Wearable electronics may soon have another alternative to cumbersome batteries for power with the development of a new ultra-thin solar cell flexible enough to wrap around a pencil.

July 1, 2016

Researchers at the Gwangju Institute of Science and Technology in South Korea designed the cell, which is about 1 micrometer thick, or much thinner even than an average human hair. In contrast, standard photovoltaics are usually hundreds of times thicker, and even most other thin photovoltaics are two to four times thicker, they said.

The team envisions the technology as a versatile form of power for wearable devices such as smart glasses, fitness trackers, and watches because of its flexibility, strength, and small footprint.

“Wearable flexible electronics often require sustainable power sources that are also mechanically flexible to survive the extreme bending that accompanies their general use,” the team -- led by Jongho Lee, an engineer at the institute -- explained in an abstract for a paper about their work published in the journal, Applied Physics Letters. “In general, thinner microelectronic devices are under less strain when bent.”

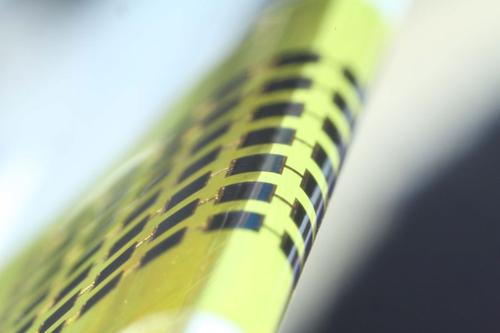

Researchers in South Korea have developed ultra-thin solar cells that are flexible enough to bend around small objects, such as the edge of a glass slide, shown here, or a pencil. The team of engineers that designed the cell thinks it can be a power source for wearable devices.

(Source: Juho Kim, Applied Physics Letters)

Indeed, in tests to see how far the cells could bend, the team discovered that they could wrap around a radius as small as 1.4 mm. Moreover, the strain on the thin cell was less than that put on thicker materials, about one-fourth the amount of strain than on similar cells about 3.5 micrometers thick.

“The thinner cells are less fragile under bending, but perform similarly or even slightly better,” Lee said.

Lee’s team created the cells from the semiconductor gallium arsenide, the same material photovoltaics company Sol Voltaics used to develop nanowire thin film that can boost the performance of photovoltaic cells. To achieve the desired girth of the cell, researchers stamped them directly onto a flexible substrate without an adhesive, which would have added thickness, they said.

To create a bond without adhesive material, the cells were cold-welded -- a process that joins two pieces of metal by forcing them together so hard that the surface oxide films are disrupted and adhesion occurs -- to the electrode on the substrate. The process researchers used applied pressure at 170C (338F) and melted a top layer of material called photoresist to act as a temporary adhesive. Later that material was peeled away, leaving a direct metal-to-metal bond, according to researchers.

READ MORE ARTICLES ON SOLAR ENERGY:

The resultant bond serves a dual purpose in the cells, not only keeping the material together, but also serving as a reflector to direct stray photons back to the solar cells. This allows the conversion efficiency of the cell to be on par with similar, thicker photovoltaic cells.

This transfer-printing method of producing the cells is unique in how other thin solar cells have been designed, according to researchers. While a few other groups have reported the development of cells with a similar 1-micrometer thickness, their methods for fabrication were different, according to Lee. Using transfer printing requires a smaller amount of materials than these other methods, he said.

Elizabeth Montalbano is a freelance writer who has written about technology and culture for more than 15 years. She has lived and worked as a professional journalist in Phoenix, San Francisco and New York City. In her free time she enjoys surfing, traveling, music, yoga and cooking. She currently resides in a village on the southwest coast of Portugal.

About the Author(s)

You May Also Like