Abstract

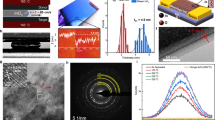

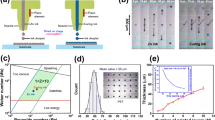

Indium tin oxide (ITO) is a transparent conductor used in applications such as touch screens, smart windows and displays. A key limitation of ITO is its brittle nature, which prohibits its use in flexible electronics. The commercial deposition of high-quality ITO also currently relies on a costly vacuum manufacturing approach. Here we report the centimetre-scale synthesis of flexible two-dimensional ITO using a low-temperature liquid metal printing technique. The approach can directly deposit monolayer or bilayer ITO onto desired substrates, with the resulting bilayer samples offering a transparency above 99.3% and a sheet resistance as low as 5.4 kΩ □−1. We also show that the bilayer ITO features a stratified structure with a pronounced van der Waals spacing. To illustrate the capabilities of the technique, we develop a capacitive touch screen using centimetre-sized monolayer ITO sheets.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 12 digital issues and online access to articles

$119.00 per year

only $9.92 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

The data that support the plots within this paper and other findings of this study are available from the corresponding author upon reasonable request.

References

Dixon, S. C., Scanlon, D. O., Carmalt, C. J. & Parkin, I. P. n-Type doped transparent conducting binary oxides: an overview. J. Mater. Chem. C. 4, 6946–6961 (2016).

Zheng, Q. & Kim, J.-K. Graphene for Transparent Conductors: Synthesis, Properties and Applications Vol. 23 (Springer, 2015).

Ellmer, K. Past achievements and future challenges in the development of optically transparent electrodes. Nat. Photon. 6, 809–817 (2012).

Lampert, C. M. Heat mirror coatings for energy conserving windows. Sol. Energy Mater. 6, 1–41 (1981).

Lewis, B. G. & Paine, D. C. Applications and processing of transparent conducting oxides. MRS Bull. 25, 22–27 (2000).

Greenham, N. C., Moratti, S. C., Bradley, D. D. C., Friend, R. H. & Holmes, A. B. Efficient light-emitting diodes based on polymers with high electron affinities. Nature 365, 628–630 (1993).

Yu, Z. et al. Indium tin oxide as a semiconductor material in efficient p-type dye-sensitized solar cells. NPG Asia Mater. 8, e305 (2016).

Niklasson, G. A. & Granqvist, C. G. Electrochromics for smart windows: thin films of tungsten oxide and nickel oxide, and devices based on these. J. Mater. Chem. 17, 127–156 (2007).

Guo, P., Schaller, R. D., Ketterson, J. B. & Chang, R. P. H. Ultrafast switching of tunable infrared plasmons in indium tin oxide nanorod arrays with large absolute amplitude. Nat. Photon. 10, 267–273 (2016).

Naik, G. V., Shalaev, V. M. & Boltasseva, A. Alternative plasmonic materials: beyond gold and silver. Adv. Mater. 25, 3264–3294 (2013).

Alam, M. Z., De Leon, I. & Boyd, R. W. Large optical nonlinearity of indium tin oxide in its epsilon-near-zero region. Science 352, 795–797 (2016).

Srinivasan, V., Pamula, V. K. & Fair, R. B. An integrated digital microfluidic lab-on-a-chip for clinical diagnostics on human physiological fluids. Lab Chip 4, 310–315 (2004).

Kumar, A. & Zhou, C. The race to replace tin-doped indium oxide: which material will win? ACS Nano 4, 11–14 (2010).

Shigesato, Y., Takaki, S. & Haranou, T. Crystallinity and electrical properties of tin-doped indium oxide films deposited by DC magnetron sputtering. Appl. Surf. Sci. 48-49, 269–275 (1991).

Tahar, R. B. H., Ban, T., Ohya, Y. & Takahashi, Y. Tin doped indium oxide thin films: electrical properties. J. Appl. Phys. 83, 2631–2645 (1998).

Wen, L., Sahu, B. B. & Han, J. G. Development and utility of a new 3-D magnetron source for high rate deposition of highly conductive ITO thin films near room temperature. Phys. Chem. Chem. Phys. 20, 4818–4830 (2018).

