ANDREY ANDREEV

Two-photon microscopy, a fluorescence-imaging technique used by many researchers in the life sciences, has over time become a mature application. The single most expensive piece of equipment in two-photon microscopy setups is the femtosecond laser—a technology that most biologists are unfamiliar with. The most common type used is the titanium sapphire (Ti:sapphire) tunable laser, which can cost up to $200,000; however, cheaper and smaller fixed-wavelength fiber lasers have become available that can deliver similar results.

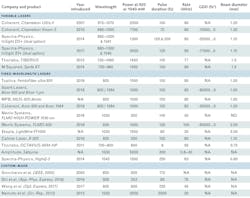

A head-to-head comparison between Ti:sapphire and fiber femtosecond lasers for imaging shows that their performance is very similar.1 Currently, more than dozen companies offer laser sources for two-photon microscopy; with the large number of laser parameters added in, making a decision can be difficult. This article describes which characteristics of these two types of lasers are critical for imaging experiments and aims to assist researchers in making informed decisions about purchasing.

Femtosecond lasers and biological discovery

Several types of microscopy experiments rely on femtosecond lasers. The focus here will be on deep-brain imaging in mice and whole-brain imaging in zebrafish with two-photon fluorescence and optogenetics. The absorption spectrum range of fluorescent proteins and light-gated ion channels is usually 900–1100 nm (the near-infrared range). Long-wavelength light allows for deeper penetration and lower scattering, and use of invisible light allows for light-sensitive experiments in transparent animals. Two-photon fluorescence requires high power—on the order of 100 mW, compared to microwatts for single-photon imaging. The absorption efficiency also depends on the light energy, which makes it more useful to use short-pulse sources such as femtosecond lasers.

Researchers interested in these applications have traditionally relied on tunable Ti:sapphire lasers (developed around 1986) that output light of desired wavelengths within the range of 700 to 1000 nm. Numerous companies currently offer these systems. The ability to select wavelength allows for multicolor imaging using a flexible set of fluorophores, and spectroscopy applications such as design of new fluorophores.

Much experience has been accumulated with Ti:sapphire systems. The main drawbacks of these systems include significant cost above $120,000 and physical size and weight that prevent the flexibility to move the source between imaging setups. It might be hard for a lab or imaging core to provision such investment, as average lab equipment budgets are around $100,000 per year (as reported by Lab Manager in 2011).

Single-wavelength femtosecond lasers are a newer technology that emerged around 2004. These sources are smaller and cheaper, starting at around $40,000, while providing light with similar characteristics to Ti:sapphire laser light, but without the ability to tune the output wavelength. Smaller and more power-efficient operation allows the use of air-chilling instead of water-based chilling (see figure). However, there has been less experience with these systems, especially when comes to operation stability and service.What is being offered right now

There are several parameters that define lasers for imaging (see table). First and foremost is the wavelength. Commonly used fluorescent proteins such as GFP and GCaMP are excited by 920–940 nm light, while red-shifted proteins are excited by 1040–1100 nm light:

Protein Two-photon excitation (nm)

eGFP and GCaMP6 850–950

tdTomato, RFP, and RCaMP 1050–1100

ChR2 920

ReaChR 970–1020

The amount of power that is required for imaging and optogenetics should be considered carefully. Laser manufacturers are working hard to increase laser power, but in realistic imaging experiments, such high-power levels might not be necessary. Point-scanning applications use 10–100 mW of power at 920 nm, whereas light-sheet microscopy might require up to 500 mW. In these cases, having more than 1–2 W of laser power is not necessary even after accounting for typical 50% losses. One application of a higher-power laser is splitting a laser source between two or three microscopes. Finally, tunable lasers have a nonconstant power output over their wavelength range. For example, a laser emitting 2 W at 920 nm will output only 1 W at 1040 nm.

