Researchers at the University of Southern California (USC) have developed a 3D printed rubber material that has the ability to repair itself. The elastomer has the potential to decrease manufacturing time and increase longevity for the likes of shoes, tires, soft robotics and electronics. The self-healable materials were 3D printed using a customized photopolymerization process.

“There is competition between these two behaviors,” explained Qiming Wang, Assistant Professor at USC. “And eventually we found the ratio that can enable both high self-healing and relatively rapid photopolymerization.”

Altering photopolymerization to develop self-healing disulfides

The paper detailing these materials focuses on the photopolymerization reaction of the alcohol-analogous thiol chemical group. The researchers added an oxidizer to the process, which transformed the thiols into a different group of chemicals called disulfides. This new group of chemicals has the ability to reform when broken, enabling self-healing. However the team had to distinguish the correct ratio between the two groups so that no properties were diminished.

“When we gradually increase the oxidant, the self-healing behavior becomes stronger, but the photopolymerization behavior becomes weaker,” described Wang.

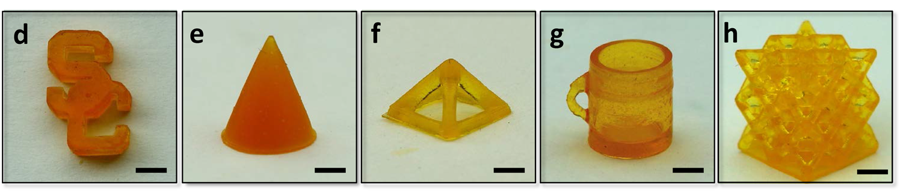

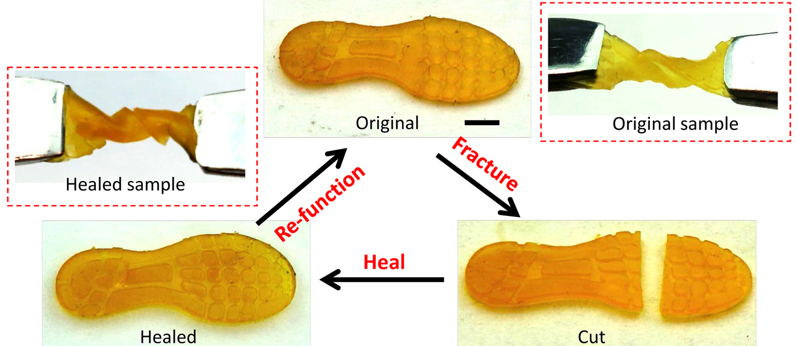

The researchers produced a study where they show the material’s ability on a range of products. The different items were cut in half, and after 2 hours, at 60 degrees Celsius, the products were able to heal completely. The repair time is variable depending on the temperature.

“We actually show that under different temperatures — from 40 degrees Celsius to 60 degrees Celsius — the material can heal to almost 100 percent,” said Kunhao Yu, a USC Viterbi student who was first-author of the study and is studying structural engineering.

“By changing the temperature, we can manipulate the healing speed, even under room temperature the material can still self-heal”

3D printing self-healing materials

3D printing is a key factor in a body of research looking to realize self-healing materials. In 2017, University of Manitoba researchers developed a 3D printable, conductive self-healing (CSH) hydrogel from chitosan, which is found in the shells of crabs, shrimp and other crustaceans. And, at the University of Melbourne, a team found that synthetic benzaldehyde, typically obtained by extraction from cinnamon oil, was a key ingredient to developing a 3D printable healing gel.

The latest work from USC at developing self-healing materials was published in a research paper titled Additive manufacturing of self-healing elastomers. The study was published in NPG Asia Materials, co-authored by Assistant Professor Qiming Wang; USC Viterbi students Kunhao Yu, An Xin and Haixu Du, and University of Connecticut Assistant Professor Ying Li. The university have recently engaged in other projects utilising 3D printing as well. In December 2018, USC Viterbi had been building a fleet of 3D printed rocket engines made entirely on campus in Los Angeles.

Impressed by USC Viterbi’s application of 3D printing? Nominate them for the 3D Printing Awards 2019.

For the latest news on 3D printing, subscribe to our 3D printing newsletter. You can also join us on Facebook and Twitter.

Visit our 3D Printing Jobs site for a new career in additive manufacturing.

Featured image shows a severed 3D printed shoe repairing itself. Image via An Xin and Kunhao Yu.