Cairns, D. R. et al. Strain-dependent electrical resistance of tin-doped indium oxide on polymer substrates. Appl. Phys. Lett. 76, 1425–1427 (2000).

Werner, T. T., Mudd, G. M. & Jowitt, S. M. Indium: key issues in assessing mineral resources and long-term supply from recycling. Trans. Inst. Min. Metall. B 124, 213–226 (2015).

Bae, S. et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 5, 574–578 (2010).

Wang, X., Zhi, L. & Müllen, K. Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett. 8, 323–327 (2008).

Wu, Z. et al. Transparent, conductive carbon nanotube films. Science 305, 1273–1276 (2004).

Hecht, D. S., Hu, L. & Irvin, G. Emerging transparent electrodes based on thin films of carbon nanotubes, graphene and metallic nanostructures. Adv. Mater. 23, 1482–1513 (2011).

Wu, H. et al. A transparent electrode based on a metal nanotrough network. Nat. Nanotechnol. 8, 421–425 (2013).

Margulis, G. Y. et al. Spray deposition of silver nanowire electrodes for semitransparent solid-state dye-sensitized solar cells. Adv. Energy Mater. 3, 1657–1663 (2013).

Morgenstern, F. S. F. et al. Ag-nanowire films coated with ZnO nanoparticles as a transparent electrode for solar cells. Appl. Phys. Lett. 99, 183307 (2011).

Khrapach, I. et al. Novel highly conductive and transparent graphene-based conductors. Adv. Mater. 24, 2844–2849 (2012).

Cao, C. et al. Nonlinear fracture toughness measurement and crack propagation resistance of functionalized graphene multilayers. Sci. Adv. 4, eaao7202 (2018).

Charalampos, A., Kaihao, Z., Matthew, R. & Sameh, T. Tailoring the mechanical properties of 2D materials and heterostructures. 2D Mater. 5, 032005 (2018).

Daeneke, T. et al. Wafer-scale synthesis of semiconducting SnO monolayers from interfacial oxide layers of metallic liquid tin. ACS Nano 11, 10974–10983 (2017).

Carey, B. J. et al. Wafer-scale two-dimensional semiconductors from printed oxide skin of liquid metals. Nat. Commun. 8, 14482 (2017).

Syed, N. et al. Wafer-sized ultrathin gallium and indium nitride nanosheets through the ammonolysis of liquid metal derived oxides. J. Am. Chem. Soc. 141, 104–108 (2019).

Syed, N. et al. Printing two-dimensional gallium phosphate out of liquid metal. Nat. Commun. 9, 3618 (2018).

Zavabeti, A. et al. A liquid metal reaction environment for the room-temperature synthesis of atomically thin metal oxides. Science 358, 332–335 (2017).

Daeneke, T. et al. Liquid metals: fundamentals and applications in chemistry. Chem. Soc. Rev. 47, 4073–4111 (2018).

Preuß, A., Adolphi, B. & Wegener, T. The kinetic of the oxidation of InSn48. Fresenius J. Anal. Chem. 353, 399–402 (1995).

Nadaud, N., Lequeux, N., Nanot, M., Jové, J. & Roisnel, T. Structural studies of tin-doped indium oxide (ITO) and In4Sn3O12. J. Solid State Chem. 135, 140–148 (1998).

Chen, Z. et al. Fabrication of highly transparent and conductive indium-tin oxide thin films with a high figure of merit via solution processing. Langmuir 29, 13836–13842 (2013).

Haacke, G. New figure of merit for transparent conductors. J. Appl. Phys. 47, 4086–4089 (1976).

Rokni, H. & Lu, W. Layer-by-layer insight into electrostatic charge distribution of few-layer graphene. Sci. Rep. 7, 42821 (2017).

Lee, P. A. & Ramakrishnan, T. Disordered electronic systems. Rev. Mod. Phys. 57, 287 (1985).

Dovesi, R. et al. CRYSTAL14: a program for the ab initio investigation of crystalline solids. Int. J. Quantum Chem. 114, 1287–1317 (2014).

Dovesi, R. et al. CRYSTAL14 User’s Manual (Univ. Torino, 2014).

Becke, A. D. Density-functional thermochemistry. III. The role of exact exchange. J. Chem. Phys. 98, 5648–5652 (1993).

