icks and shovels clanked against phosphate rock in pits 30 feet deep. Soaked in sweat, miners toiled in knee-deep slurry for 12-hour shifts. By 1919, they’d had enough of laboring under armed guards on horseback for little more than two dollars a day. They couldn’t stand to watch another co-worker maimed or killed in dynamite accidents. Their strike, in a sleepy Central Florida mining town called Mulberry, put a chokehold on the worldwide fertilizer trade for months.

A century later, Florida’s phosphate miners are highly trained technicians who sit in air-conditioned, 8-million-pound excavators. They unearth some 10 million tons of phosphate rock a year, supplying nearly a quarter of global demand for the “white gold” that helps crops grow.

Florida is home to one of the richest phosphate deposits in the world. For about 140 years, the state has housed a secluded and powerful industry that mines one of three essential nutrients for the global fertilizer market.

Today, wheelbarrows have given way to mammoth machinery. But there are still two sides to the white-gold coin. A century ago, Florida’s phosphate industry sacrificed miners, many of them impoverished men of color. Today, the sacrifices involve the environment, as excess phosphorus runoff causes toxic algae blooms around the world and the industry’s radioactive waste grows in mountains throughout central Florida.

So does Florida phosphate “feed the world,” an industry mantra, or pose serious threats? Throughout history and perhaps into the future, the answer has been both.

When giant sloths walked Florida

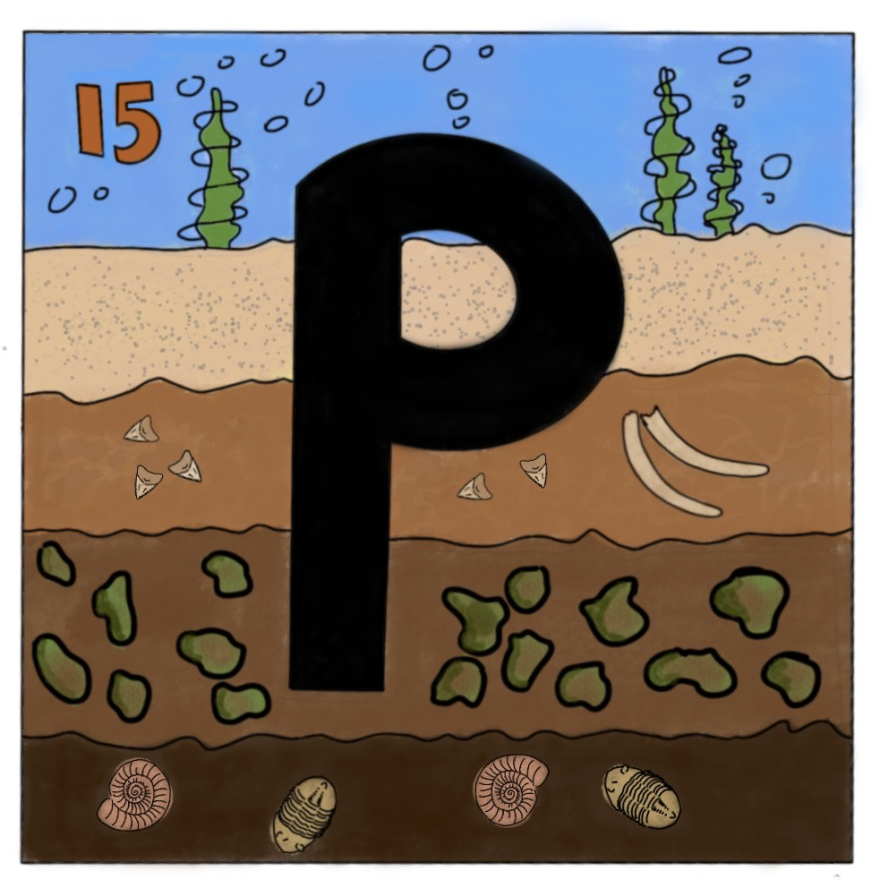

About 15 million years ago, all but a small strip of land down the center of what we know today as the Florida peninsula was covered in a warm, shallow sea. Giant sloths, small, three-toed horses and false saber-toothed cats commanded this strip. Underwater, prehistoric sharks and whales glided through the warm depths. Arthropods and mollusks scuttled along the seabed. This shallow sea of the Miocene age built the bed of limestone that the peninsula rests upon today.

