As more vehicles are designed to run on electricity, and especially as batteries are required to provide longer ranges, the weight of the batteries becomes more of an issue. In some cases, the battery pack could contribute 20-25 percent of the total mass of the electric vehicle (EV). The need for massless energy storage is growing.

Researchers at Chalmers University of Technology in Sweden saw this challenge as an opportunity to turn some of the car’s structural components into batteries themselves, effectively eliminating much of the battery weight as it becomes part of the vehicle itself.

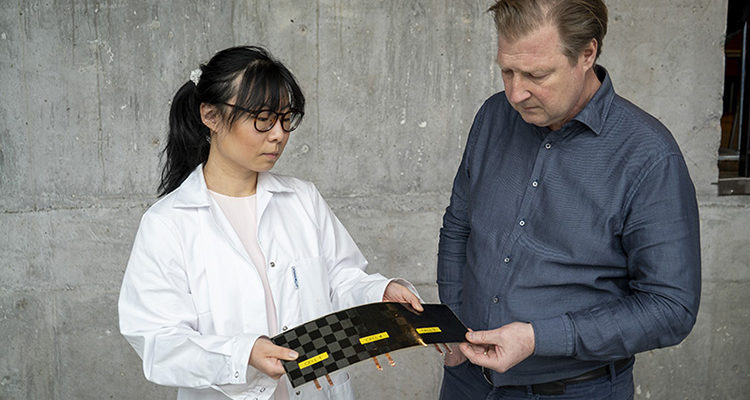

The structural battery, designed by Professor Leif Asp’s team at Chalmers University, combines carbon fiber as a negative electrode, and a lithium iron phosphate-coated aluminum foil as the positive electrode, separated by a glass fiber separator in a structural battery electrolyte matrix material. The carbon fiber anode and the electrolyte support structural loads and move ions, while the cathode conducts electrons and hosts the lithium ions. The carbon fiber stores energy and, since it conducts electrons, eliminates the need for heavier cooper and silver conductors. The glass fiber weave used, at 25.5 GPa, achieved exception stiffness to help support the structural loads.