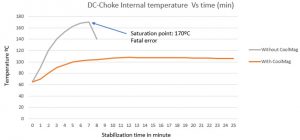

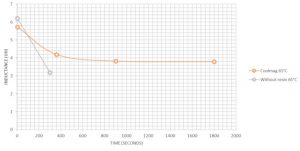

“CoolMag is a thermally conductive compound able to fill any space between winding and core, and between core and heat-sink,” said the firm. “It is enough to reduce temperature by more than 40ºC.” (graph right)

“CoolMag is a thermally conductive compound able to fill any space between winding and core, and between core and heat-sink,” said the firm. “It is enough to reduce temperature by more than 40ºC.” (graph right)

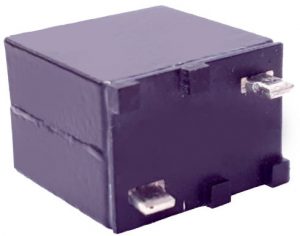

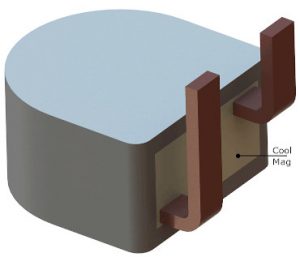

To find a suitable potting compound, 30 thermally-conductive materials of various types from various manufacturers were assessed within a 3.3kW automotive on-board charger in instrumented FeSi6 chokes and transformers. (research choke below left)

“The first finding was that the transformers that are not filled or that have air present reached up to 140-150°C while the average filled transformer and choke showed temperatures below 80°C,” according to Premo. “So, an efficient cooling system in a 3.3kW device can save up to 60°C of temperature increase while reducing unwanted effects such as Curie temperature, dilatation, magnetostriction and electrical insulation deterioration versus time.”

“The first finding was that the transformers that are not filled or that have air present reached up to 140-150°C while the average filled transformer and choke showed temperatures below 80°C,” according to Premo. “So, an efficient cooling system in a 3.3kW device can save up to 60°C of temperature increase while reducing unwanted effects such as Curie temperature, dilatation, magnetostriction and electrical insulation deterioration versus time.”

Other findings were that:

- phase-change materials move even more heat, resulting in temperatures 85°C cooler than just air

- measured thermal conductivity was no guide to how any particular material performed, as final temperature was also affected by thermal diffusivity, specific heat, electrical eddy currents and minimum achievable wall thicknesses

Finally chosen to become CoolMag, was a material from supplier Kadion. “The company made a customised solution for Premo with superior performance in almost all categories to the better known suppliers,” said Premo, “It provided better performances at lower cost than the market standards.”

Finally chosen to become CoolMag, was a material from supplier Kadion. “The company made a customised solution for Premo with superior performance in almost all categories to the better known suppliers,” said Premo, “It provided better performances at lower cost than the market standards.”

Inductance vs time as a choke heats

Inductance vs time as a choke heats

And it has other characteristics: “Coolmag is a thermal resin for heat management and fire prevention,” Premo spokesman Rocio Arrupe told Electronics Weekly. “Applications go beyond transformers and electronics, as it can efficiently cool down lithium batteries and prevent flames.”

Premo develops, manufactures and sells products including: RFID antennas, AR+VR motion tracking sensors, power transformers, inductors, chokes, current sensors and EMC filters. It has >1,200 employees over five design centers and three production locations (Morocco, China & Vietnam).

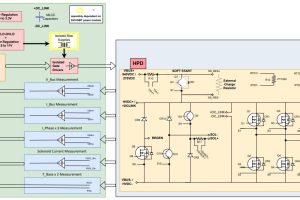

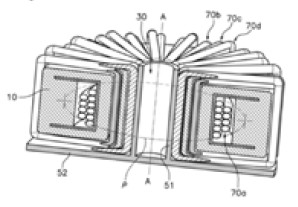

In 2016 the firm found a way to use the same magnetic material to implement two separate inductive components, by keeping the two sets of magnetic fields orthogonal at all times – technology that was subsequently branded 3DPower. (diagram right)

In 2016 the firm found a way to use the same magnetic material to implement two separate inductive components, by keeping the two sets of magnetic fields orthogonal at all times – technology that was subsequently branded 3DPower. (diagram right)

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News