Solar-to-hydrogen production from water and light was 17.6% efficient, despite the relatively humble solar materials involved – silicon and perovskite – compared to a 20% target set by the US Department of Energy for 2020. According to the research team, which is from Australian National University (ANU), a III-V semiconductor solar demonstrator elsewhere has achieved 19% conversion.

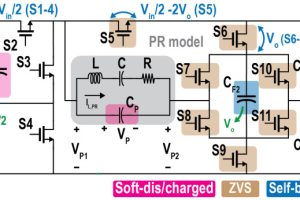

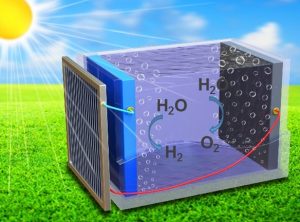

The technology is photo-electro-chemical hydrogen production, where, essentially, a solar panel is directly used as one wall of an electrolysis cell.

In the diagram (above right) temporarily ignore the perovskite booster solar cell spaced away at the left end of the electrolyte tank. The thick blue layer behind it represents the custom silicon ‘solar cathode’ created at ANU for this application.

The positive electrode on the external face of the solar cathode cell is more like that of a standard solar cell, and is available to be connected to the electrolyte tank’s anode (black, right of diagram).

The solar cathode’s negative electrode, at the rear of the solar cell, is special as it is designed for reliable hydrogen production in a liquid environment – it has a catalytic platinum-over-titanium coating, for example.

Inside, the solar cathode has a buried junction (it has a n+/n/p+ structure) and a micro-pyramidal upper surface to increase light absorption, with Al2O3 passivation and a Si3N4 anti-reflection coating.

Even without its perovskite partner, this silicon cell can achieve a 14.1% solar-to-hydrogen score, although its output voltage is insufficient to split water – requiring an additional voltage source connected in series between it and the tank’s anode to create hydrogen – as an aside, to split water on its own, a single solar cell would need to have a bandgap of >2.0eV, and thus could not absorb much of the solar spectrum.

In ANU’s tandem arrangement, it is the perovskite front cell that provides additional potential to the solar cathode for water splitting.

As with all tandem solar cells, the front cell is there to absorb solar wavelengths to which the rear cell is not sensitive, while passing wavelengths that it is sensitive to.

To harmonise with the optical and electrical characteristics of the silicon cell, a custom high bandgap (~1.75eV) perovkite solar cell was created, and it was this in series with the silicon cathode achieved 17.6% using only the sun’s energy – without needing an additional voltage source.

This compares well with the maximum theoretical solar-to-hydrogen efficacy score using tandem cells, which is around 25%.

Now the team seeks to replace some of the remaining exotic materials in its tandem cell with more plentiful substitutes.

“Modelling and analysis of the dual-absorber stand-alone photo-electro-chemical system shows that there are ample opportunities for further optimisation of the materials and performance, with a potential to accomplish an solar-to-hydrogen efficiency of over 20% using all low-cost materials,” according to the paper ‘Over 17% efficiency stand-alone solar water splitting enabled by perovskite-silicon tandem absorbers’, which describes the work in Advanced Energy Materials. “With significant progress achieved recently on monolithic integration of perovskite to silicon for tandem PV cells, we envisage the proposed two component tandem architecture can be further simplified into a monolithic perovskite-Si photoelectrode.”

Direct sunlight to hydrogen conversion, which allows energy to be stored indefinitely as hydrogen, is seen as a way of matching intermittent solar availability to non-synchronised energy needs.

Over 17% efficiency stand-alone solar water splitting enabled by perovskite-silicon tandem absorbers is here. Only the abstract is available free.

ANU worked with Saudi Arabia’s King Abdullah University of Science & Technology (KAUST).

Electronics Weekly Electronics Design & Components Tech News

Electronics Weekly Electronics Design & Components Tech News