3D printed fibers could be used in the fight against COVID-19 to monitor patients or detect weaknesses in face masks.

October 27, 2020

Researchers have developed tiny conducting fibers thinner than a human hair that can be used to develop wearable technology with acute sensing capabilities that can be used for health monitoring, biosensing, and the Internet of things.

A team at the University of Cambridge developed the electronic fibers, which themselves having sensing capabilities that perform beyond what is currently possible with film-based devices used today.

Using a novel fiber-printing technique, the team—led by Yan Yan Shery Huang from Cambridge’s Department of Engineering—can fabricate non-contact, wearable, and portable respiratory sensors that are highly sensitive yet can be made for a relatively low cost.

The composite fibers are comprised of silver and/or semiconducting polymers in a printing technique that creates a core-shell fiber structure. A high-purity conducting fiber core is wrapped by a thin protective polymer sheath in the structure, which is similar to how common electrical wires are designed—except at a scale of a few micrometers in diameter.

COVID-19 Connection

The sensors can be attached to a mobile phone, for example, to collect breath pattern information, sound, and images at the same time. This type of health-monitoring information can be critical to monitoring COVID-19 patients without the need for in-person doctor visits or for health professionals to come in physical contact with them, which provides a layer of protection.

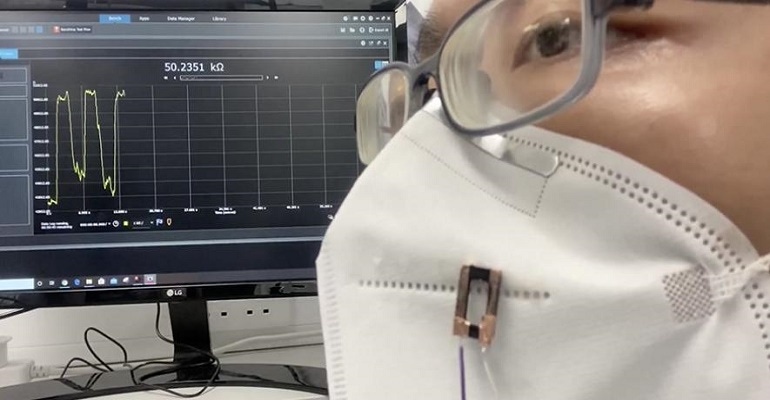

In fact, the team already have tested the sensors on a face covering worn by another scientist on the project, Andy Wang, a PhD student on Huang’s team. The sensor detected respiratory conditions such as normal breathing, rapid breathing, and simulated coughing, which are important to help monitor the health of COVID-19 patients.

The sensor also detected the amount of breath moisture that leaked through the face covering, which could help expose weak areas of protection in face masks being worn to help stop the transmission of COVID-19.

The technique and technology is a breakthrough in using conducting fibers to develop sensors, which to date have been difficult to fabricate by printing as well as to incorporate into devices and manufacture for scale, Huang said.

“Sensors made from small conducting fibers are especially useful for volumetric sensing of fluid and gas in 3D, compared to conventional thin-film techniques,” she said in a press statement.

In their tests, the team discovered that most fabric or surgical masks leak in the front, especially when the person wearing the mask is coughing. However, N95 masks tend to leak from the top and sides, according to the sensor’s monitoring data.

Beyond Health Monitoring

Researchers published a paper on their work in the journal Science Advances.

Because the sensors are “lightweight, cheap, small and easy to use” they also could be turned into home-testing devices that would allow people “to perform self-administered tests to get information about their environments,” Huang said, such as testing for air quality and the like.

The printing technique the team used goes beyond sensors. It also can be applied to developing biocompatible fibers of a similar dimension to biological cells that can enable the fibers to guide cell movements.

They also can be used to design novel electronics. Since the fibers are so tiny they are invisible to the naked eye, when they are used to connect small electronic elements in 3D, it would seem that the electronics are “floating” in mid-air.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 20 years. She has lived and worked as a professional journalist in Phoenix, San Francisco, and New York City. In her free time, she enjoys surfing, traveling, music, yoga, and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like