Sculpteo Study Shows that Additive Manufacturing is Making its Mark on Industry

For the 7th year in a row, printing service Sculpteo has released its study, The State of 3D Printing, which highlights additive manufacturing users around the world. This year’s report is a little different since it also looked at the impact of the health crisis on respondents’ 3D printing activities. And it must be said that the results were globally positive: 30% of respondents claim to have increased their 3D printing operations in response to COVID-19 while 23% invested more than 100k in the sector last year. It is also important to note that the participants maintained their confidence in the technology, with more than 61% ready to invest more in 2021. The study therefore shows signs of the health of the additive manufacturing industry, confirming what was announced last year.

The 7th edition of The State of 3D Printing includes responses from 1,900 industry professionals in 86 different countries. Clément Moreau, CEO and co-founder of Sculpteo, highlights the fact that this is the first time the study has been so international. This year, what was notable was the signs of the maturing of the 3D printing sector, with more participants having chosen the technology internally and structured their activities around it. 18% of respondents created a department dedicated to additive manufacturing and 43% have been using it for more than 5 years. As you know, the technology was primarily used for rapid prototyping, but the trend has been reversed in recent years. The figures speak for themselves, with 53% of respondents using 3D printing for small series and 25% for large series.

Additive manufacturing is used in the production of small and large series (photo credits: BMW)

If we go further in terms of applications, the study shows that more companies are 3D printing finished parts, especially mechanical parts (52%) and consumer goods (27%). Tooling and the creation of spare parts are also showing significant use. This not only shows that AM can be considered a reliable, manufacturing technology but also highlights the trend of component reparability. For the fight against programmed obsolescence, 3D printing offers a very interesting alternative.

Benefits, challenges and barriers to overcome

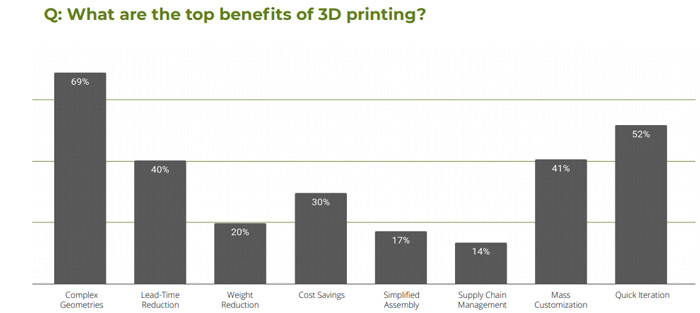

The State of 3D Printing is also an opportunity to review the main benefits of additive manufacturing. Not too surprisingly, the ability to create complex geometries and to iterate quickly remain the top two benefits (69% and 52% respectively). What has changed this year is the responses on mass customization: for 41% of respondents, 3D printing makes it easier and faster to design custom products, up from 32% in 2020. This can be explained in part by the current pandemic: 3D technologies have made it possible to manufacture personal protective equipment, personalized medical devices, etc. The medical sector has benefited greatly from additive manufacturing, which is able to offer tools adapted to each patient.

The main benefits of 3D printing (photo credits: Sculpteo)

The limitations of additive manufacturing remain more or less the same as last year, i.e. the difficulty in controlling the quality of a 3D printed part and the post-processing that is often too time consuming. Professional users stress the importance of repeatability in their manufacturing processes for example, how to guarantee the same part from one print to another? Moreover, for 59% of them, the lack of reliability of 3D printing technologies prevents optimal market growth. This is a significant barrier to entry along with added high entry costs and a lack of innovative materials. François Minec, Managing Director of BASF Forward AM, adds: “Batch-to-batch consistency and reliability of the technology, total cost of ownership, and materials enabling new applications are the keys to further driving the industrialization of Additive Manufacturing. But the whole industry also needs to raise awareness of the potentials of Design for Additive Manufacturing (DfAM).”

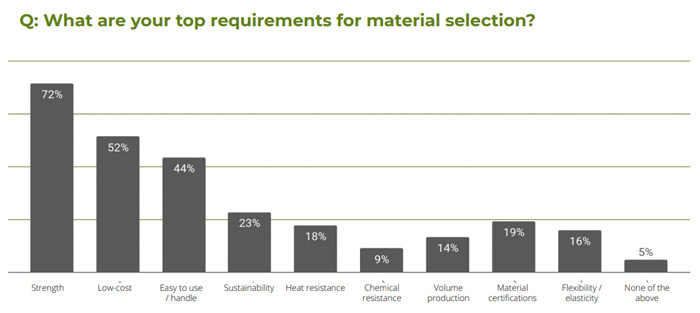

Finally, the question of materials was addressed several times. For 72% of the participants, strength is the most important characteristic they are looking for, which is not so surprising after all, since more companies are 3D printing finished parts for demanding industrial applications. Just look at the growth of high-performance materials in recent years. Price and ease of use are two other important criteria to consider when it comes to materials.

Companies are looking for resistant materials (photo credits: Sculpteo)

The impact of COVID-19 on the 3D printing market

In the end, the health crisis didn’t hurt the additive manufacturing industry so much as it did thrust it into the spotlight by demonstrating its flexibility and ability to repair broken supply chains. According to the Sculpteo study, 37% of companies surveyed had new business opportunities and higher demand for 3D printing during this period. Of course, the market could have grown even more without this pandemic. But it is showing promise for the next few years.

Ramon Pastor, VP & GM 3D Printing, HP, concludes, “COVID-19 and geopolitical and economic uncertainty have accelerated interest in adopting 3D printing to build resilient supply chains and enable local, on-demand manufacturing. As COVID-19 disrupted global supply chains and limited the ability to efficiently deliver critical materials, 3D printing emerged as a key technology to fulfill some of the most in-demand supplies. Although many companies understand the importance of digital transformation, the pandemic has led to business disruption including capital expenditure limitations, resulting in slower 3D printing growth over the past year.”

You can find the full study HERE. What do you think of the maturing of AM? Let us know in a comment below or on our Linkedin, Facebook and Twitter pages! Sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.