Living in food-abundant upwelling areas, these marine creatures left an ancient gift. Their organic matter mineralized into phosphate-rich sediment deposits along interior Florida.

Fast forward millions of years. Early phosphate miners in the late 1800s began to unearth the bones of giant, 4-tusked elephants and fossilized imprints of primeval crabs. The Central Florida region became known as the Bone Valley.

READ MORE: WUFT special report — The Price of Plenty

Today, paleontologists have cataloged over 56,000 fossils from the area, according to Rachel Narducci, vertebrate paleontology collections manager at the Florida Museum of Natural History.

“These fossils never would have been found if it wasn’t for mining,” Narducci said.

Bone Valley is not a valley at all. In fact, it’s a high point in Florida, according to Narducci, but the deep crevices carved into the ground from mining operations gave it the appearance of something like a ghostly Grand Canyon. About 42 new species were described from its depths.

“It’s filling a gap in the fossil record that we just don’t have anything close to,” Narducci said.

Fossils from 18 million years ago and about 1 million years ago are well studied. Paleontological excavations from mining sites have shed light on the in-between. With so many changes in landmass and sea level during the Miocene age, it is hard to tell what creatures may have roamed the area before mining exhumed their remains.

Discovering P

We owe the discovery of phosphorus to an amateur alchemist and his search for the elusive Philosopher’s Stone — not the death-delaying artifact from the “Harry Potter” series, but a substance capable of turning base metals into gold. Henning Brandt, like many alchemists before him, was obsessed with finding the thing that would not only make its discoverer wildly rich, but cure illnesses and prolong life.

Around 1669, Brandt conducted a series of experiments that involved distilling human urine. He boiled 50 buckets of his own pee until they reduced to a thick syrup, heated that syrup until a red oil could be drawn off, and cooled the concoction until a black spongy top and salty bottom remained. He then discarded the salt, combined the red oil with the black spongy substance and heated it for about 16 hours. What spontaneously flamed into the air and faintly glowed green was a highly reactive, pure form of phosphorus that could be solidified by dunking into cold water.

Brandt had discovered Earth’s 13th element. (While P, also known as “The Devil’s Element,” was discovered 13th, it is No. 15 on the periodic table.)

Phosphorus is distinct from its fellow plant-sustaining nutrients, nitrogen and potassium. It cannot be synthetically produced. Despite its elusive nature, it is part of the basis of life on earth. On a molecular level, phosphate fortifies the links of human DNA and is found in bones and teeth as calcium phosphate salts. Plants rely on phosphorus for cell growth and energy conversion. Too little of it and crop yields suffer. Fruits don’t fully develop.

Until about the 1950s, fertilizer manufacturing operations were relatively small and tailored production to the agricultural needs in a given area, according to the Florida Industrial and Phosphate Research Institute. Now, phosphate rock is processed into chemical fertilizer when sulfuric acid is mixed with the rock in a reactor to produce the solid, crystalline compound of phosphoric acid, which is a phosphorus atom bound to five atoms of oxygen.

While most of the world’s supply of phosphate goes toward fertilizer production, it’s also an ingredient in animal feed, toothpaste, insecticides, food preservatives and a number of other common household items.

Rocks in the river, a strike in the mines

In the winter of 1881, engineers with the U.S Army Corps were surveying land for the construction of a possible canal through central Florida to Charlotte Harbor on the southwest coast. Along the Peace River, civil engineer Francis J. LeBaron was excited to discover a waterway with a seemingly endless bounty of fossils. LeBaron sent nine barrels and boxes of samples to professor S. F. Baird of the Smithsonian Institute, who was so intrigued that he ordered LeBaron to do a complete geological survey of the river. When LeBaron returned to the Peace River in 1886, he dug test pits and analyzed the sample deposits. He realized that the rock pebbles loaded with phosphate he pulled from the water were of immense value.

He turned to Jacksonville and Philadelphia-based capitalists and pressed for them to “buy or bond the entire Peace River Valley,” according to “Discovery of Florida Phosphate.”

Two years later, the first mining operation to extract phosphate from large rock formations popped up near Hawthorne, Florida, according to the Florida Department of Environmental Protection. Ground and river pebble mining began five years after that, around 1888.

Conditions at these sites were abysmal. Workers lived in wooden shacks and faced diseases like malaria. While white workers were present, Black miners bore the brunt of the work down in the pits, according to Edward “Ted” Melilo, the Willian R. Kenan Jr. professor of History and Environmental Studies at Amherst College.