Laun, J., Vilela Oliveira, D. & Bredow, T. Consistent Gaussian basis sets of double-and triple-zeta valence with polarization quality of the fifth period for solid-state calculations. J. Comput. Chem. 39, 1285–1290 (2018).

CRYSTAL – Basis Sets Library (CRYSTAL - Theoretical Chemistry Group, Univ. Torino, acessed 20 November 2019); http://www.crystal.unito.it/basis-sets.php

Monkhorst, H. J. & Pack, J. D. Special points for Brillouin-zone integrations. Phys. Rev. B 13, 5188 (1976).

Crystallography Open Database COD ID 231009 (COD, Vilnius Univ., accessed 20 November 2019); www.crystallography.net

Marezio, M. Refinement of the crystal structure of In2O3 at two wavelengths. Acta Crystallogr. 20, 723–728 (1966).

Acknowledgements

We acknowledge technical support and instrumentation access provided by the RMIT Microscopy and Microanalysis Facility (RMMF) and MicroNano Research Facility (MNRF) at RMIT University. T.D. acknowledges funding received through the ARC DECRA scheme (DE190100100). We also acknowledge financial support received from the ARC Centre of Excellence FLEET (CE170100039). D.E. acknowledges the Scientia Fellowship scheme at the University of New South Wales. N.S. and A.Z. acknowledge funding from the Australian Government Research Training Program Scholarship scheme. S.P.R. is supported by the ARC (CE170100026). This work was also supported by computational resources provided by the Australian Government through the National Computational Infrastructure National Facility and the Pawsey Supercomputer Centre. This work was performed in part at the Melbourne Centre for Nanofabrication (MCN) in the Victorian Node of the Australian National Fabrication Facility (ANFF).

Author information

Authors and Affiliations

Contributions

The project was conceived, designed and directed by T.D., K.K.-Z. and D.E. R.S.D. and N.S. designed the synthesis methodology, experiments and device fabrications. R.S.D. synthesized monolayer 2D ITO and conducted AFM, flexible device fabrication and electrical measurements. N.S. synthesized bilayer 2D ITO, conducted a detailed AFM study of bilayer 2D ITO and fabricated devices for Hall effect measurements. A.Z. conducted TEM/SAED and HRTEM imaging and contributed to creating schematic illustrations. A.J. assisted with electronic device design and manufacture. M.M. contributed to device design and schematic illustrations. M.R. contributed to capacitive touch screen measurements. B.Y.Z. performed XPS measurements. M.A.R. contributed to four-point-probe measurements. P.A. assisted in the analysis of data and method development. K.A.M. contributed to device fabrication. M.B.G. performed cross-sectional TEM imaging. E.D.G. performed and analysed optical measurements. S.B. conducted Hall effect measurements and RIE etching. M.S.F. analysed and interpreted Hall effect data together with S.B. S.P.R. performed DFT calculations. C.F.M. contributed to the analysis of XPS data and contributed to the development of the theoretical framework. T.D., K.K.-Z., D.E., R.S.D. and N.S. analysed the results and prepared the manuscript. All authors revised the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Supplementary Information

Supplementary Figs. 1–13, Notes 1–3 and Table 1.

Rights and permissions

About this article

Cite this article

Datta, R.S., Syed, N., Zavabeti, A. et al. Flexible two-dimensional indium tin oxide fabricated using a liquid metal printing technique. Nat Electron 3, 51–58 (2020). https://doi.org/10.1038/s41928-019-0353-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41928-019-0353-8

This article is cited by

-

Large second-order susceptibility from a quantized indium tin oxide monolayer

Nature Nanotechnology (2024)

-

Investigation on preparation and performance of high-reliable ZnO–NiO@Cu NW flexible transparent conductive thin films

Journal of Materials Science: Materials in Electronics (2024)

-

Flexible, Transparent and Conductive Metal Mesh Films with Ultra-High FoM for Stretchable Heating and Electromagnetic Interference Shielding

Nano-Micro Letters (2024)

-

Far-infrared transparent conductors

Light: Science & Applications (2023)

-

Flexible thermoelectric generator and energy management electronics powered by body heat

Microsystems & Nanoengineering (2023)