pilots from the growing problem of laser strikes. “Over the last four years there’s been about 40,000 laser strikes reported in the US, UK and Canada,” says Palikaras, “and recently a pilot suffered burnt retinas due to a laser strike.”

The metaAIR film can be applied to pilots' glasses to protect from harmful lasers

Developed alongside Airbus, metaAIR comes in the form of a transparent film that can be applied to cockpit glass or a pilot’s glasses, blocking 99.999% of harmful laser radiation while maintaining high transparency and colour balance. This is achieved through holographic exposure where lasers are used to create hundreds of nanometre-scale layers, each of which reflects a different frequency of light.

Transparent heaters

Another application, the so-called NanoWeb, uses optical lithography to essentially print patterns of conductive material onto transparent films. With this technique MTI has created transparent heaters that can be applied to glass, enabling it to automatically de-mist and de-fog itself. The technology has obvious applications in transport, especially in cold and humid climates, but is especially crucial to the growing electric vehicle (EV) market.

“Anything the EV market works with has to be ultra-lightweight,” says Palikaras, “and they have very big fans pushing air to the front window. If they can replace these with NanoWeb that means they can save 20-30kg. That translates into more range and more value.”

Foldable phones

And there’s more – transparent 5G antennas, increased-efficiency solar cells and augmented-reality glasses are just some of the other technologies MTI is working on. It even has a replacement for indium tin oxide (ITO), the transparent metal that forms the conductive screens of our smart devices – one that will become increasingly important as the market moves towards bendy and foldable phones.

“You can’t bend ITO higher than a 2mm radius,” says Palikaras, “whereas our materials are so robust, you can take our film and crush it in your hands or do origami with it.”

MTI is working with the UK government and NHS to develop a non-invasive way of measuring blood glucose levels of diabetes sufferers by sending a signal between two sensors placed on either side of the soft tissue at the base of thumb and forefinger. It is also working on a metamaterial resonator which can be used to dramatically increase the efficiency of MRI scanners. “We improved the signal by 50 times,” says Palikaras, “so a 60-minute scan becomes two minutes.”

Other companies are using metamaterials to create revolutionary new products. One example is Kymeta which makes satellite communication receivers that can run off low power, operate anywhere, and cost a fraction of an old-fashioned satellite dish. Kymeta has partnered with Toyota to incorporate its flat-panel antennas into car roofs, enabling them to receive data at broadband speeds.

Another company doing interesting things is Oxford University spin-out Metaboards, which uses metamaterial principles for wireless charging and data transfer applications. Metaboards’ charging pads provide competition to current wireless charging systems such as Qi, with several advantages. They can charge multiple devices without loss of power to each separate device. And devices don’t have to be aligned in a particular direction for charging to occur. Perhaps most importantly, the technology doesn’t fill our work and living spaces with potentially harmful electromagnetic fields.

The Metaboards wireless pad can charge multiple devices at once without loss of power to any of them

“The electromagnetic field is only present where the device is present,” says Nedko Ivanov, Metaboards’ CEO. “So it doesn’t have to be present across the whole surface.” This is achieved not through complicated nano-engineering but with simple PCBs. It is the way these electrical components are arranged and interact that makes the whole thing a metamaterial.

“The charging pad is formed of resonators made from standard PCB circuits,” explains Ivanov. “When you put all these resonators next to each other, they start to interfere and create all these strange kinds of resonance. The way the device can control and manage these behaviours rather than the uniqueness of the materials themselves is what makes them metamaterials.”

Charging no chore

At the moment the charging device is a rather familiar-looking pad but Metaboards is researching ways of integrating its wireless charging into all kinds of everyday materials so that mobile charging can become a chore we can effectively forget about. “All the applications are about merging wireless charging into our environment,” says Irina Khromova, Metaboards’ head of science and technology. “So the table becomes a charger, or the kitchen worksurface or the bedside table. The integration of electronics and furniture will be the future, where you can just put your phone down on a piece of furniture and charge it.”

Metaboards also wants to turn furniture into a data transfer medium. This would be more secure than everyday wireless where data can be intercepted if someone knows the password. Imagine a conference where two people want to share data in privacy. They simply place their phones on the conference table which transmits the information confidentially from device to device.

The team is even researching ways of re-harvesting all the wasted energy floating around us, emitted from our millions of electronic devices. “Metamaterials are all about tailoring fields so they behave how we want them to behave,” says Khromova, “so that’s one of the first things that comes to mind – can we use this to recycle some of the residual energy floating around?”

Earthquake protection

If it seems surprising that PCBs can be metamaterials, how about holes in the ground? This is exactly what a group of researchers led by a team from Imperial College London is using to protect structures from earthquakes. The group showed that holes drilled down to the bedrock and filled with concrete could form a zero-frequency stop band, essentially a seismic shield that partially reflects and absorbs seismic waves. And yes, it is considered a metamaterial.