"They go down in the phosphate mines and bring up the wet dust of the bones of prehistoric monsters, to make rich land in far places…”Zora Neale Hurston

Zora Neale Hurston, the preeminent early 20th century writer, documented folk songs and stories from laborers in the 1930s for the U.S. Works Progress Administration, or WPA.

Most famous are her descriptions of turpentine camps, the worksites dedicated to harvesting pine sap and resin for turpentine production. But in her autobiography “Dust Tracks on a Road” she writes of “sweating black bodies, muscled like gods, working to feed the hunger of the great tooth…They go down in the phosphate mines and bring up the wet dust of the bones of prehistoric monsters, to make rich land in far places…”

Hurston visited Polk County’s Mulberry for the WPA.

“The history of Mulberry begins with phosphate,” according to the Greater Mulberry Chamber of Commerce.

A railroad originally built to transport lumber and turpentine ran through the heart of Central Florida. Mid-point along the way, a Mulberry tree became a well-known meeting place and a mining town grew there, taking the tree’s name. The tree, no longer standing, also was the known site of lynchings.

At the turn of the century, tens of thousands of Black workers moved to Polk County seeking jobs in the area’s developing cypress mills, orange groves, turpentine camps and phosphate mines, according to Melilo.

In April of 1919, a group of about 3,000 Black and white union members went on strike against 17 Mulberry-based phosphate mining companies. Their demands followed recommendations by the National War Labor Board. They were asking for a minimum wage of 37 cents an hour and a reduction in work shifts to 8 hours a day. That would’ve doubled their wages and cut their daily work time between two and four hours.

When managers from two different companies refused to adhere to the demands, 1,800 phosphate miners walked off the job. Very little historical research has been done on this strike, according to Melilo. But it’s remarkable for being one of the only examples of successful multi-racial unionism during the First Red Scare, a period marked by widespread labor suppression and racial violence.

“This is a period of intense lynchings in U.S. history and yet, white and Black workers were going out on strike together demanding some pretty basic things,” Melilo says.

By early May, about 1,200 more workers from 14 other regional phosphate companies joined the strikers. Frustrated by the prolonged strike, the U.S. Department of Labor stepped in. The labor department’s mediator, J.W. Bridwell, and his team were unable to negotiate a settlement.

Two months after Bridwell’s efforts, in early August, phosphate mining companies began recruiting Black strikebreakers from Georgia. In one case, 300 laborers left Georgia but along the way, nearly 200 of them deserted after hearing they were headed for a highly contested picket line. Only 50 workers agreed to travel to the mines, escorted by armed sheriff’s deputies.

On the edge of a nearby city, Bartow, a group of strikers ambushed the cavalcade, killing one Georgia miner and wounding Deputy Sheriff Gordon Zebendon, a phosphate company guard.

In retaliation, four white company guards drove through the Black neighborhood of Mulberry and shot into homes at random with high-powered rifles.

“This is an incredibly violent affair,” Melilo says. “It was brutal stuff.”

A woman, Lula King, and the two-year-old child she was holding in her arms were shot. The child died. A former mine worker named Sam Benzley was wounded with a buckshot to the chest. The sheriff later caught the four company guards and jailed them in Bartow.

The tragic standoff ended on Dec. 3 when most of the phosphate companies agreed to a wage doubling and a reduction to the workday by at least two hours.

The strike’s consequences reverberated across the globe.

Melilo found that global trade journals covered the year 1919 as one of uncertainty for inadequate supplies and high fertilizer prices. The strike was also felt in the pockets of European farmers. Germany’s Secretary of Agriculture noted in 1920 that they had obtained only about 28% of the phosphoric acid fertilizer supply needed to sustain German farms.

Vanishing water

By the 1920s, technology began to replace physical labor as up to 8-million-pound ground-moving machines called draglines rumbled into Bone Valley. The enormous machines evoke a fantasy novel more than an industrial site. Draglines are mechanized to “walk” with feet across the landscape. Their enormous buckets scrape into Florida’s earth, leaving behind vast moonscapes. They increased mining capabilities by an order of magnitude.

Draglines move about 70 tons of material in each scoop, according to James Briscoe, senior operations manager at The Mosaic Company, one of only two mining companies remaining in Florida today.