Another important parameter is laser pulse duration, as shorter pulses are more efficient at producing a fluorescent signal.2 Usually, femtosecond lasers for imaging produce 80–200 fs laser pulses. A third important number is pulse repetition rate. A standard repetition rate is 80 MHz; lower repetition rates, however, were shown to produce more-efficient fluorescence excitation at the same average power.3 Taken together, a lower rep rate and shorter pulses lead to lower photodamage, as shown in experiments with zebrafish.4

One important consideration in fast-scanning imaging methods, where just a few pulses might be used to generate a single image pixel (such as imaging with resonant scanners), is that the user will be looking for the highest pulse energy. Average power and pulse energy are linked, as follows:

Average power = pulse energy × repetition rate

The challenge in picking the right laser source for an experiment is that, for a tunable source, these parameters are interconnected. Deeper penetration can be achieved with longer wavelengths. However, power and pulse duration are a function of the selected wavelength, so optimizing all quantitative parameters might not be possible. Fixed-wavelength lasers come with factory-tested specifications, and their parameters are not adjustable.

Extra options

Laser systems often come with several features apart from the light source itself.

Some companies integrate the laser with a power-regulation system, which is an essential part of a two-photon microscopy setup, as it aids in applying the right amount of light at the right moment. However, a prospective user should consider the efficiency of such a system, as some power-regulation systems can waste up to 25% of laser power. Some custom systems—the most popular ones utilize a Pockels cell—will waste below 2–5% at around a $10,000–15,000 cost, but also require extra electronics and control schemes.

Another useful option is a built-in precompensation. Due to dispersion, a light pulse “stretches” in time while traveling through optical elements. An initial pulse that is 60 fs can be stretched to 300 fs at the sample after passing through a microscope’s optics,5 which can decrease the two-photon fluorescence signal by up to 50%. Precompensation counteracts these dispersion effects. Some lasers have built-in precompensation, which can be adjusted via computer control to account for numerous dispersive elements, such as high-quality 20X 1.0 NA objectives and mirrors. A competent engineer is needed to build a custom precompensation optical system (one solution using pair of chirped mirrors can cost around $3000).

One might think it would be beneficial to try and save costs by building precompensation or power adjustment features oneself. However, companies quote these items not only based on parts, but including labor, integration time, user interface, and robustness.

One option only provided with Ti:sapphire lasers is a dual output, where the laser produces synchronized pulses of tunable 700–1000 nm laser light and 1040 nm fixed-wavelength light from an independent output. This feature allows for truly simultaneous imaging of GFP and RFP without changing the tunable range output. To achieve the same result with fixed-wavelength lasers, one will need two lasers. In dual-output options, a fixed wavelength output usually has no precompensation, or only a factory-set precompensation value.

How to navigate the purchasing process

Interactions with sales representatives can be intimidating. The potential buyer should ask for technical information, such as laser spectrum and pulse shape (so-called FROG measurements), transmission parameters of any additional options that are being purchased, details of the cooling scheme, power and ambient temperature requirements, and whether an uninterruptable power supply needs to be installed. It is a good idea for the buyer to ask the company to enable contact with other recent buyers for a first-hand experience. Finally, inquire about the system service costs and process. Usually, companies can fix issues remotely, but one important capability that we’ve seen is quick shipment of a replacement unit in case of significant problems.

To conclude, if the researcher has a very well-defined application, such as one based on preselected fluorophores and optogenetic molecules, a fixed-wavelength laser might be a good investment. However, if one aims to be using multiple fluorophores that require different excitation wavelengths, or to be optimizing imaging parameters for new or not yet well-studied molecules, tunable lasers based on Ti:sapphire technology are an appropriate solution.

REFERENCES

1. J. M. Bueno, J. Ávila, and P. Artal, Appl. Opt., 58, 3830–3835 (2019); https://doi.org/10.1364/ao.58.003830.

2. C. Xu and W. W. Webb, J. Opt. Soc. Am. B, 13, 481–491 (1996); https://doi.org/10.1364/josab.13.000481.

3. G. Donnert, C. Eggeling, and S. W. Hell, Nat. Methods, 4, 81–86 (2007); https://doi.org/10.1038/nmeth986.

4. V. Maioli et al., bioRxiv (Jun. 3, 2020); https://www.biorxiv.org/content/10.1101/2020.06.02.130377v1.

5. J. B. Guild, C. Xu, and W. W. Webb, Appl. Opt., 36, 397–401 (1997); https://doi.org/10.1364/ao.36.000397.

Andrey Andreev is a postdoctoral scholar in the David Prober lab at the California Institute of Technology; e-mail: [email protected]; proberlab.caltech.edu.