“A metamaterial is just a smart medium, that’s all it is,” says Sébastien Guenneau, from Aix-Marseille University in France, who works on the project. “There is nothing new in reality. It’s just rediscovering science from 100 years ago but with new applications.”

Seismic shields could protect structures from earthquake damage

The research arose from earlier experiments which found that unfilled holes 5m deep and 30cm in diameter could act as an earthquake shield when positioned at regular intervals around a building in sedimentary soil – an idea which itself was inspired by an optical phenomenon. “You can drill nanometre holes in glass,” says Guenneau, “and you can make it opaque – it can be a mirror. Instead of drilling nanometre holes in glass we drill centimetre or metre holes in soil – same concept.”

The team has even shown that a ring of trees surrounding a building can have the same shielding effect, effectively turning a forest into a metamaterial, a phenomenon which French project Meta-Foret is studying. Guenneau is using the same principle to protect sections of the French coast. His team is working with the French government to drive wooden pillars into the sea along parts of the coast vulnerable to wave erosion. The pillars absorb and reflect ocean waves in exactly the same way as the concrete pillars do with seismic waves. And similar techniques are being researched to lessen the devastating effects of tsunamis in Indonesia.

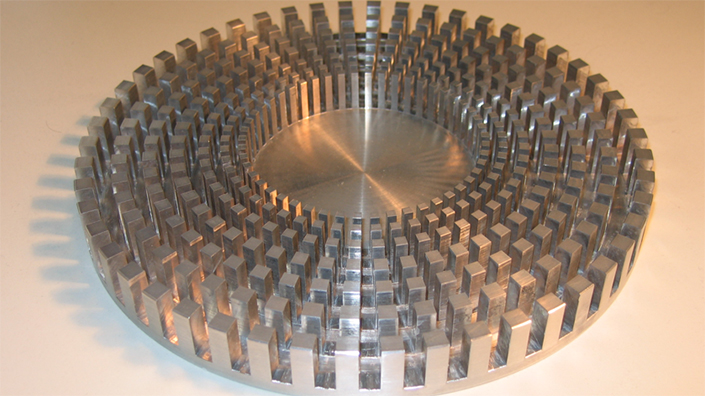

In the meantime, Pendry, the forefather of metamaterials, has remained busy at the cutting edge of research, especially where it intersects with the science of plasmonics. Pendry’s team at Imperial College London is looking into ways of using surface plasmons – quantised particles generated by the oscillation of free electrons in metals – to interact with electromagnetic waves. These plasmons do not usually interact with outside fields, but by altering the structure of a metal’s surface by, for example, grinding it into small nano-spheres the plasmons are freed to interact, causing several interesting effects.

One application is a ‘superlens’ that can bend normal light beyond the refraction limit. “We can concentrate light in these structures which have traps in them,” says Pendry, “and these traps are a realisation of the perfect lens. The plasmons are capturing the light and funnelling it down. So you can focus light now to better than a nanometre and that’s 1,000 times better than you could with a normal lens.”

Another application is in cancer treatment. Research from a team at the University of Texas has shown that gold nanoparticles can be used to seek out and attach themselves to cancer cells. A laser is then shone on the nanoparticles which, using the same plasmonic effect as in the superlens, causes them to vibrate and pulse with extreme temperatures, killing the cancer cells.

Solving new problems

Metamaterials, it seems, are percolating into every field of research from the very big to the very small, from high tech to low tech, from entertainment to life-saving medicine. Could they become the everyday materials of the next generation? Palikaras thinks so. “I feel that metamaterials are going to solve problems in the next five to 10 years that no one knew existed,” he says. Khromova agrees, pointing out the number of papers published on the subject each year which, she says, is growing exponentially.

Pendry likens it to the laser which, when it was invented in the 1960s, had very few applications. “Who would have thought then that lasers would be welding cars together, doing eye surgery or that the internet would be powered by them,” he says. “I believe that the same will be true of metamaterials as people become aware of the potential and look at new problems and do new things. If I could tell you what will happen, it wouldn’t be a surprise. But you will be surprised, I’m sure of that.”

The real invisibility cloak

The invisibility cloak built by Sir John Pendry and a team from Duke University in North Carolina wasn’t much like Harry Potter’s cloak at all.

The object was less than 13cm across and was only invisible to microwaves, not visible light. Still, the tiny piece of metamaterial had the ‘magical’ effect of bending microwave radiation around itself, much like the way water flows around stones in a stream.

The material was fashioned from nano-scale, two-dimensional concentric rings that interacted with microwaves to bend them around the object, so effectively cloaking anything placed immediately behind it in the zone from which the light rays were deflected.

Want the best engineering stories delivered straight to your inbox? The Professional Engineering newsletter gives you vital updates on the most cutting-edge engineering and exciting new job opportunities. To sign up, click here.

Content published by Professional Engineering does not necessarily represent the views of the Institution of Mechanical Engineers.