“There’s only about 400 (draglines) in the world, and they haven’t built a new one since 1999,” said Briscoe.

Around the turn of the 20th century, mining engineers invented flotation, the now widely used process for extracting minerals by “floating” them away from contaminating ores. Flotation separates phosphate rock from sand by adding a fatty acid that adheres to phosphate, but not sand. Then, tiny air bubbles are injected into the tanks and adhere to the waxy-coated phosphate, causing it to rise.

It makes freshwater one of the most critical elements in phosphate mining. And water represented one of the earliest-seen environmental consequences of the industry. In the early 1950s, residents of Polk County watched Kissengen Spring in the Peace River watershed dry up over the course of a year and a half.

What was once a cool, crystal-clear deep blue spring turned into a stagnant, green mud hole amid intense groundwater pumping of the Floridan Aquifer, largely by phosphate mining companies.

This spring wasn’t just beautiful. It was an integral part of the local economy and community. Young kids and families came to the two-lane bowling alley, for the 75-cent chicken dinners or to take the 17-foot plunge into the springhead’s icy waters.

Native Ben Jackson began going to the spring when he was in diapers. Now 93, he recalls his first memory of Kissengen.

“I was about four or five years old,” Jackson remembers.. “It was so cold, I couldn’t forget it.”

When he was a teenager, during World War II, Jackson worked at the spring’s concession stand. His fondest memories of Kissingen are taking his high school sweetheart to the dancefloor where they’d sway along to “The Gypsy” sung by The Inkspots, their favorite tune.

More than half a century later, “every morning, when I go in to make coffee, I say ‘Alexa! play The Gypsy,’” he says. “It brings back memories.”

The next innovations

Today, profits are huge and demand for fertilizer has kept the industry pushing on in Florida for more than a century. Mining chews up between 3,000 and 6,000 acres of land a year in Florida. About 25% of that is wetlands or other surface water like streams,according to the DEP.

Twelve active phosphate mines are currently authorized in Florida, according to the DEP. Most are controlled by two main companies, Mosaic and Nutrien. They make Florida a key if somewhat hidden force in the global fertilizer market. Canada-based Nutrien (NYSE: NTR) reported net income of $7.7 billion in 2022. Mosaic, (NYSE: MOS), headquartered in Tampa, reported net income of $3.6 billion. Both fertilizer giants saw record profits last year as global fertilizer prices skyrocketed due to supply chain issues and Russian sanctions.

At the biggest mining operation in the Bone Valley, Mosaic’s Four Corners Mine, nine draglines work to strip away overburden and dredge up a matrix of sand, clay and phosphate pebble. The matrix is shot through a series of pipes about 10 to 20 miles long into a washer where the phosphate is screened and pumped into a slurry. Then, the slurry is spun into “hydro-cyclones” at a high G force where coarse sand and phosphate swirl to the bottom and exit. Excess water and clay are stored in settling ponds. The phosphate pebble is then sent to a “hydrosizer” where feed and water are injected into tanks that force fine particles to rise as coarse particles gently fall to the sizer’s underflow. Next, pebble goes through the flotation process before it’s finally ready for shipping to a chemical processing plant.

Mosaic produces about 8 million tons of finished phosphate a year in Florida with the capacity to produce up to 10 million tons, according to Keith Alam, Mosaic’s senior manager in engineering.

The company reports that it pumped an average 34 million gallons of groundwater every day in 2022 to make that product.

Beginning with labor in its early history and water in its modern history, innovations have helped the industry overcome certain sacrifices of the past. But so far, today’s crises associated with the phosphate industry have proved harder to solve.

From the Great Lakes, down the Mississippi River, to the dead zone in the Gulf of Mexico and toxic algae in Florida, nutrient pollution running off farms and landscapes is plaguing U.S. waterways and the people who rely on them. Mountains of phosphoric acid’s radioactive waste, known as phosphogypsum stacks, rise alongside Florida’s phosphate operations.

As the industry continues its search for white gold, with possible major expansion into the hunt for rare earth minerals, scientists and Floridians continue to search for solutions.

“It’s a food story, it’s a population story,” said Neil Beckingham, Mosaic's senior advisor for water technology. “And it’s a really complicated story.”

This story is part of The Price of Plenty, a special project investigating fertilizer from the University of Florida College of Journalism and Communications and the University of Missouri School of Journalism, supported by the Pulitzer Center’s nationwide Connected Coastlines reporting initiative.