It is a vacuum deposition process that works with copper and silver, and exploits the different ‘condensation coefficient’ (‘C’) of two materials.

“Thermal evaporation is already widely used on a large scale to make the thin metal film on the inside of crisp packets, and organofluorine compounds are already common place as the basis of non-stick cooking pans,” said the university.

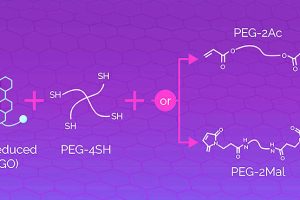

First, the substrate – glass, plastic or silicon – is coated with an even layer of a high-C material – something that the metals like to condense onto when evaporated nearby. Thin films of both vacuum-deposited molybdenum oxide (10nm thick) and wet-processed polyethylenimine have both been shown to work for this.

Where metal must not form a layer, a low-C material – the organofluorine compound known as ‘FTS’ – is deposited.

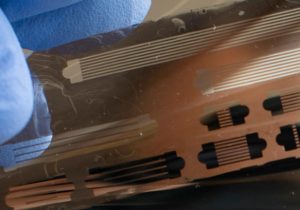

For the research, the FTS pattern was pressed onto the substrate using ‘micro-imprint lithography’ – essentially a tiny version of children’s potato printings, and a process which scales to mass production.

For the research, the FTS pattern was pressed onto the substrate using ‘micro-imprint lithography’ – essentially a tiny version of children’s potato printings, and a process which scales to mass production.

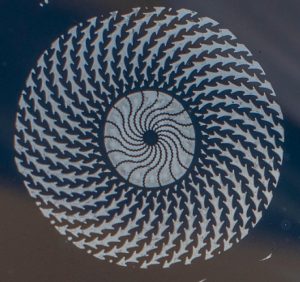

One of the demonstration patterns was an array of 2.5μm circles, at a density of about six million/cm2. Another involved depositing grids of ~1μm lines.

The FTS layer only needs to be 10nm thick to repel all of the silver or copper. And the high-C under-layer between the patterned areas ensures good metal coverage where it is needed, and a crisp transition to no metal where it is not needed.

Applications are foreseen making electrodes for flexible solar panels, in sensors, and on low-emissivity glass.

“This unconventional approach leaves the metal surface uncontaminated, which [team member Dr Ross] Hatton believes will be particularly important for the next generation sensors, which often require uncontaminated patterned films of these metals as platforms onto which sensing molecules can be attached,” according to the university.

“This unconventional approach leaves the metal surface uncontaminated, which [team member Dr Ross] Hatton believes will be particularly important for the next generation sensors, which often require uncontaminated patterned films of these metals as platforms onto which sensing molecules can be attached,” according to the university.

The work is described in ‘Selective deposition of silver and copper films by condensation coefficient modulation‘, a paper published in Materials Horizons. “We have fabricated semi-transparent organic solar cells in which the top silver electrode is patterned with a dense array of 2μm diameter apertures, which cannot be achieved by any other scalable means directly on an organic electronic device,” according to the paper.

This project received £1.15 M funding from the UK Engineering and Physical Sciences Research Council.

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News